Posted by Chris Trice on 15/03/2019 00:49:57:

Posted by SillyOldDuffer on 14/03/2019 20:10:42:

Posted by Chris Trice on 14/03/2019 18:51:48:

Posted by Michael Gilligan on 14/03/2019 17:45:32:

Posted by Neil Lawton on 14/03/2019 17:10:49:

…

…

…

…

…

It's not about chasing tenths of thou's. It's about the failure to meet the basics claimed for the product. One would expect a collet chuck designed to fit a Myford spindle would actually be able to be screwed on and not be too small. It's not unreasonable for the customer to expect the product to actually do that simple thing.

I see buying tools in terms of Risk Management, which boils down to money in the end. Nothing provides an absolute guarantee. Brand-names, high cost, country of manufacture, reputation are all unreliable indicators.

- Equipping the workforce of a professional organisation with unreliable tools is bad business. As stoppages are painfully expensive because overheads carry on regardless it makes good sense to pay full whack for reliable tools, but even this may not save you. HMS Triumph, costing about £400M new in 1991 was found to have one of the oval frames welded in upside down, distorting the hull shape and affecting the submarines performance. I don't know who paid to have it fixed, but given the very high cost, it was probably the customer. At the very least the customer paid for the delay, including the cost of the highly trained crew.

- Second-hand is considerably more risky. The condition of the machine is unknown. It might be good, it might be poor, or it could even be a collection of old bits with an impressive paint job. Professional buyers know what to look for, and a business might buy-in the necessary experience, or insure against the loss. Nothing wrong with taking a calculated risk, but if it goes wrong, the customer's left holding the baby.

- Hobby tools are both an opportunity and a risk. It's true that some items aren't fit for purpose. But, if bought locally from a reputable seller you have a very good chance of getting your money back, or a swap. The risk is quite low – hassle, and perhaps return costs. It's also possible, and the same is true of wonky second-hand purchases, that a hobbyist will happily set to and fix it. Rather than getting hot-under the collar about minor flaws, treat the item as a stepping stone.

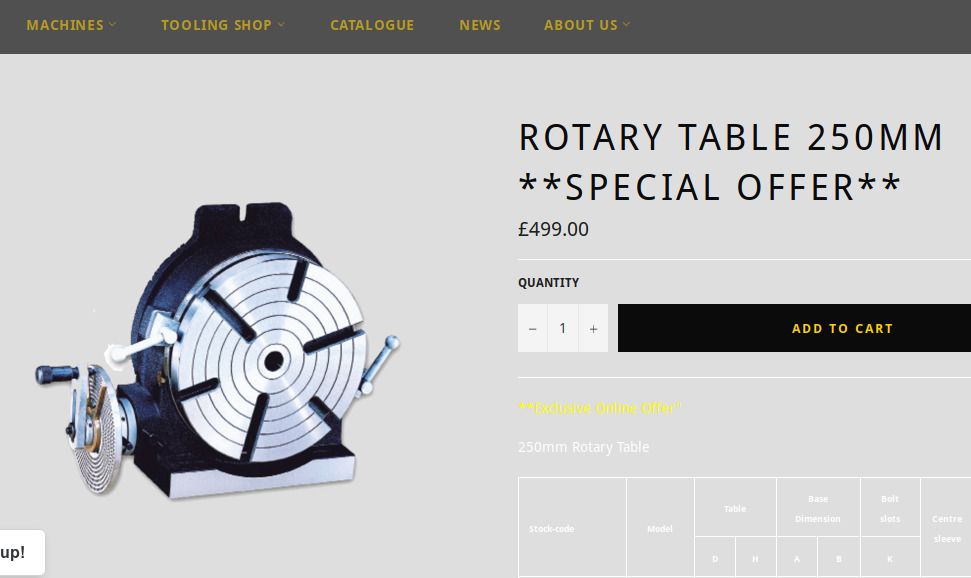

I'm grateful that cheap hobby tools are available because they enable me to do what I want at the price I'm prepared to pay. My inexpensive rotary table is typical – it's a bit rough, but it works. Perhaps I've been lucky, but – so far – I haven't received anything unacceptably bad.

A better target for customer rights might be the travel industry. Certain budget airlines have extremely low reputations: extra charges, unreliable, refusing to pay compensation, losing luggage, and contempt for customers. Nonetheless they remain popular, the reason being that most of the time they get you where you want to go at rock-bottom prices. And buying a railway ticket does not guarantee a seat, or that you will be allowed to board the train, or even that the train will run at all…

Dave

Sakura.