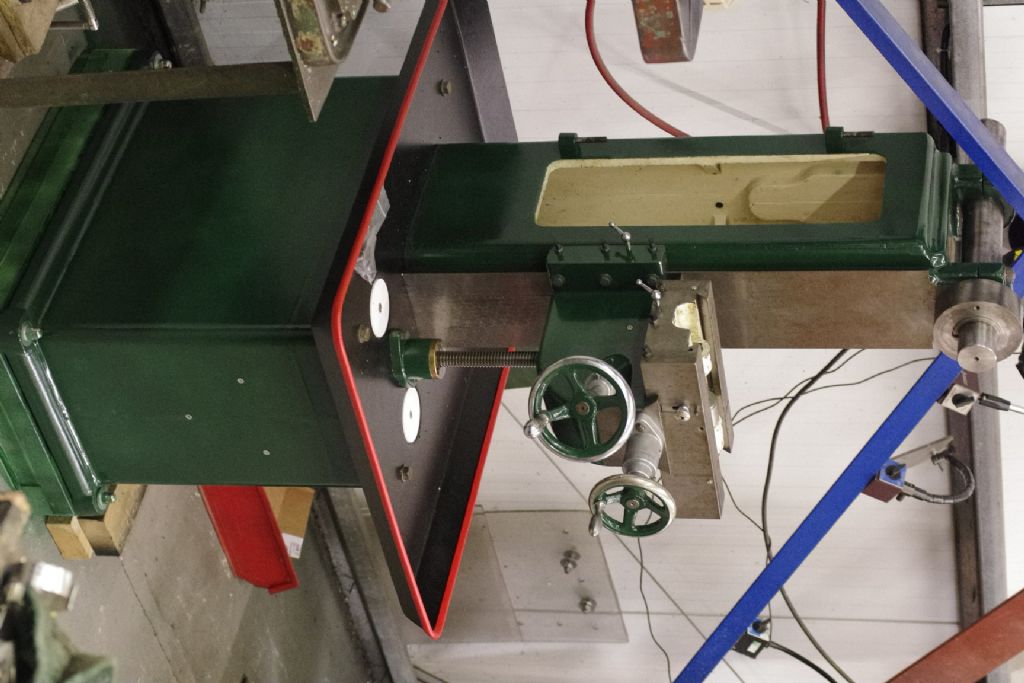

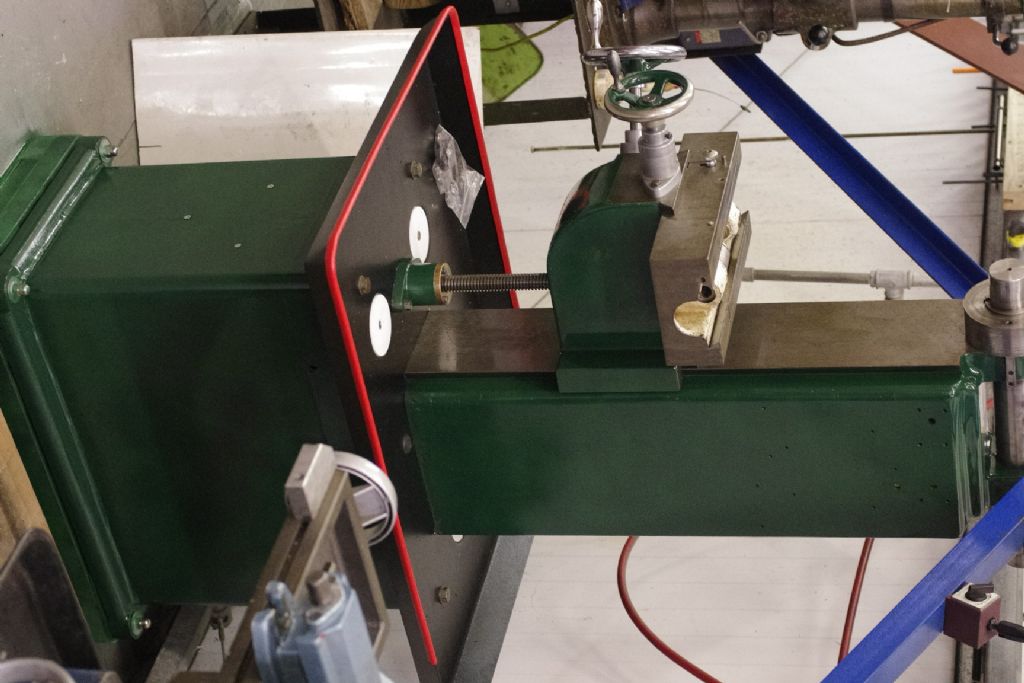

We have the mill bolted down on the 4" of wood using 12mm studding glued into 4" holes in the concrete floor. The machine is not being fully repainted, just a good abrading of the paint and a spray of Plastikote lawngreen paint. The colour is a brighter green than the top of the can suggests, so not exactly concours, but it seems to be oil resistant. The tray got sprayed Hammerite satin smooth black, and has a red strip surround intended for car doors.

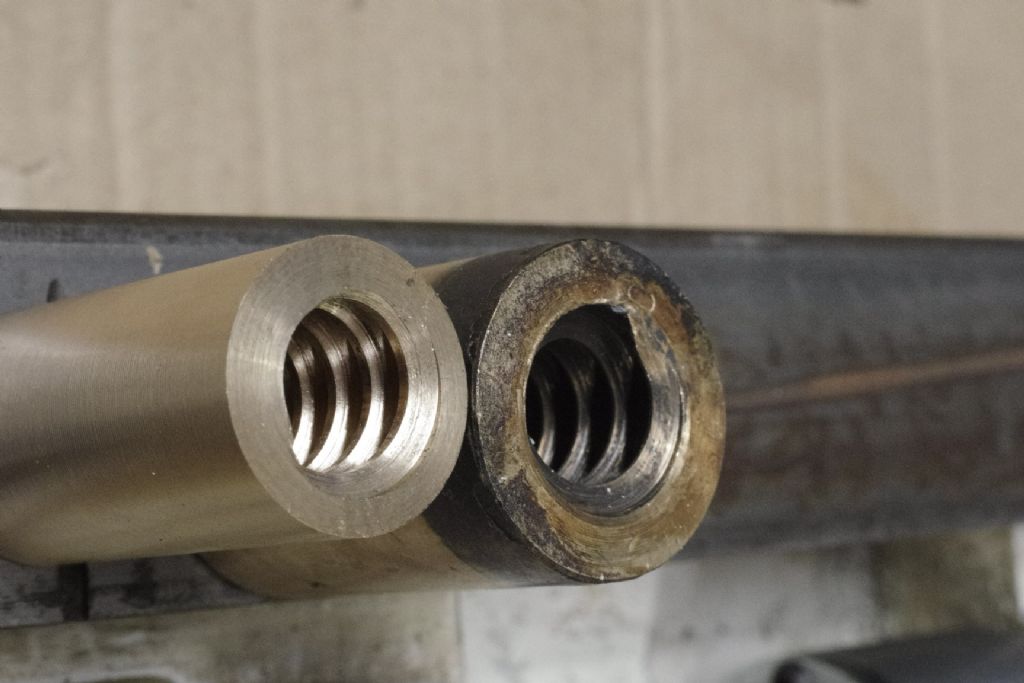

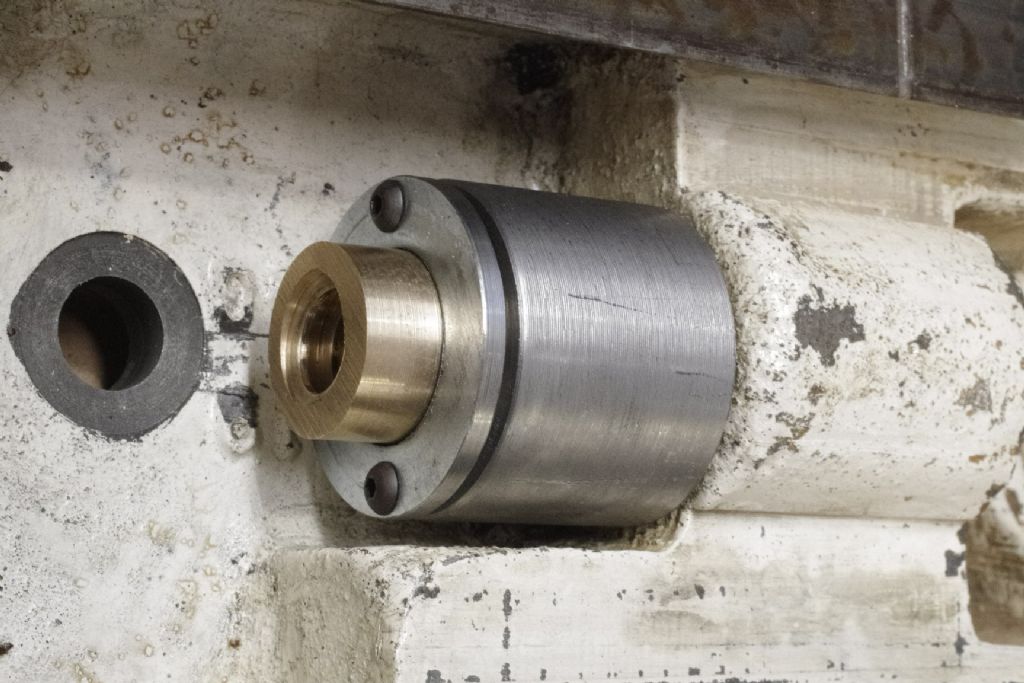

We were lucky with the Y axis leadscrew nut, which in conjunction with new metric thrust bearings, seems to have only 0.001" backlash, I haven't checked it with a dti yet. The thrust bearing housing had to be bored deeper and larger diameter to accommodate the larger metric bearings, which are much heavier duty than the originals.

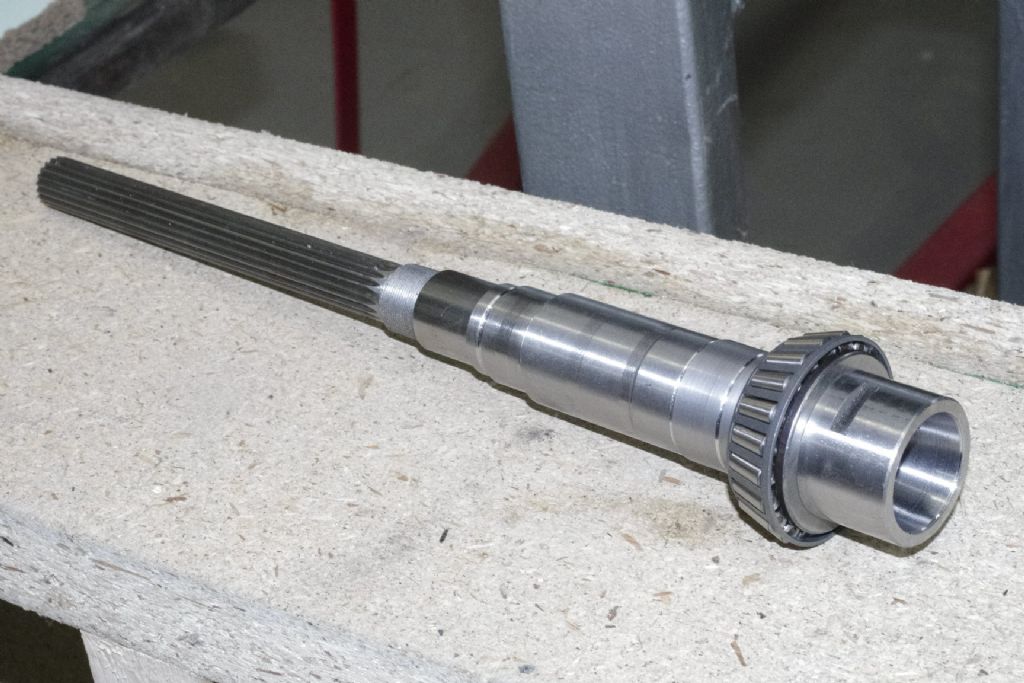

I am just starting the conversion to R8 spindle taper. I have an SKF taper roller bearing 35-62-18 for the bottom of the spindle. Also a spindle from ArcEuroTrade intended to fit one of the Chinese mills they sell. The spindle was bought because I didn't feel confident in producing the internal dimensions well enough. The spindle has been checked for accuracy and concentricity and to my relief, there is nothing over 0.0005" tir.

Simon Williams may be interested that prior to disassembling the head, I found that his mill is not the only one that has needle roller bearings in the spindle drive. The machine was made in 1969, has the long bed, the later style quill lock and all the castings have the same assembly number 7 stamped on them. A bit of a mystery.

old mart.