Happy Christmas and New Year to you all and thanks again for all the advice..

Day 43. ( This was too long to put in one post so have had to split..)

The Piston and Piston Rod.

Haven't done a brilliant job again with this but have learnt quite a bit I think, which was great…..

The main 'mistake' was not having any material to make a split bush with which to hold the Piston Rod (various sizes of bar 'stock' material now been added to my ever growing shopping list..). I think this was essential really and would have been simple and quick to make…. The result in not having the bush was that the Rod was easily marked in the chuck, despite holding lightly and soon losing the 'ground' finish – all not good for future wearing etc.. The other was not quite getting the 'packing groove' to correct width and having to remove the 'O' Ring and resize, not easy without damaging it…

It all seems to slide and fit ok though, although the rubber 'O' Ring seems to stick slightly sometimes, I guess making steel piston rings would have been too advanced….

The Piston assembly Drawing.

The material supplied for the Piston and Piston Rod. Stainless Steel for the Rod and Cast Iron for the Piston.

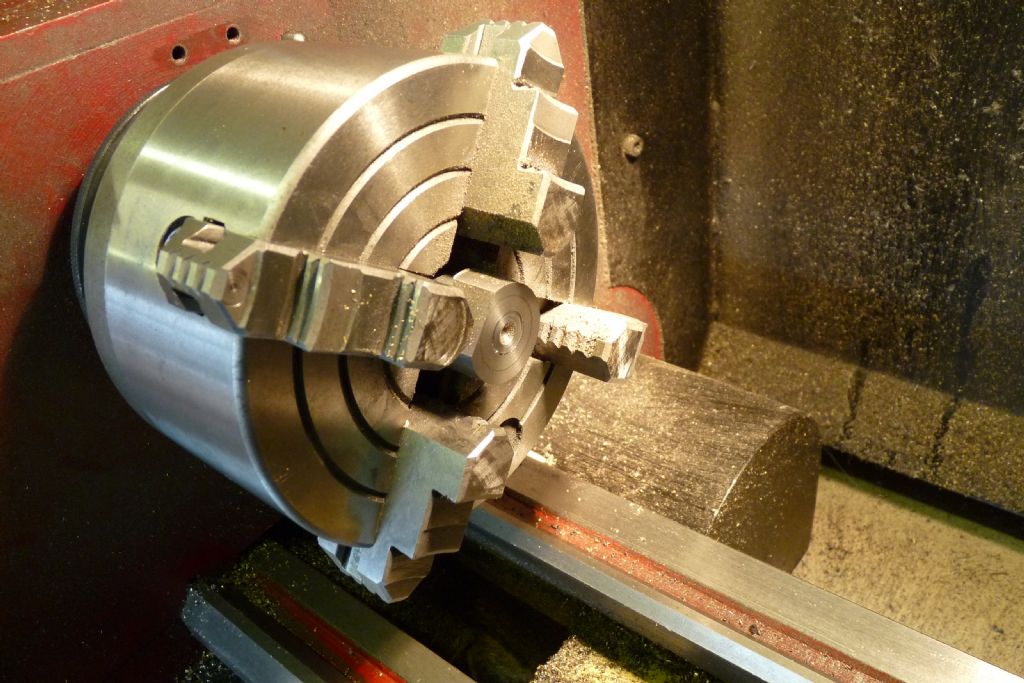

Turning the Piston end of the Rod for threading 5BA.

Threading the Piston Rod 5BA.

Half of the Turned length was threaded with the 5BA thread.

One end of the Piston Rod done.

The 'Crosshead' end of the Piston Rod was threaded 2BA in the same way as above.

After facing, the piston was lightly centre drilled and turned to about 1/32 oversize.

A parting tool was used to do the 'Packing Groove'.

continued…

Edited By Allan. on 23/12/2013 18:40:33

GarryC.