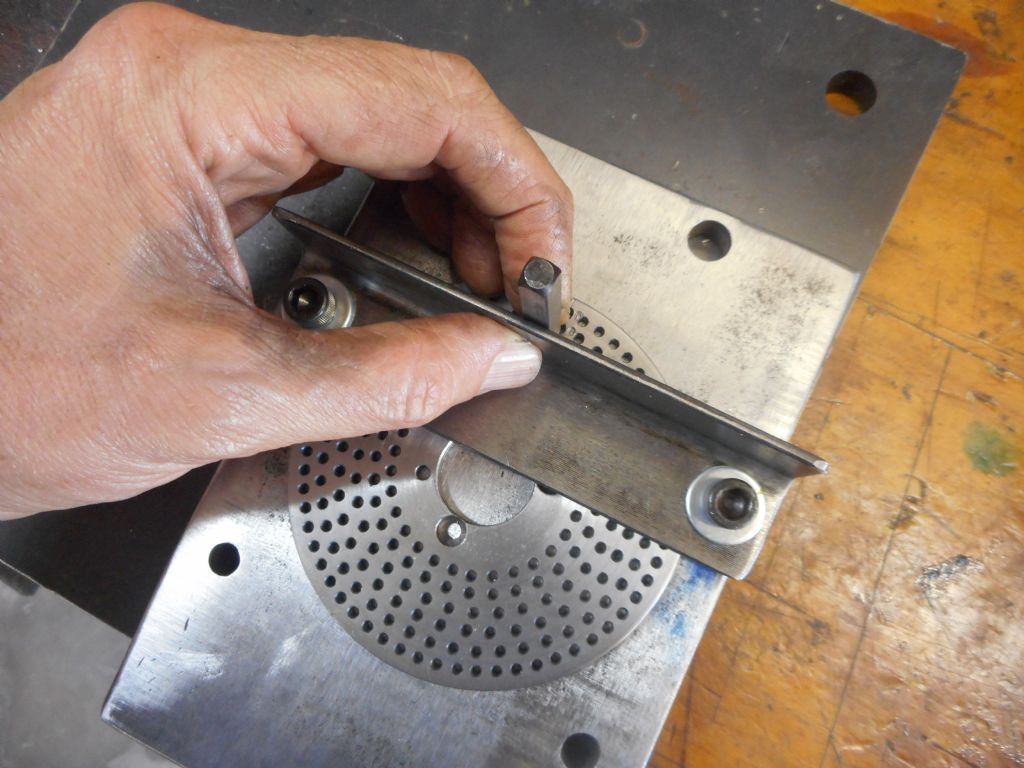

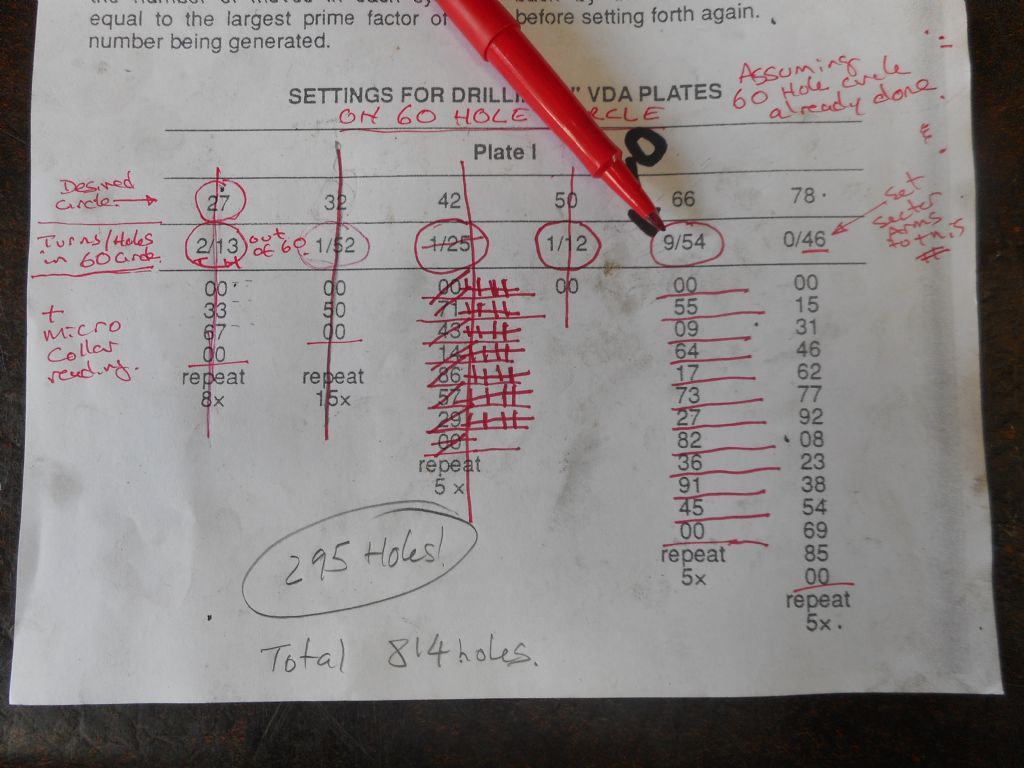

Drilling drilling drilling. My hour in the shed today was an interesting one. I found an error in GH Thomas's charts for drilling the holes in the Versatile Dividing Head index plates. I couldn't believe it, but did the math myself and confirmed the chart showing how many turns of the handle, spaces and increments on the micro adjuster contains a major error. Where he specifiesfor the 66 hole circle, 9 turns of the handle, plus 54 holes, plus 54 divisions on the micro adjust it should read 0 turns of the handle, then move 54 holes and 54 divisions. A simple typo but it nearly had me fooled into blindly following it, thinking it must be some special advanced technique requiring multiple rotattions of teh job to achieve the 66 holes via a number of stages. But doing the math revealed that the seventh hole done this way would partially overlap the first hole , and just get worse from there. So double checking the math, 0 turns rather than 9 turned out to be right.

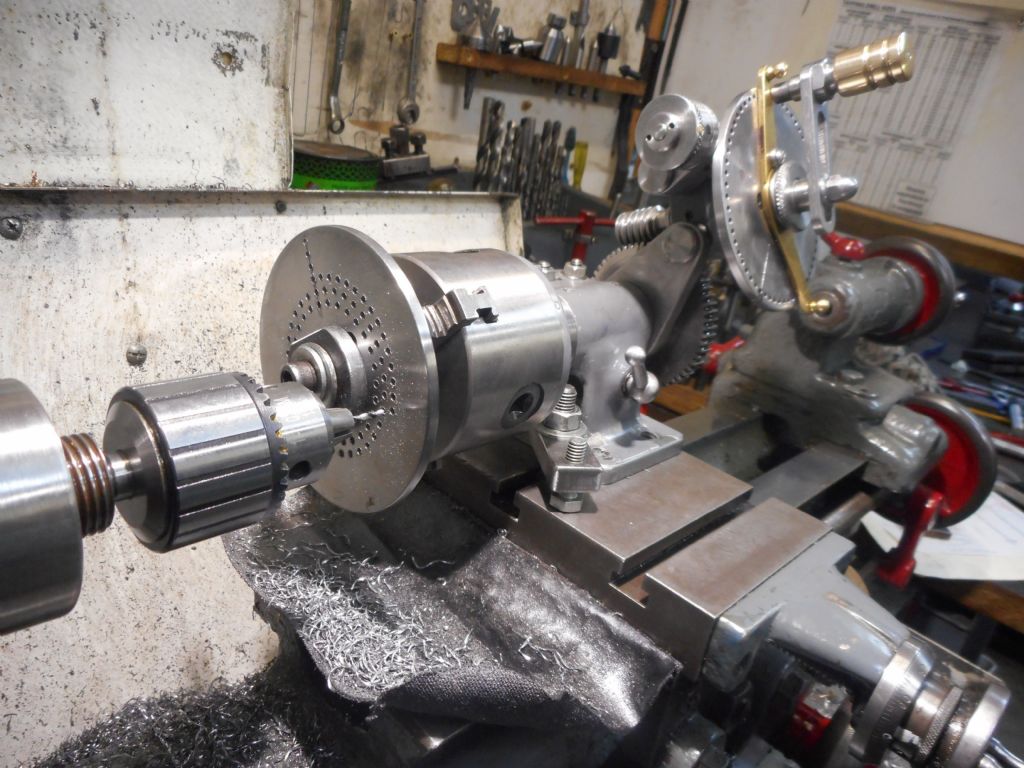

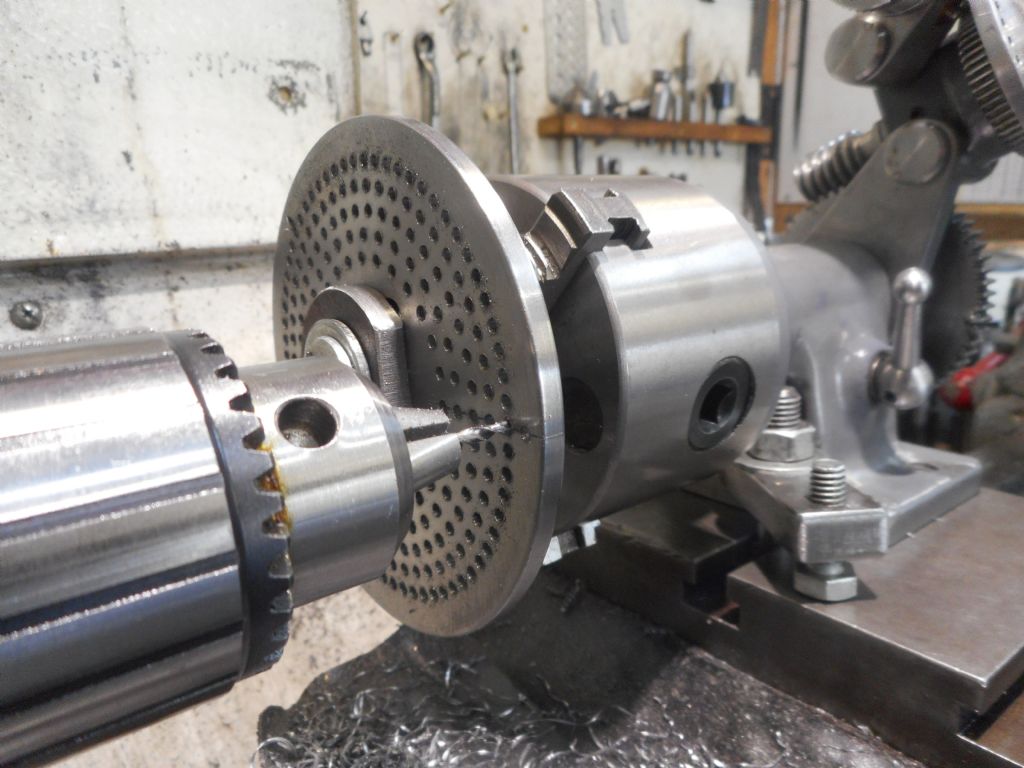

Nonetheless, it was with some relief that the drill dropped straight into the first hole after completion of the circle and returning the indexing arm and micro dial to the 00 setting. Whew!

Had a self-inclicted snafu along the way. Started cranking the index handle without withdrawing the drill bit from the job. SNAP! One drill bit gone. Lucky I have a small box of these 3/32" stub drills, shipped especialy from UK to here in Oz. BUT, the next bit snapped in half while drilling the first hole after fitting it up. Under power feed, so it managed to friction weld a small piece of HSS into the bottom of the half-drilled hole. Which also destroyed the next drill I tried, very optimistically, to finish the hole with. So when all else is finished, I shall have to turn the disc around, index off the adjacent hole and drill through from the other side until I hit the embedded HSS and then punch it out if I have too.

Never a dull moment while drilling these 814 holes! Just over 300 to go now. I can hardly wait.

Edited By Hopper on 28/08/2017 10:41:42

Another JohnS.