I'll try and answer all the questions, albeit it with some duplication of the excellent information posted by Nigel.

The horizontal mill is indeed an Adcock and Shipley model 2E. It is universal, meaning that the table can swivel for spiral milling, not the common myth that a 'universal' mill is one that can be configured as horizontal or vertical.

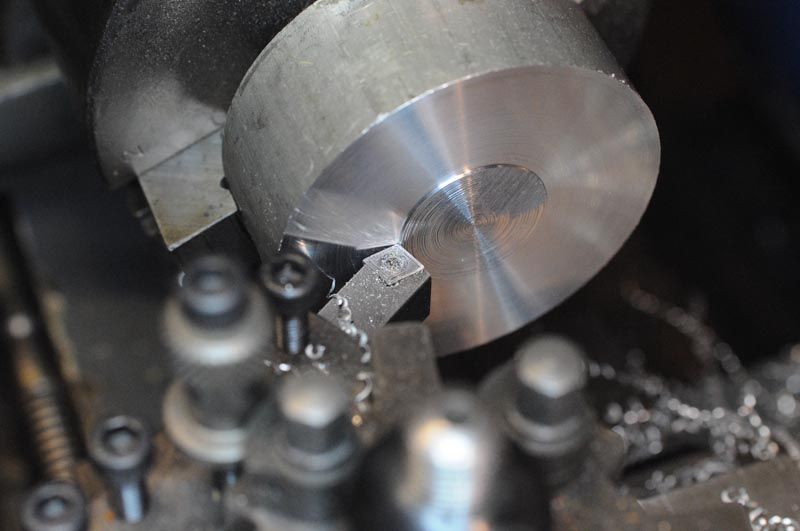

The table feed in on X only. The feed motor is on the knee and drives through gears into a gearbox with two selectors for a total of 18 feedrates:

Drive to the table is via two skew gears, able to cope with the table being swivelled. The table does have a backlash adjuster, which basically rotates a second feed nut on the leadscrew. However, it seems a bit loose to me, so I haven't had the nerve to try it. I can't remember if the table feed motor is 1 or 1.5hp.

I'm a bit puzzled by the 2/3 ratio for low and high feedrates. The main drive motor has a low and high range, in the ratio of exactly 2 to 1, as would be expected by doubling the number of poles. The main motor also switches from star to delta in low range so the loss of power is not a great as might be expected from a halving of angular velocity. The feed motor doesn't appear on my schematic, but I assume it is completely separate electrically from the main drive motor. May be it's some sort of odd 4/6 pole motor?

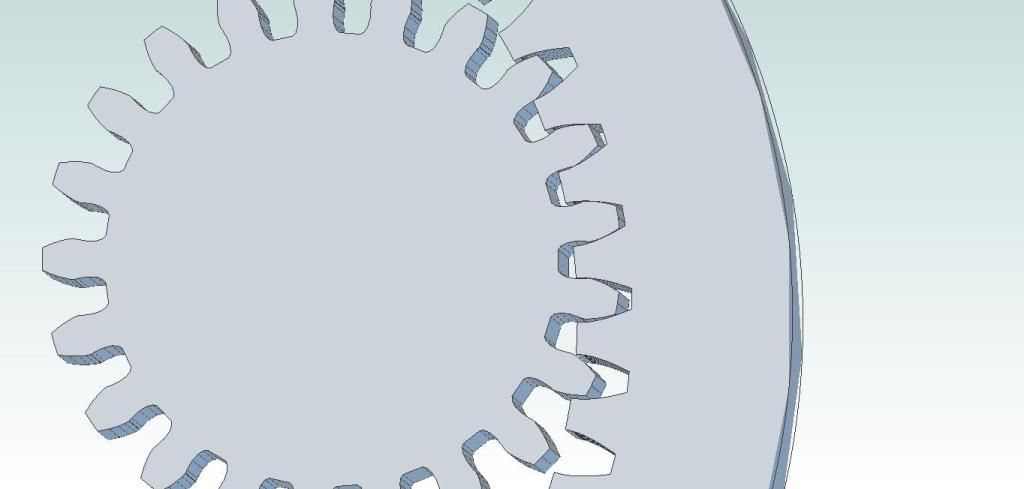

As Nigel has pointed out the Bridgeport can be used to cut helical gears, even though the table does not swivel. Presumably with a right angle attachment and support one could also swivel the ram and cut in 'horizontal' mode. My primary reason for wanting to use the Bridgeport is to cut high helix angle gears. In theory the table on the horizontal mill can be swivelled ±45º, but I'm struggling a bit with clearances and access with it set up for a 30º LH helical gear. I have a vertical head for the horizontal mill but not the universal head mentioned by Nigel. I've never seen one, or ever seen one for sale, so I suspect they're in rocking horse sh*t territory. However, I do have a right angle attachment for the Bridgeport which can be swivelled to achieve much the same, albeit with less rigidity.

Of course the problem with driving the dividing head by the method shown for low leads is that the gear train from the table has to step up to compensate for the worm reduction. This can lead (pun intended) to large loads on the gears. The manual for my dividing head talks about a low lead accessory, which uses the gear train to drive the dividing head spindle directly. It's a pretty simple device, just a plate with slots (like the existing banjo) and an expanding shaft that fits into the DH spindle. I may well end up making one. However, to use it you have to disengage the worm, so you can't index the head.  So it would be fine for milling worms or threads, but no use for gears.

So it would be fine for milling worms or threads, but no use for gears.

The manual also talks about turning the division plate and using that to drive the table instead of vice versa. Of course this means that the gear train then becomes reducing. I had a quick play with this last night. I think I know how it works, but once I've made the mating LH helical gear I'll break down the set up and experiment in more detail.

Darn it, rather than leaving the question of spiral milling on the Bridgeport as a theoretical concept I can see that I'm going to have to try cutting a high helix gear on it, just to satisfy myself that I can do it.

Another mystery solved. On the dividing head, when indexing if the plunger isn't fully retracted it is possible to 'pickup' the fingers, which rather badgers the indexing. The indexing spring is quite strong and I could foresee I am going to struggle with the limited access. I wondered why the manufacturer didn't add an indent so the plunger could be turned without have to pull against the spring. Then I wondered why there was loose collar on the indexer. Turns out it's the locking indent, except that it's missing the small spigot needed to lock the indexer in the out position. I've found a suitable bit of silver steel, so this evenings job will be to fit it.

And as an aside to those who might be thinking bl00dy cheque book engineers and their toys, the total cost of the horizontal mill and dividing head was about £500; less than yer average benchtop mill.

Andrew

JasonB.

JasonB.