Hi, yesterday evening while using my Boxford lathe I had on occasions, moved the backgear lever into a neutral position to enable me to turn the mandrel by hand. I had no problem with doing this, but several times I restarted the lathe and forgetting to re-engage the gear beforehand. Ever since I've had this lathe the motor would start with the lever in the neutral position, but I normally re-engage the gear before starting the motor. In the "Know Your Lathe" manual it clearly states that undoing the socket head screw that locks the backgear lever in position, cuts the power to the motor and the delay caused by undoing the screw completely, ensures the lathe comes to rest before the lever can be moved, thus preventing damage to the gears, so given the amount of times that I restarted the motor without putting it back into gear, prompted me to investigate the problem. Removing the micro-switch which is housed on a cover plate in a hollow just below the backgear lever, it was found that the button of the switch was jammed in. Disconnecting the switch to get a better look, it was found the cause of the button being jammed in was due to the hole in the plastic cover being depressed and burred over the top edge of the button. I cut the offending plastic burr away with a Swan Morton Unitool knife and filed the depression off around the button hole on the plastic cover and then washed all the debris out with switch cleaner to get the button moving freely again.

This evening I refitted the micro-switch to the lathe and screwed in one of the socket head screws that hold the backgear lever in position until I heard it click, screwing it in a little further, I could feel it bottom out, but the lever itself was not quite nipped fully home, however the motor started and stopped as it should, so I tried the other screw in and this one nipped the lever fully home, but the motor would not start. Removing the screws revelled that one screw was longer than the other and I further concluded that the longer one was to long and caused the button to be jammed in, in the fist place.

I decided to replace both screws with new ones, but I didn't like the idea of the plain part which allows the screws to hang loose in their holes. This I've always found a nuisance, as you have to lift them up to get the lever across each way. I found a couple of long screws with knurled heads that I'd salvaged from some scrapped electronic motor control gear years ago.

I made an accurate measurement of exactly how long the screws with a fully depressed spring and a washer needed to be and cut them off and fitted them into the lever.

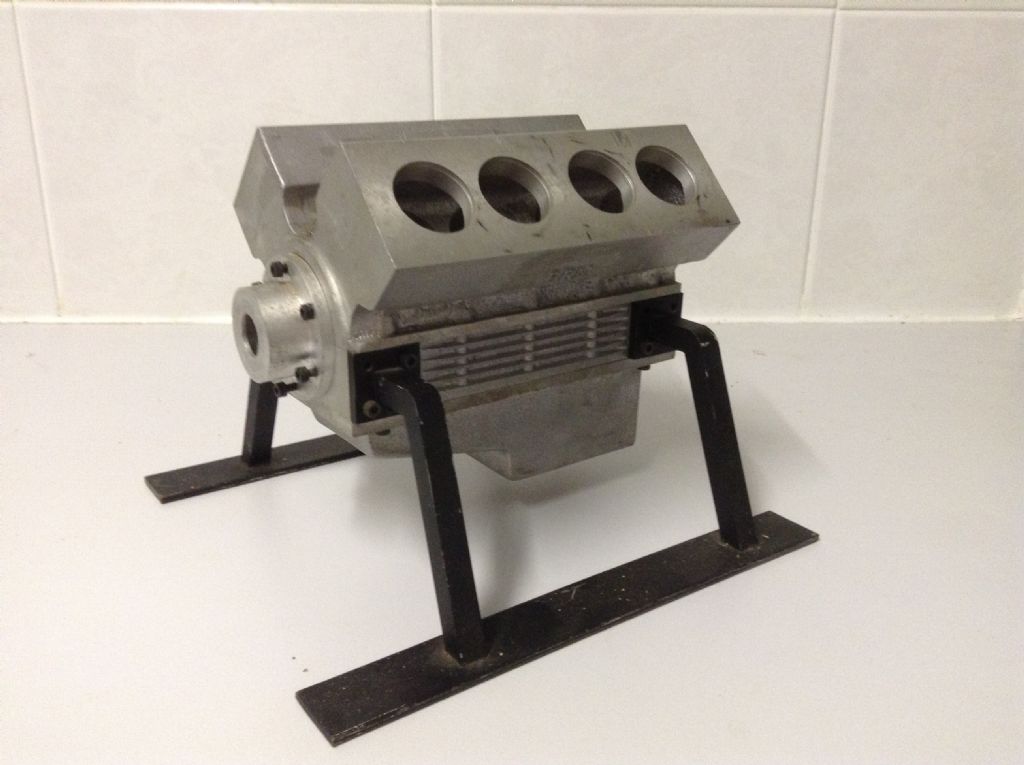

Happy to say that both the screws are now working correctly and I shouldn't be able to start the motor anymore while the lever is in the neutral position and thus avoiding any damage to the gears. The idea of the springs is to stop the screws from vibrating in or out when they are not holding the lever down, time will tell if it works. In the photo above, can be seen the plate that holds the micro-switch in the hollow below the lever.

Regards Nick.

Edited By Nicholas Farr on 12/07/2016 23:18:35

JasonB.

JasonB.