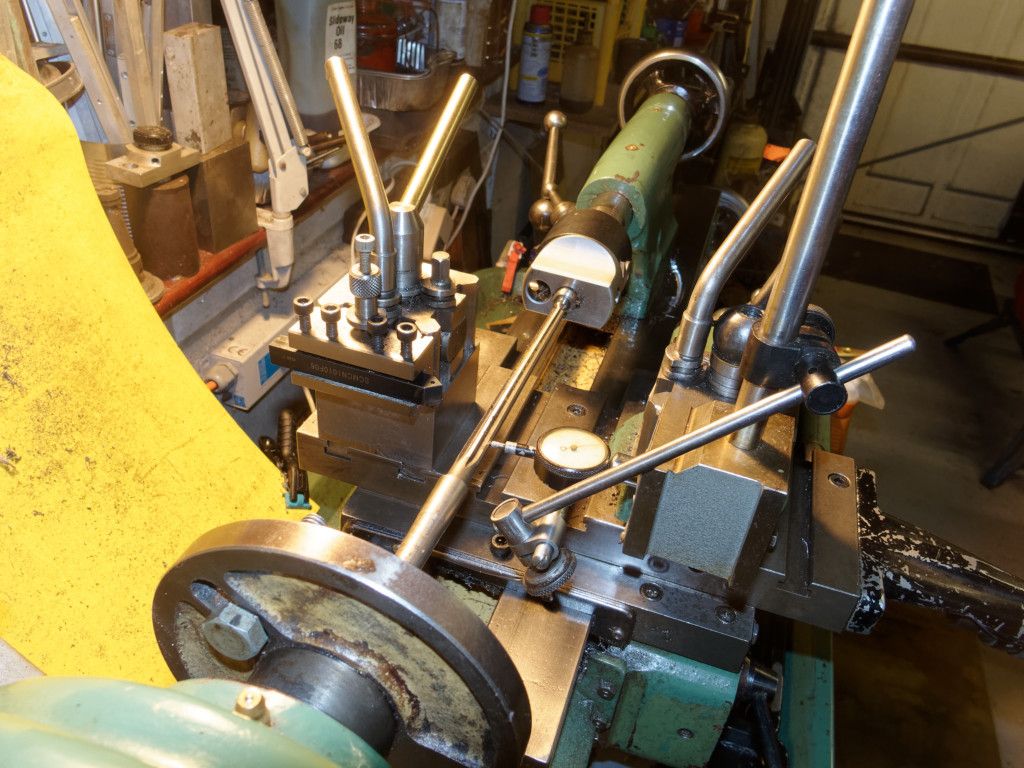

George, If you have a boring head, have a look at the two photos below before you disturb your tailstock setting.

The idea is that you can easily dial in a chosen offset using the sliding part of the boring head.

In my case I made the boring head centre using a broken solid carbide centre drill.

I had a need to make a taper pin for a newly acquired shaper, so clocked in the correct offset using the actual taper pin reamer that I was planning on utilising to re-ream the clapper toolpost.

Note Imperial reamers are 1:48 taper, whereas Metric are 1:50

The one thing you must remember, in a case like this, is that the workpiece must be exactly the same length as the taper you are trying to reproduce; centre to centre. In my case that was way too long for the pin required, so I just turned the workpiece round and made a spare.

The photos below are a quick lash-up I've just done to illustrate the principles for this post. At the time, I had a clock set up more rigidly in the front toolpost.

There are ready made devices available for this type of offset turning, but why shell out if you already own a boring head.

Grinding the carbide centre (ex-drill) was a bit of a lash-up too.

No photos for that one as it was in a previous workshop, where the Clarkson Tool and Cutter grinder was (too) near the lathe. A flexible shaft held in the lathe chuck bent through 90° to the T+C grinder and spun the centre whilst the grinder shaped the cone on the end.

Bill

Edited By peak4 on 29/10/2018 19:58:48

Hopper.