Today, I….

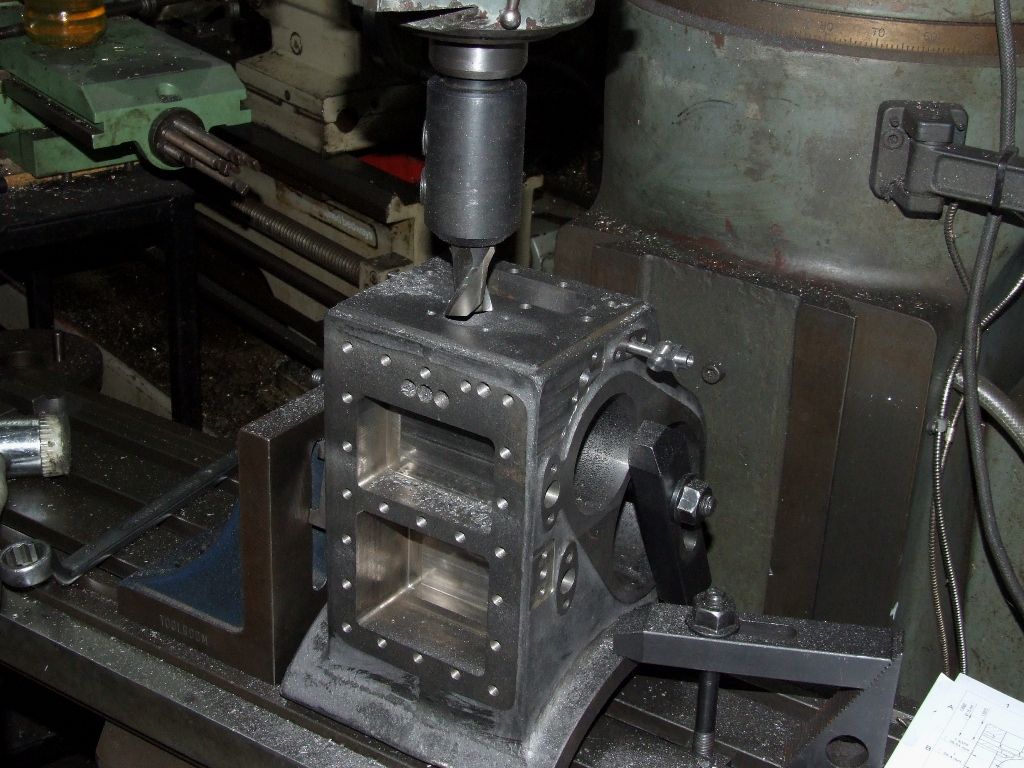

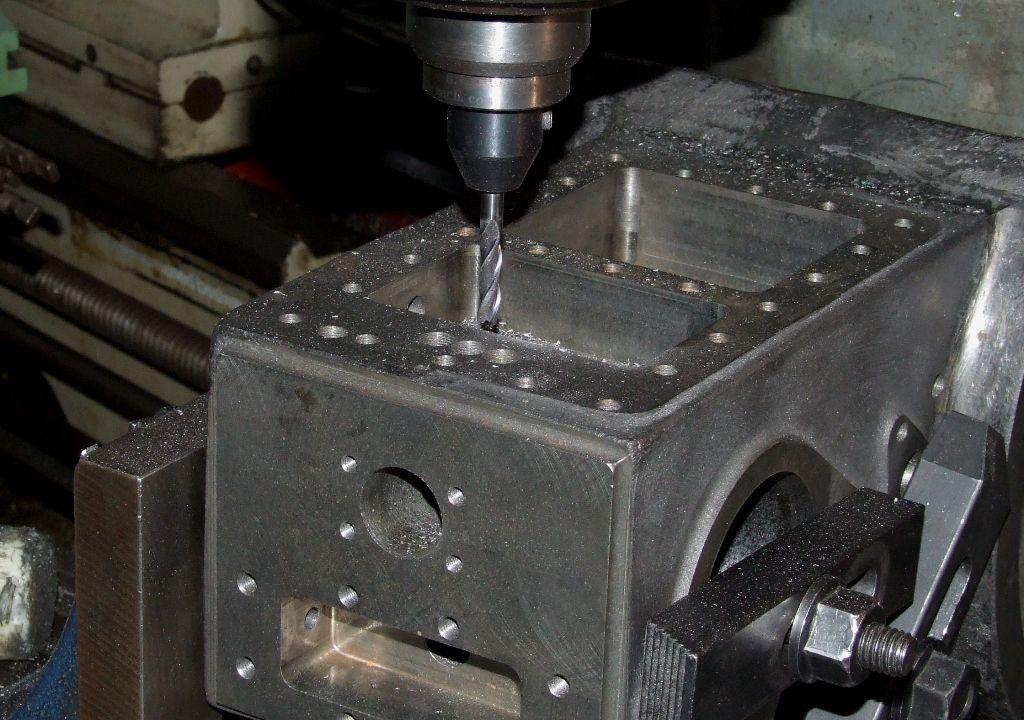

… Continued rebuilding my Denbigh H-something horizontal mill. In theory it is a model H4 Auto, the word meaning powered long feed by the usual wheel and worm driven via the usual telescopic, jointed shaft, from a small pulley and belt set on the back of the machine.

This example came from a bereavement sale. Its previous owner, a vehicle restorer, had left a steel shed full of remarkably rusty machine tools on a floor of earth and straw. So it was in a bit of a state, but serviceable after a fashion, driven by a confection of ancient single-phase motor, old 3-speed Ford car gearbox and motorcycle chain to a sprocket screwed to the original flat-belt pulley on the spindle.

It lacked all trace of the "auto" though, apart from a small embossed facing on the rear of the machine body, and the worm-wheel.

I identified the mill eventually thanks to Tony Griffiths, and last night returned to his lathes site to investigate further, with a view to re-worming the machine.

Mr. Griffiths remarks that some of Denbigh's milling-machines, intended as lower-cost for educational establishments and the like, lacked quality fits and finishes.

He's right there:

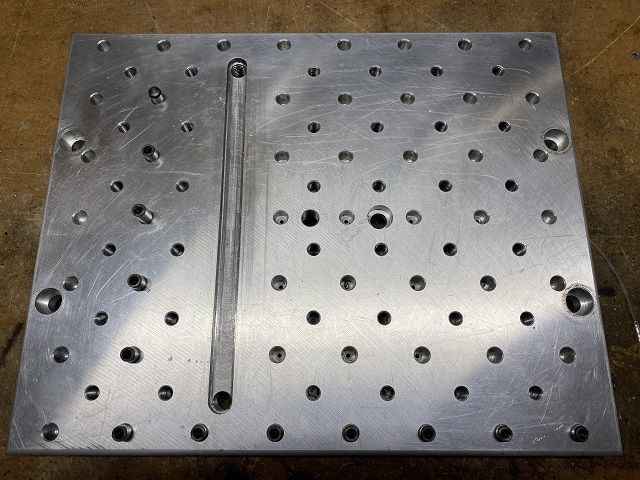

I wire-brushed the tatty paint-work back to bare metal and discovered that short of spending a lot of time and money on filler and sandpaper, no amount of painting will hide the roughness of the castings. Still, all my machine-tools are very much pre-loved and look it, and I can accept presentable rather than exhibition finish on an old machine-tool intended for using not admiring.

More annoying though, the 6 screw-holes in the threaded steel bush that is the knee-screw nut, were so out of angular pitch that despite their being well over their nominal 2BA clearance diameters, it took me several iterations to find the right rotational match for the part.

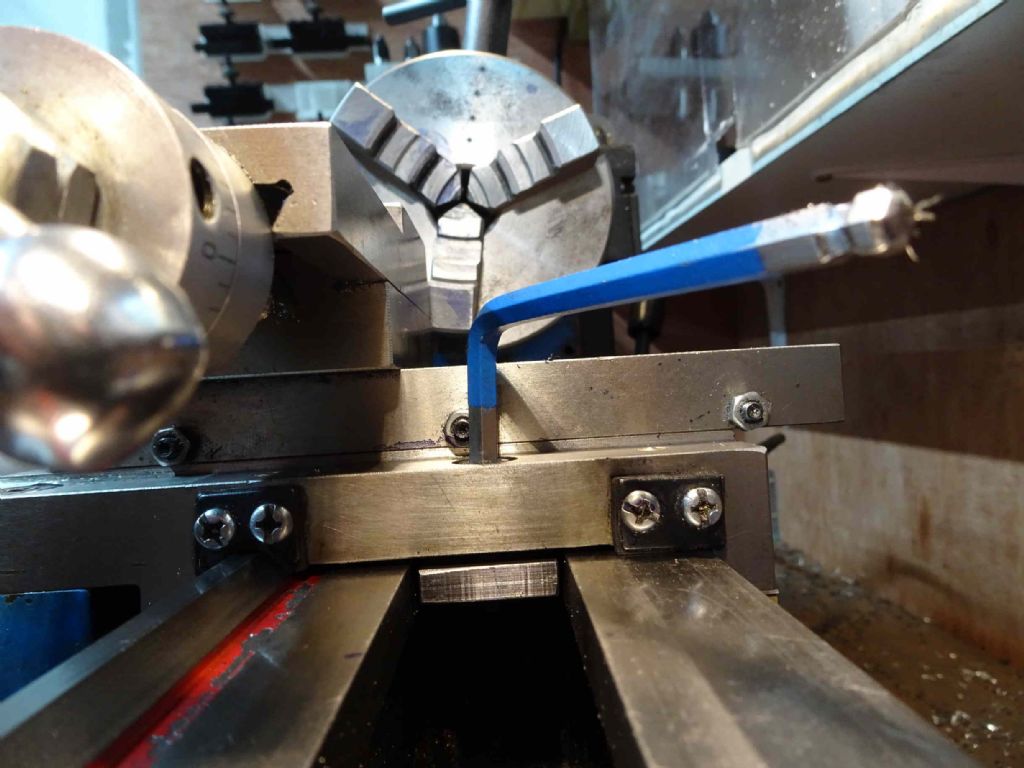

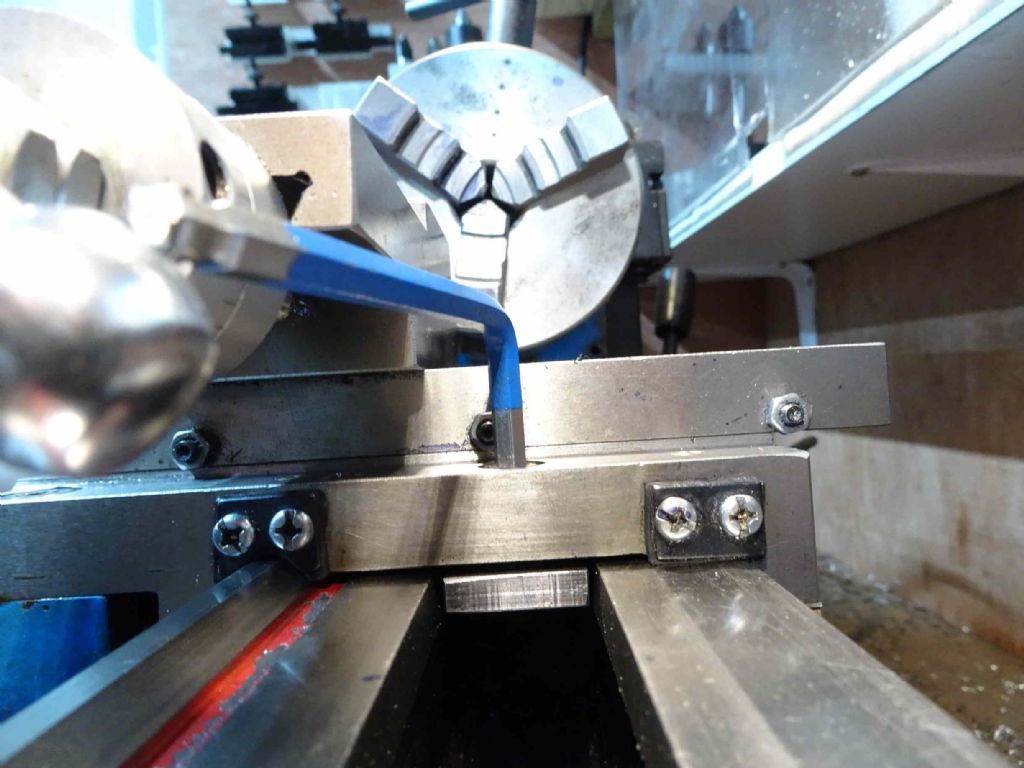

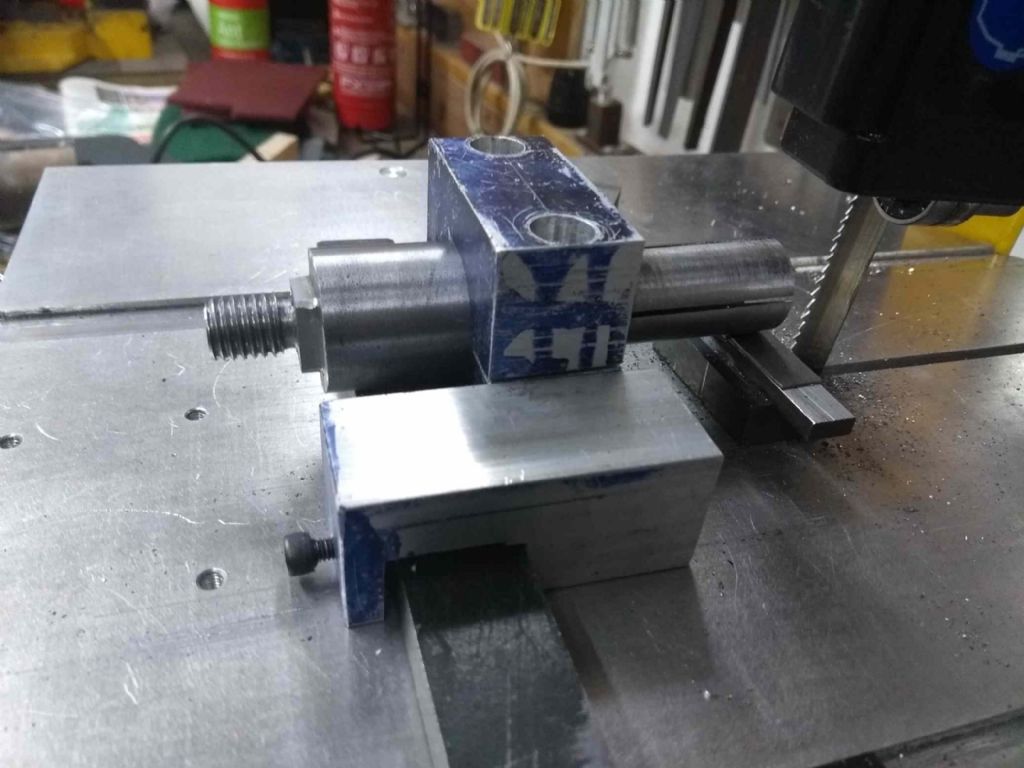

The research showed something odd though. Of the Denbigh H-series, only the H4 Auto had a longitudinal lead-screw, thanks to being an "Auto". The others had lever-action, manual feeds. I had assumed mine had simply lost its power-feed bits apart from the worm-wheel, over the years; but the lathes.co pictures clearly show the table on my machine also lacks its T-slot for the feed knock-off block.

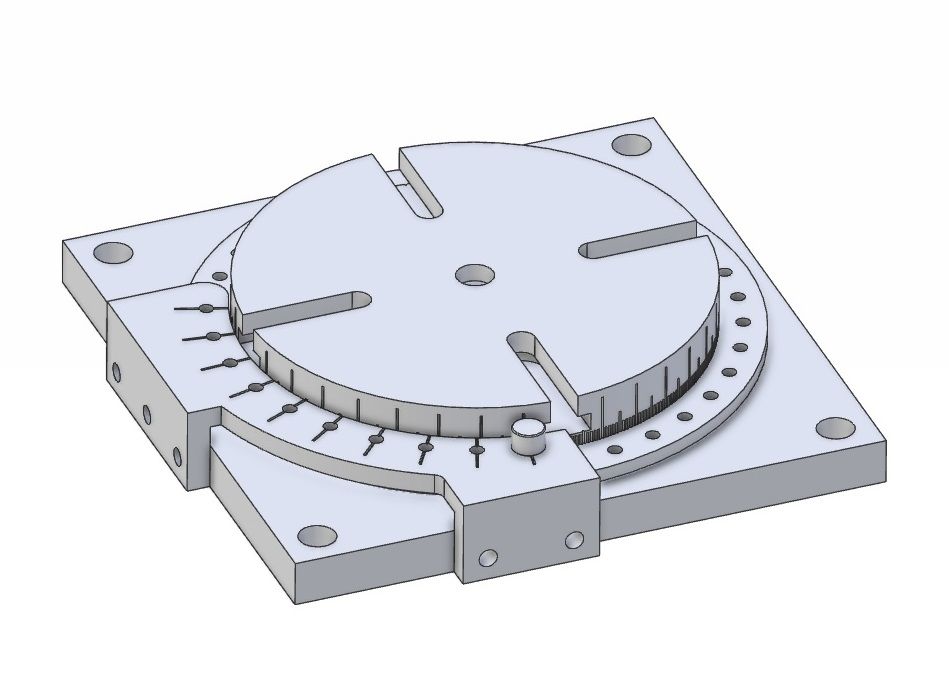

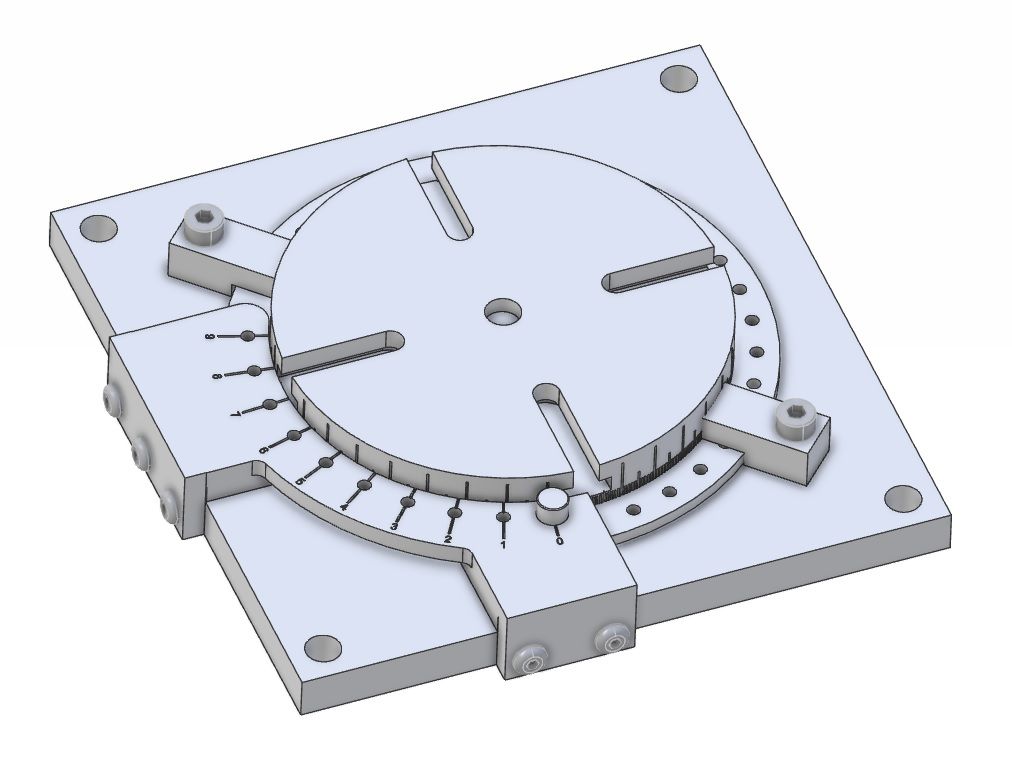

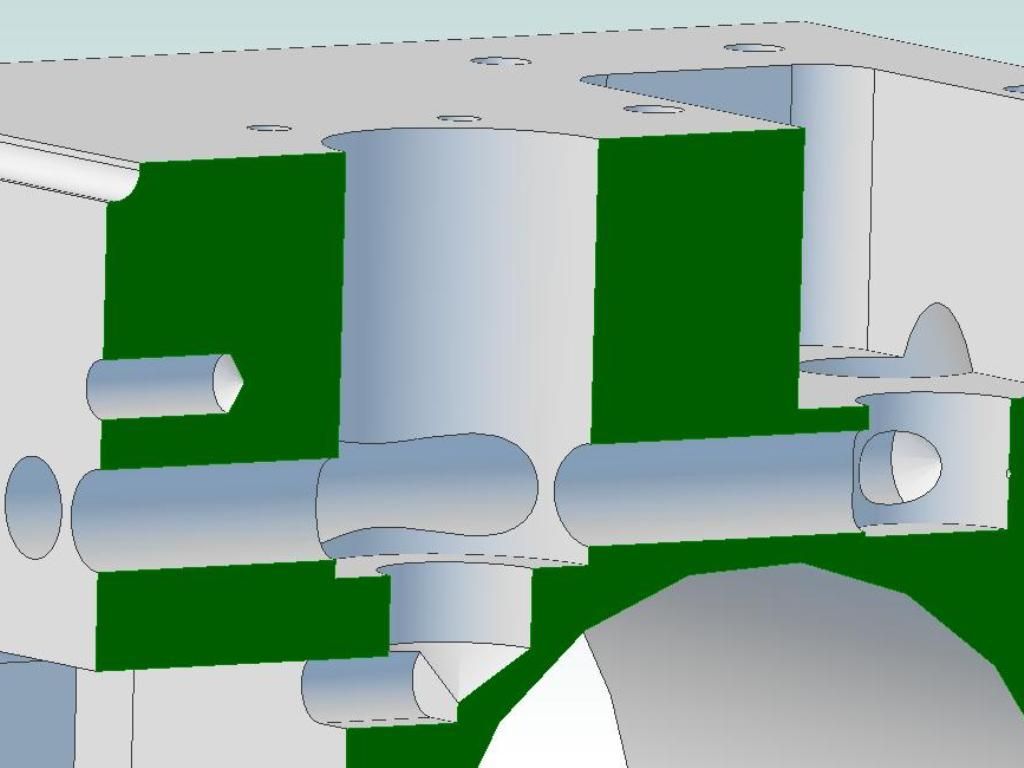

Strange. I will examine the table to see if like its companion parts it bears a stamped number 4 I assume is the model, not a batch, number. I have found no serial number either, nor signs of any lost number-plate. I wonder if the power-feed was an option that could be retro-fitted, using the tapped holes already there in the cross-slide and the facing on the back of the column, but why the "wrong" table? The table is for a screw-feed model as it has no features possibly associated with a lever-feed, but a plain underside, arched to clear the feed nut and worm bearing housings integral with the cross-slide. Yet has no slot for the travel-limiter.

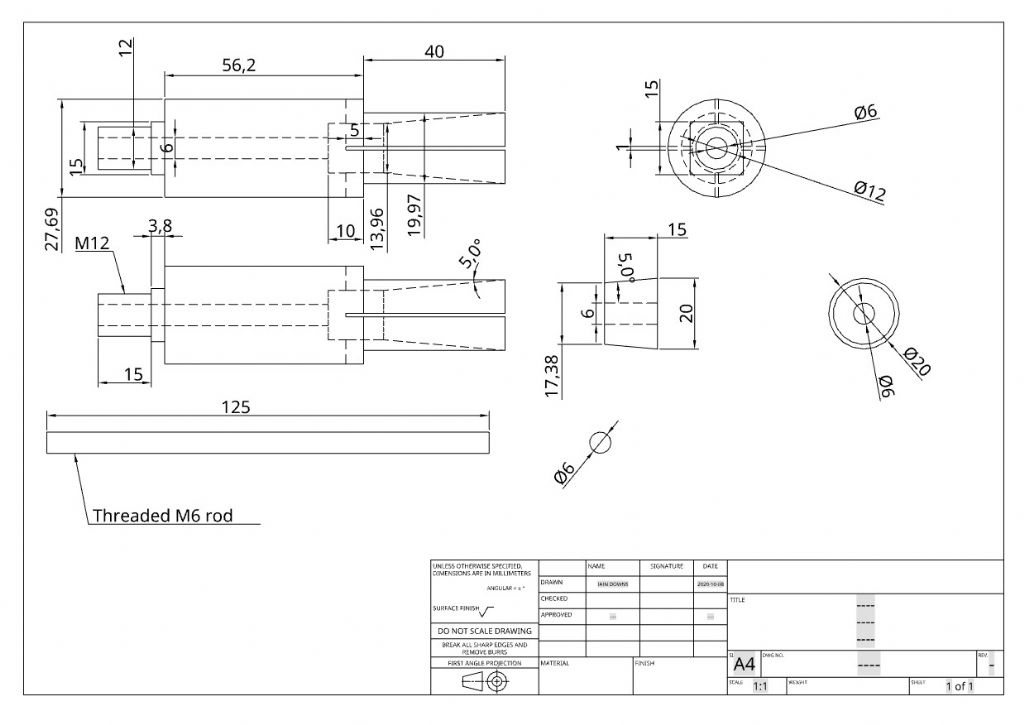

I would like to fit it with power-feed in keeping, but am not sure how to identify a worm matching the wheel (12DP? Approx 1.8" pcd, 22T). An orphaned worm I have, seems to fit but with a 2-start thread, it lies at an angle to the wheel, adding to the fun.

Nigel Graham 2.