Posted by Chris TickTock on 25/08/2019 13:57:34:

OK More detail but not sure I haven't given enough already…

…

Chris

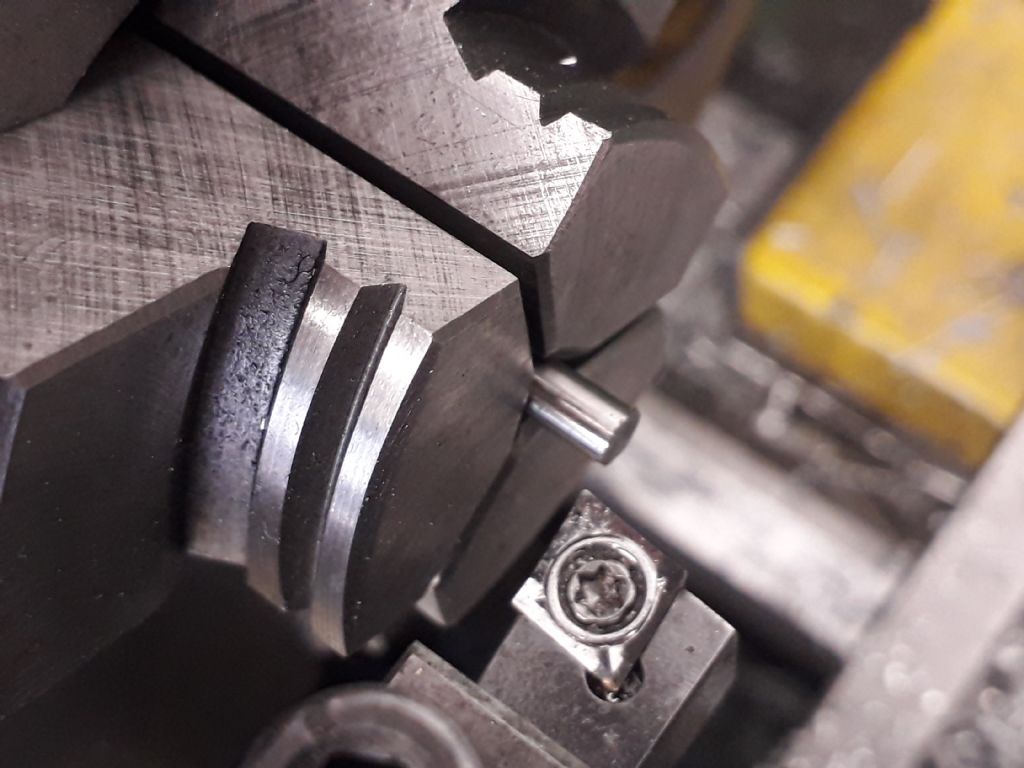

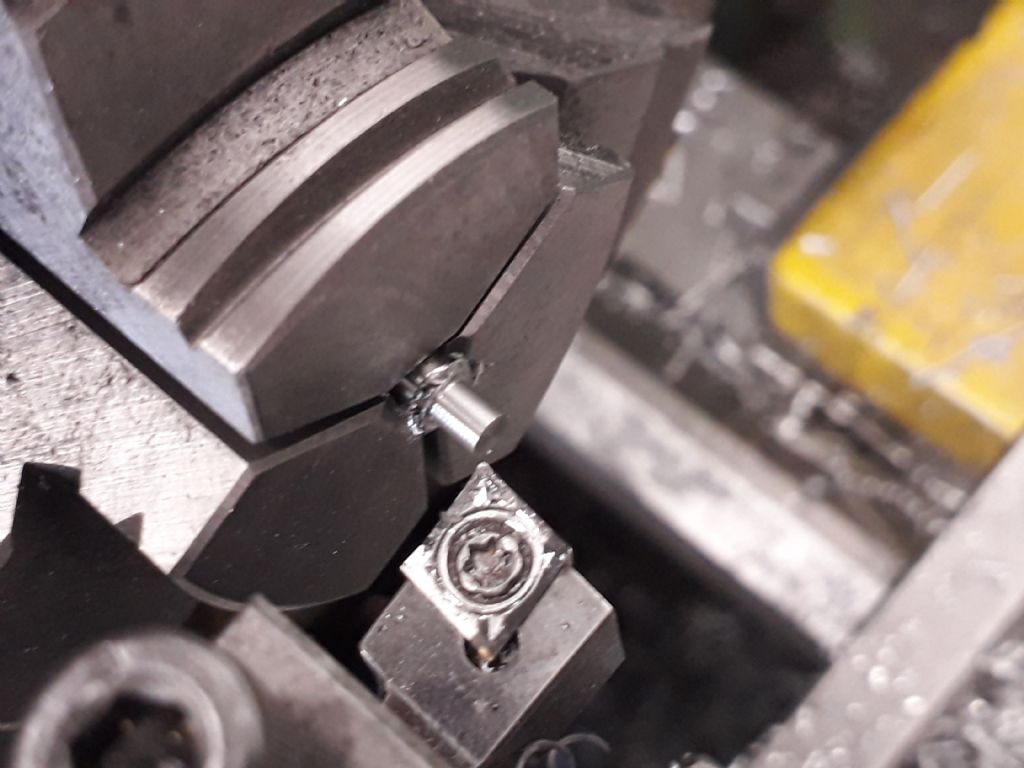

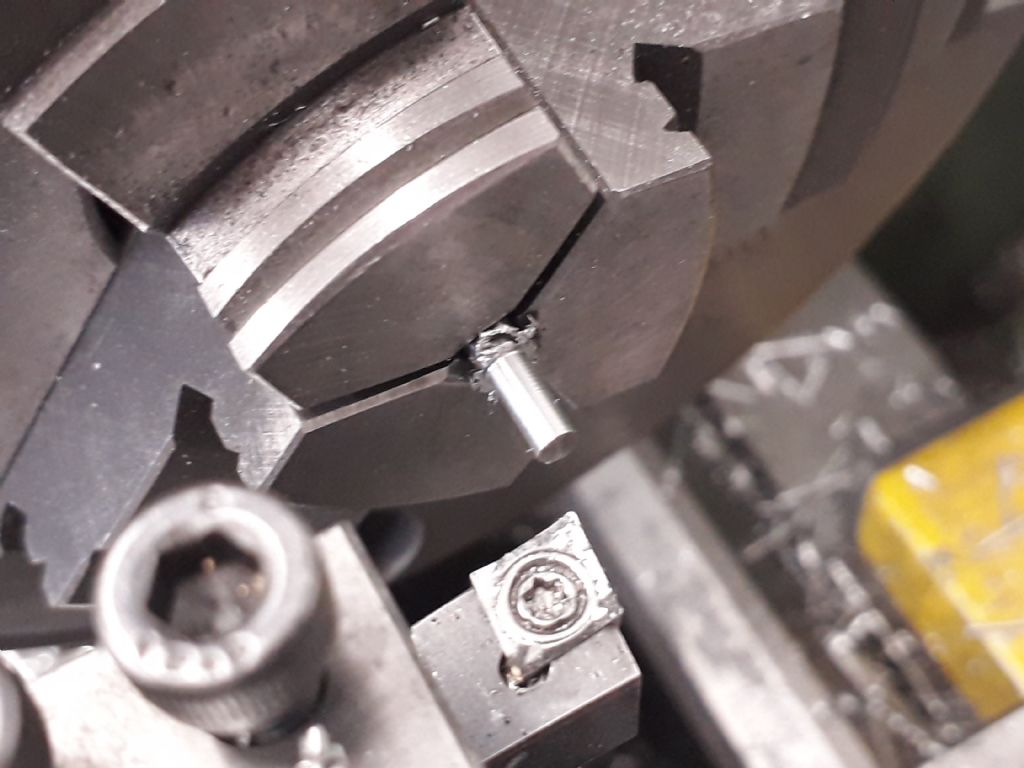

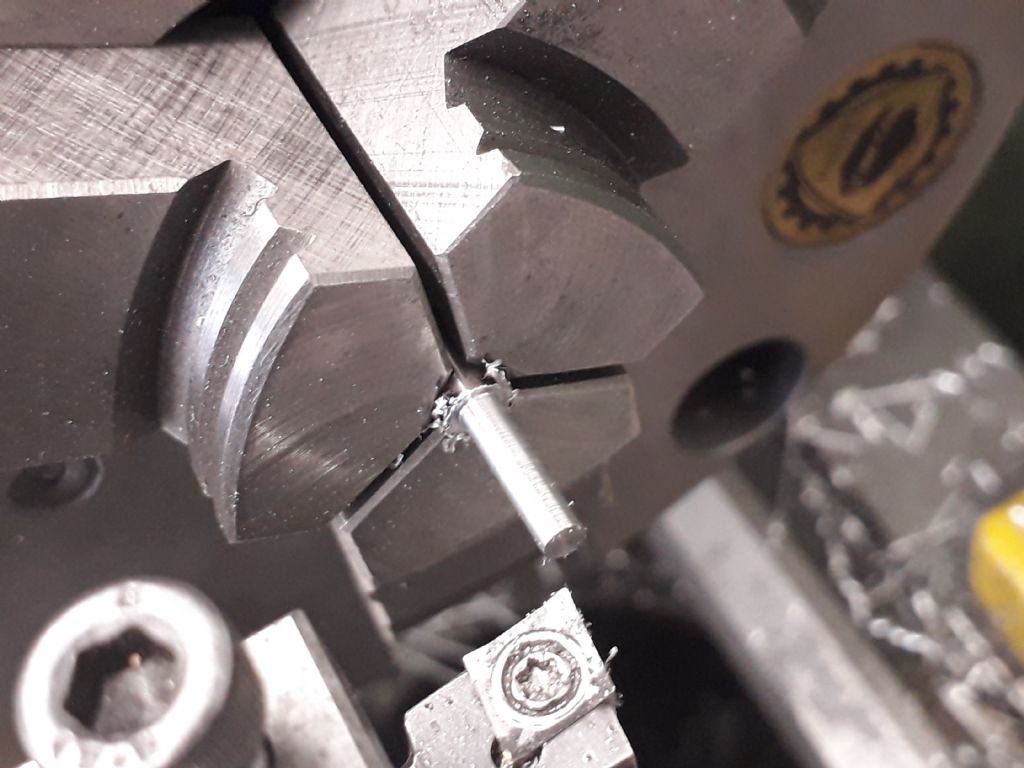

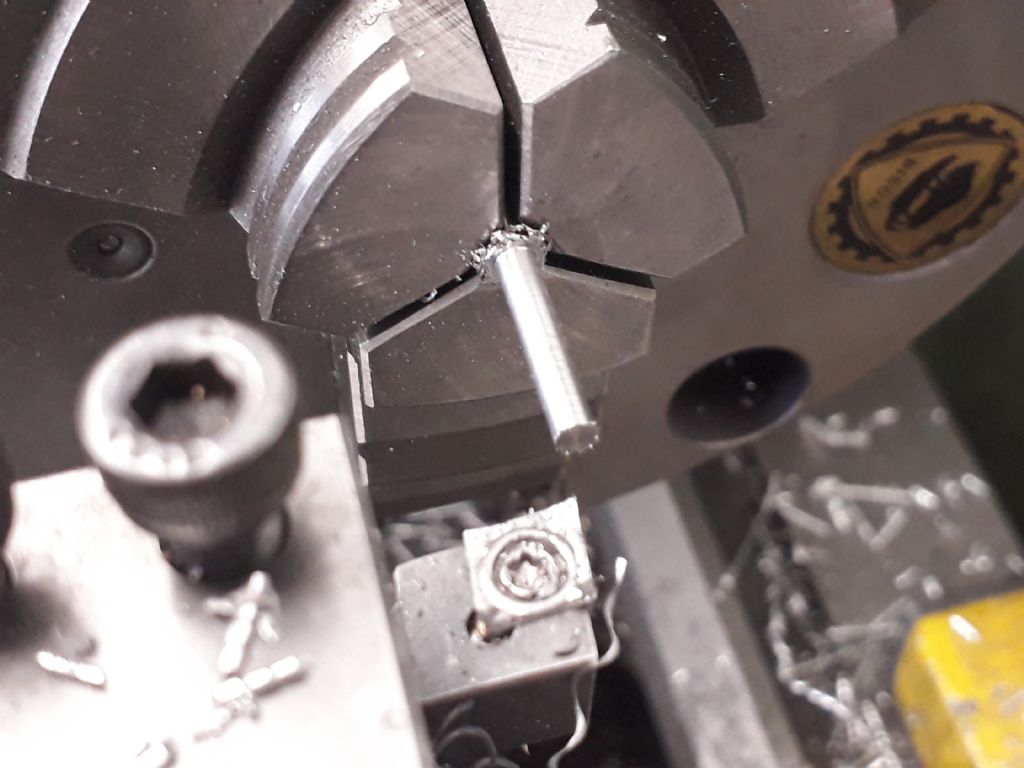

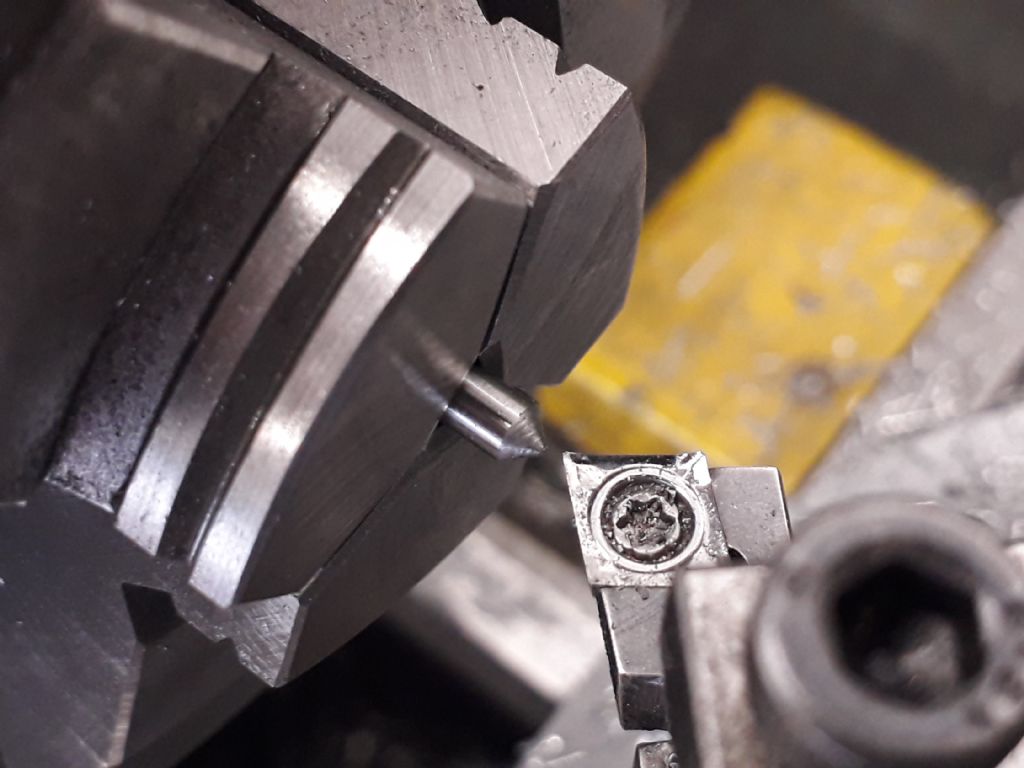

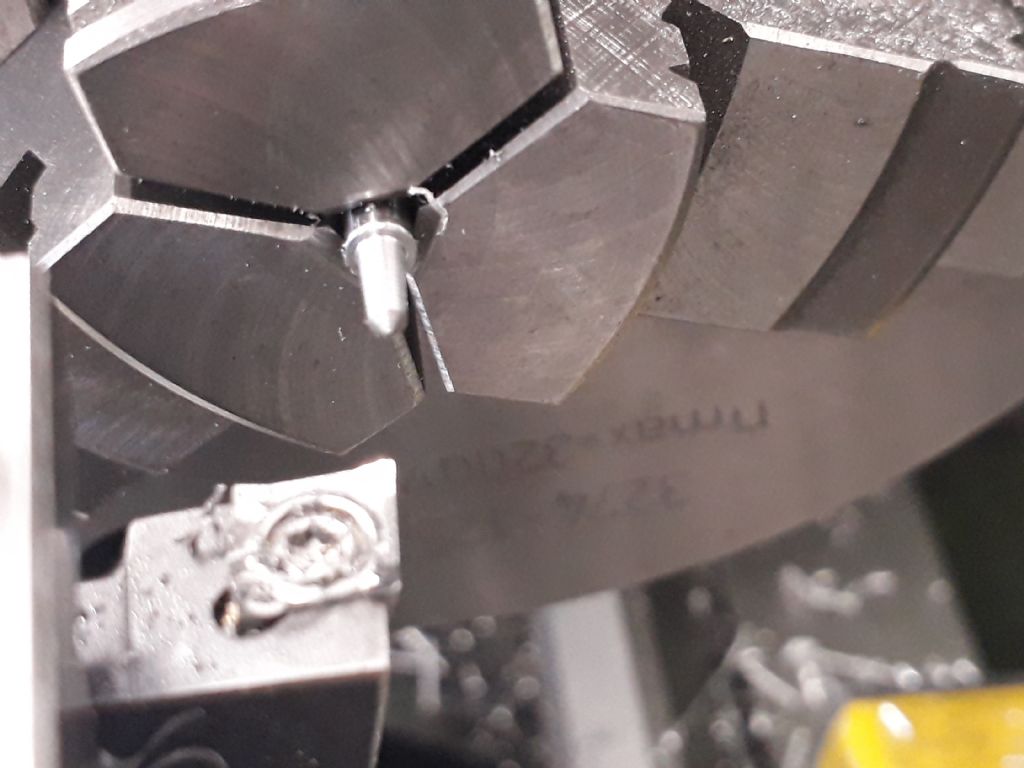

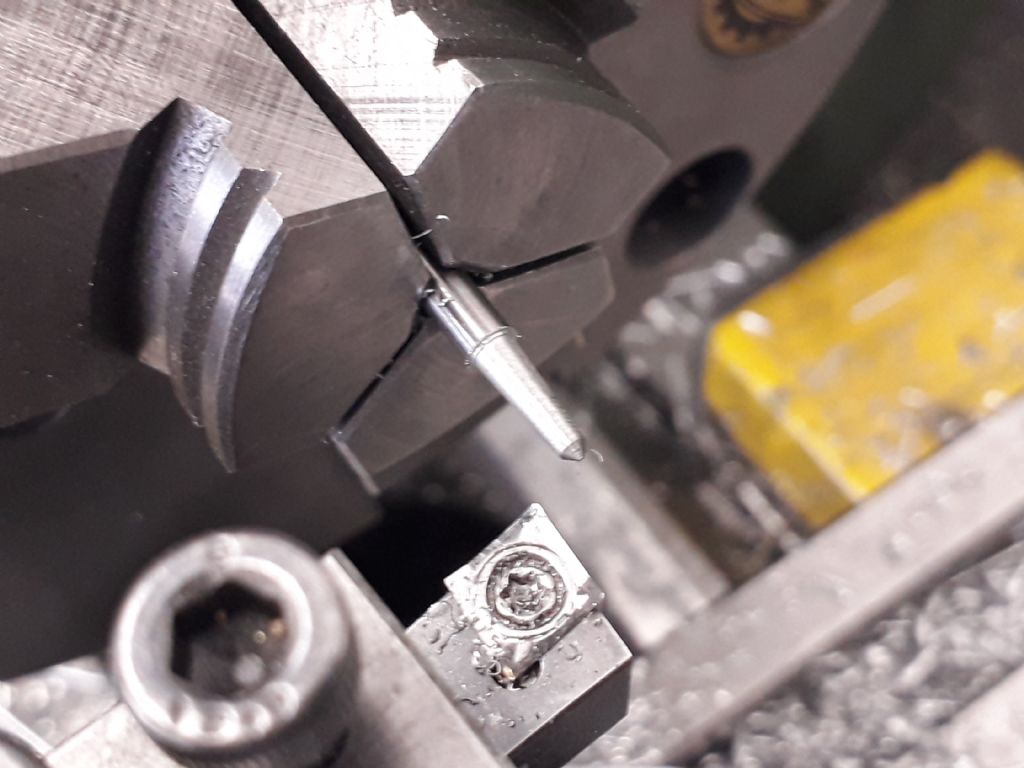

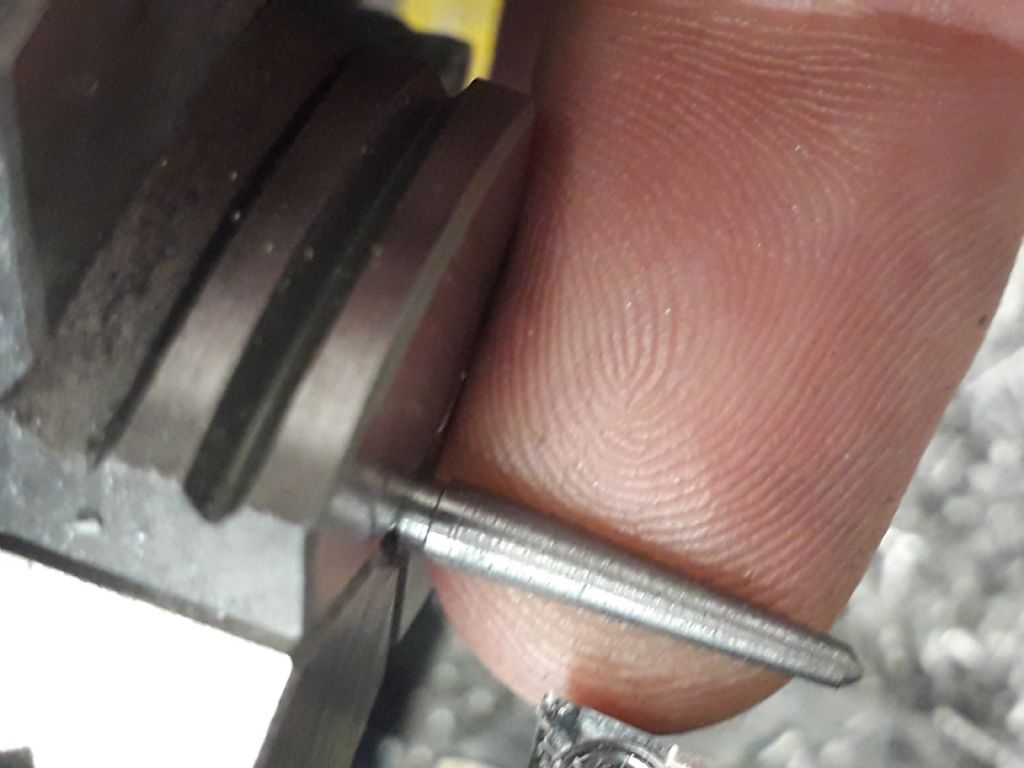

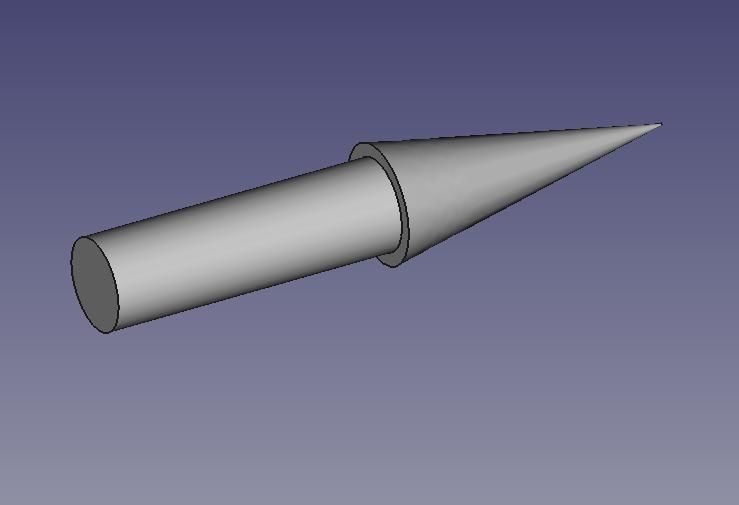

Don't worry Chris, engineers like to have all the details. Long painful experience has taught us that even carefully drawn and double-checked drawings can mislead. As we haven't read your project book and don't have access what's in your mind's eye it's really easy for chaps to get confused and give misleading answers! A picture is worth a thousand words; I reckon you mean one of these:

This object's a difficult challenge because long thin rods bend easily. You have to plan how the rod will be supported whilst being cut to shape : it's not as simple as gripping one end in a chuck and shouting 'tally-ho'. At least on a Sherline there's no risk of the rod kinking and whipping into the operator at high-speed. Many nasty accidents on big machines where several horse-power at high rpm can instantly convert a long steel rod into a lethal flail.

The answer is to plan some way of supporting the job during the cut. A fixed or travelling steady will be too big. Bob's suggestion of making a female centre is a good one. The idea is to put a short section of taper on one end whilst most of the rod is safely held by the chuck, then to extend the job out so the point runs in a female centre held by the tail-stock. A rod supported at both ends is much stiffer. Still needs a sharp HSS tool running at high rpm exactly at centre height (See Howard.)

Another method might be to support the rod with a block of wood opposite to the cutting edge.

Planning is an important skill because the order of operations can make life easy or impossible. I often rehearse various methods and sleep on ideas to make sure they're sound before trying it. Being self-taught is a disadvantage; apprentices get told stuff and lots of on-the-job training. The rest of us bumble about! A good trick is to delay cutting objects to final size for as long as possible because the base stock can often be used for gripping and support during manufacture. In other words don't start by cutting 1.25" of silver-steel off and then struggling to hold a small bit of metal. For the same reason, finishing the taper should be left late because a taper is much harder to hold than a cylinder. Also, avoid weakening the job until the last moment.

As Neil suggests, a good plan should look for ways for simplifying the job, in this example avoiding turning down to 2.5mm by drilling a 1/8" hole instead. Don't do that – at this stage of the game it's more useful to learn how to make the difficult object. Cheating comes later in the curriculum!

Dave

PS Must learn to type faster. Jason made one and posted photos while I was dithering. My work-rate is depressing…

Edited By SillyOldDuffer on 25/08/2019 15:29:14

JasonB.

JasonB.