The Tormach CNC Lathe attachment (Rapid Turn) is a much better accessory that it's predecessor which was a Mini Lathe adapted and equipped with 4th Axis capability, however it lacked power to do any serious work.The Rapid Turn is equipped with a 1 H.P. motor and is much more capable, however it lacks multiple tooling capability being equipped only with a single small quick change tool post that clamps to the spindle nose thus rendering it necessary to change tools between different operations.

Other people have made Gang tooling to suit so I decided to have a go at making my own. Here are the results so far.

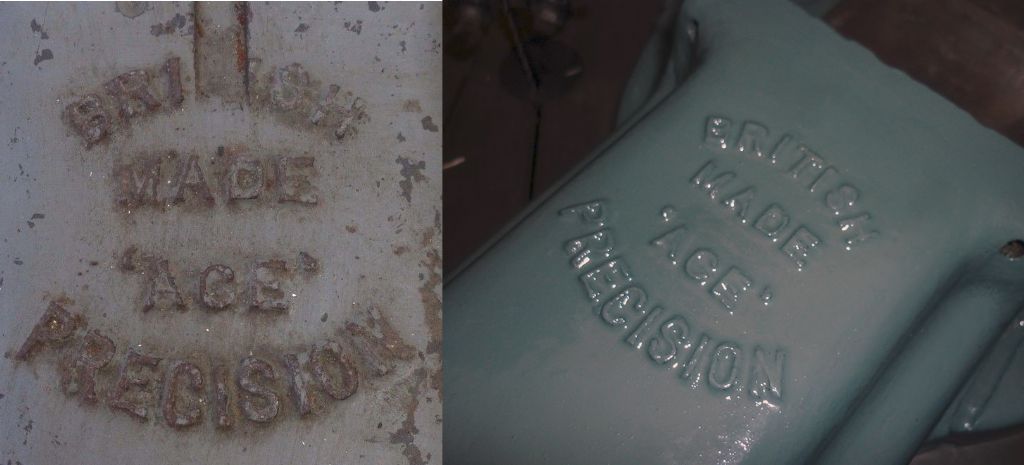

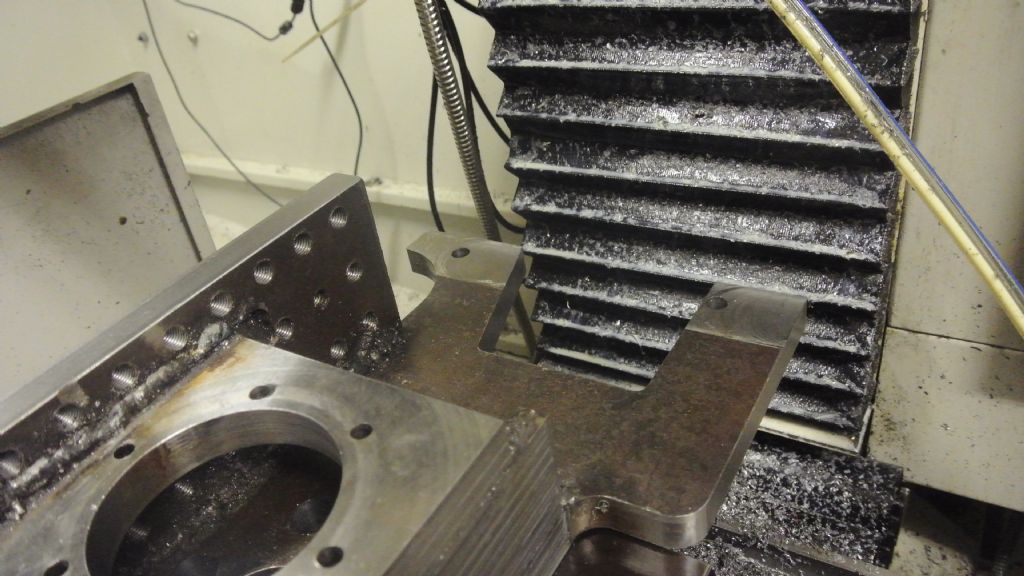

The holes that you see on the top plate are to permit long allen screws to be fitted into the bearing retain ring, though six holes are drilled only four are used leaving two permanently in the housing the lower plate is attached to two holes drilled and tapped in the rear of the travelling head. Note my scrambled egg welding.

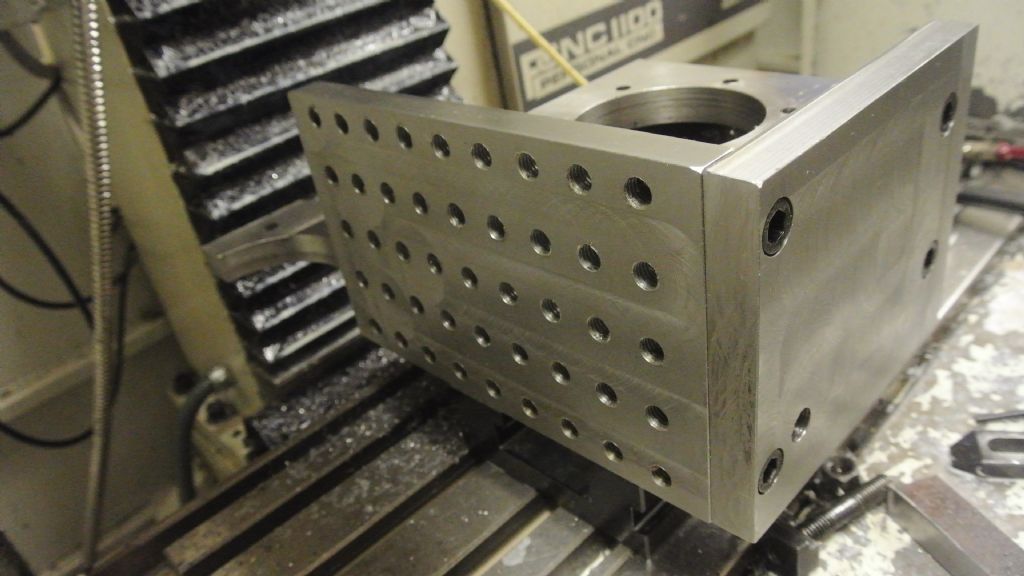

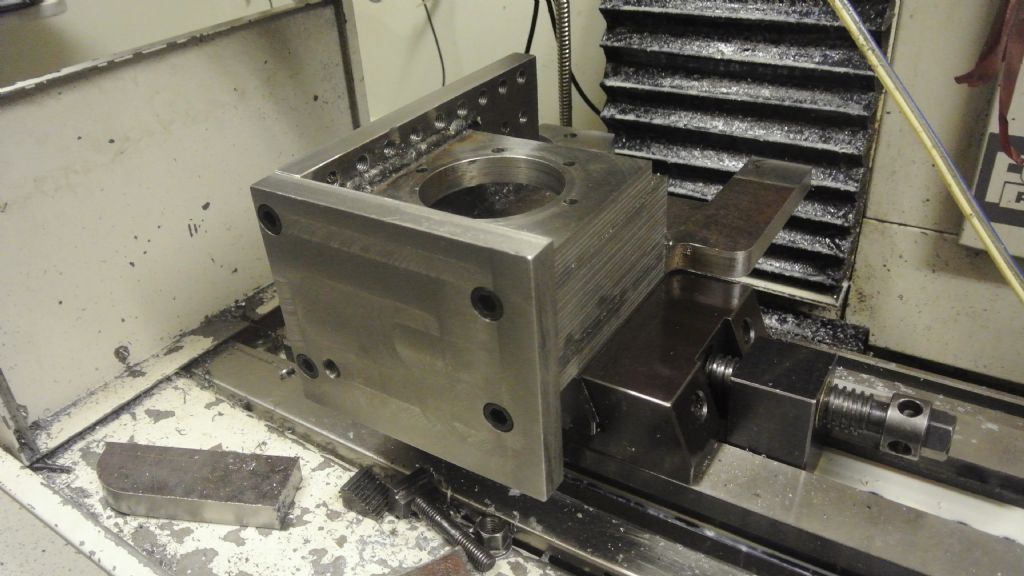

This view shows the side of the gang tooling fixture, the holes are all drilled and tapped M 12 to take allen bolts fitted through the tool holders and allow for the holders to be fitted at various heights nd distances along the Y axis.

This view shows the side of the gang tooling fixture, the holes are all drilled and tapped M 12 to take allen bolts fitted through the tool holders and allow for the holders to be fitted at various heights nd distances along the Y axis.

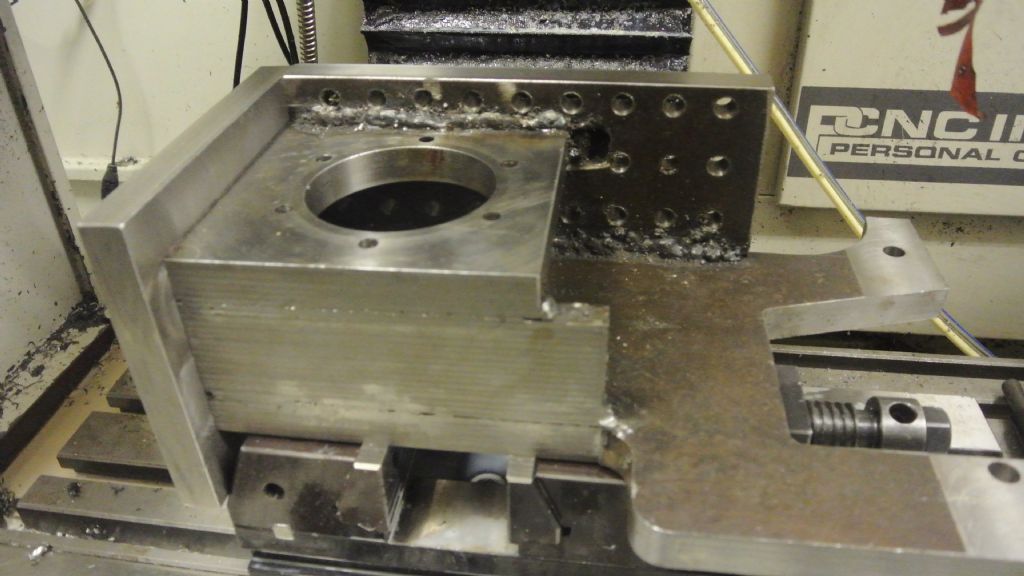

This view shows the front plate of the fixture, the large tapped hole is there to take the securing bolt from my Quick change Tool post on my BH 600 lathe that I have at least 10 holders.

This view shows the two rear holes in the lower plate. A spacer is fitted on top of the machined portion of this plate before the screws are passed through from beneath and screwed into the travelling head.

This view shows the two rear holes in the lower plate. A spacer is fitted on top of the machined portion of this plate before the screws are passed through from beneath and screwed into the travelling head.

It's been an interesting project so far. I have started making some tool holders which will be able to take the small size Quick change tools that I bought for the original attachment, these will be height adjustable so I should be able to set them at the same height. They will also be bored to take round shanked tooling such as boring bars and the Tormach modular tooling that have a 3/4" shank dia.

Once I get some of the toolholders finished I will set up the lathe on the mill and take some shots of it and maybe some video of it in action.

Another JohnS.