Wabeco lathes are unconventional in using toothed belts and pulleys for the change gears. This works well but I found some errors in the change gear table in the handbook for my Wabeco D4000 lathe. Some combinations of belts and pulleys would not fit – easily solved by buying a different length belt (they are standard XL belts, so readily available and inexpensive), but it led me to wonder whether the pulley and belt combinations in the table were optimum.

I realised that in many cases there are other combinations of wheels and belts giving the same overall ratios. Some combinations fit better or have other advantages, e.g. a larger final wheel reduces the effects of inaccuracies such as eccentricity of the wheel or tooth pitch variations in the belt. The larger wheel also reduces the load on the belt due to the torque needed to turn the leadscrew.

Checking whether certain combinations would fit proved tedious so I decided to put together a spreadsheet that takes into account the geometry of the effective diameter of the toothed wheels, the belt lengths and the positions of the wheel arbors on the change gear quadrant, to calculate whether a chosen combination would fit.

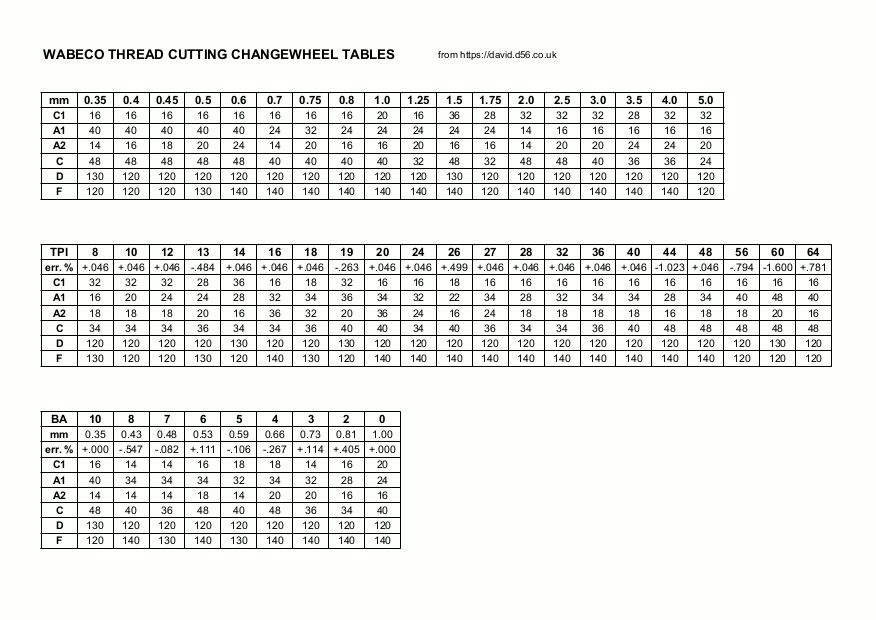

The tables below have been validated using this spreadsheet. They are somewhat expanded on the Wabeco ones to cover the standard metric fastener pitches from M1.6 up, plus a comprehensive range of Imperial and BA threads. Only the standard set of wheels are used but the table assumes a 130 belt is available in addition to the supplied 2x 120 and 140.

The tables apply to the D4000 lathe. They may apply to its bigger brother the D6000, but I don't know whether the change gear geometry is the same.

Because the lathe has a metric leadscrew, the Imperial and BA threads have a small pitch error as shown in the tables. For some threads where the error is relatively larger e.g. 60TPI, this may or may not be significant depending on the application.

A printable pdf version can be downloaded from my website.

Hope someone finds this useful.

David

gerry madden.