Rainwater into carport saga:

I think I may have found the cause of water ingress from the bottom of the Up&Over door, but need to wait for the next downpour to be certain before details and photos. Also don't want to be tempting fate.

Tom Senior:

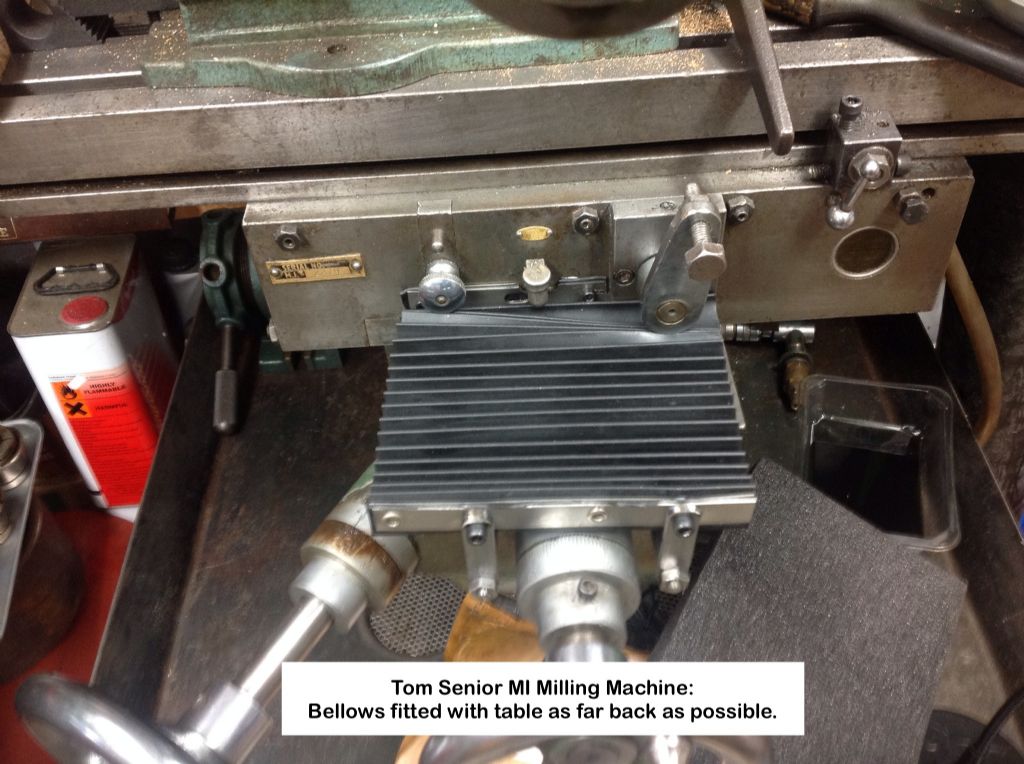

Fitted the Machine Bellows to cover the front Way, plus put the original rear Way cover back, and now have protection for the Leadscrew, whereas before there was none.

For the front, did think of using some 1/4BSW threaded rod I had, but gave myself a slap for even thinking of using it, so made two stand-off studs from hex bar for uprights to be fitted at the ends that would hold the Machine Bellows.

It's worked out pretty well, even though I say so myself. More photos in Album.

I'm going to try a 6" handwheel on the Y-axis, in place of the present 5", as it needs a bit more leverage due to either the nut of screw having been graunched at some time and not easy to turn, and not easy to turn as it should be.

Way protection for the Marlow Mill next

Geoff – It's raining!

Edited By OuBallie on 16/11/2014 15:22:24

Edited By OuBallie on 16/11/2014 15:23:25

John Haine.