Posted by John Stevenson 26/10/2016 23:20:51

"Clive asks about a CNC version but Alan ? Pace did one in MEW that

just sharpened the flutes and glossed over doing the ends."

Yes he is right ,the reasons why the ends were not included is because

the machine uses the Quorn workhead and as such the ends can be

sharpened on the Quorn.The ends could be done on the cnc machine

but would it be really worth the effort to write an additional part to a file to

do it.

I don't think that some have grasped the difference of the type of

cnc machines that are used for the production of new cutters and

requirements of a similar machine in a model engineers shed.

A machine making new cutters picking up blanks ,loading and then

grinding them all over and them returning them to the tray is somewhat

different to rummaging around in an ice cream box to find an old

cutter and returning it to a new cutting condition ,i do this all of the time.

The article for this machine was published in 2008 ,i had hoped that

it may have given others some insipiration to work on something

similar ,instead you see the same old methods used , here is an

example from one such.

"The clearance is set by tilting the table down on the right but just

setting this to the required angle is no guarantee that the clearance

angle on the cutter will be correct. For this the cutter must also be

set as shown in Sk. 8. If, having sharpened the spiral cutting

edges, the cutter fails to cut as you would like, almost certainly

the clearance angle is insufficient. For smaller cutters you may

need to provide secondary clearance."

Oh dear not very good is it.

An excerpt taken from the text of a well known cutter grinding attachment.

It is worth pointing out that the cnc machine has a resolution of 1 /20 th

of a degree and as such the clearance angles can be set as such

and yes it is verifiable.

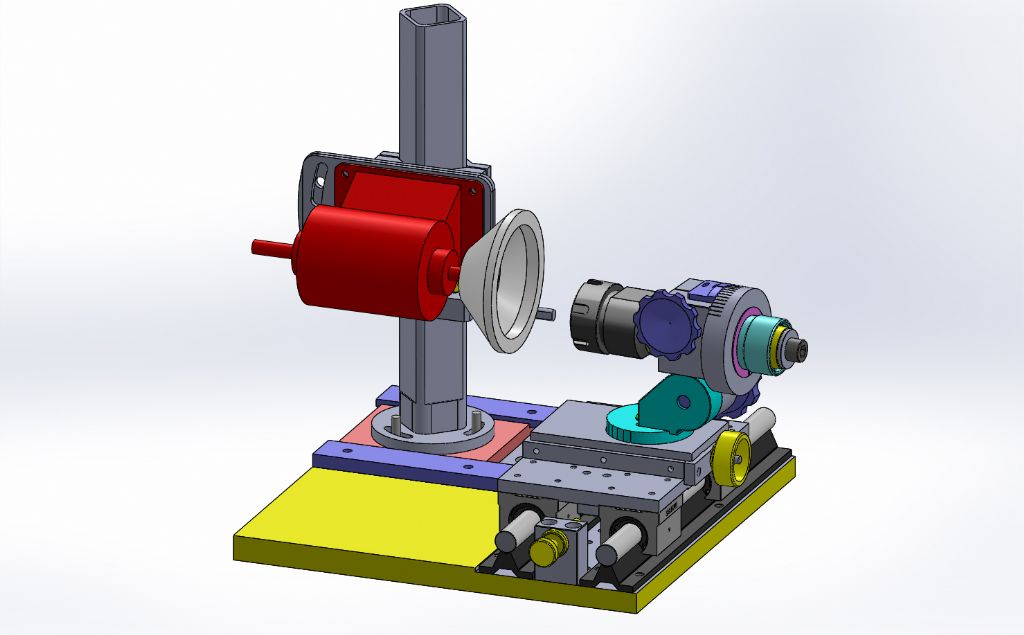

I feel that this not bad for a machine made mostly from scrap material,

the main base is from two pieces of channel steel welded together.

Photo's in album "Quorn an cnc grinder".

It works similar to the demonstration in this video.

http://www.youtube.com/watch?v=qxU0K-TmEvI

Obviously this machine has a much better operating system to be able to do this ,

something that would be unlikely to be seen in the home workshop and i expect

beyond home workshop budgets.

Getting back to th OP's original question ,I suppose it really depends on whether

you are just out of your pram or a coffin dodger.

I built my Quorn around 1985 or so i think it was about £350 a lot of money then,

Divide that by the thirty odd years that i have used it = £11 .66 and all of the cutters

and other jobs that have been done over that time ,seems like a good deal to me.

John

John Stevenson 1.