Nigel,

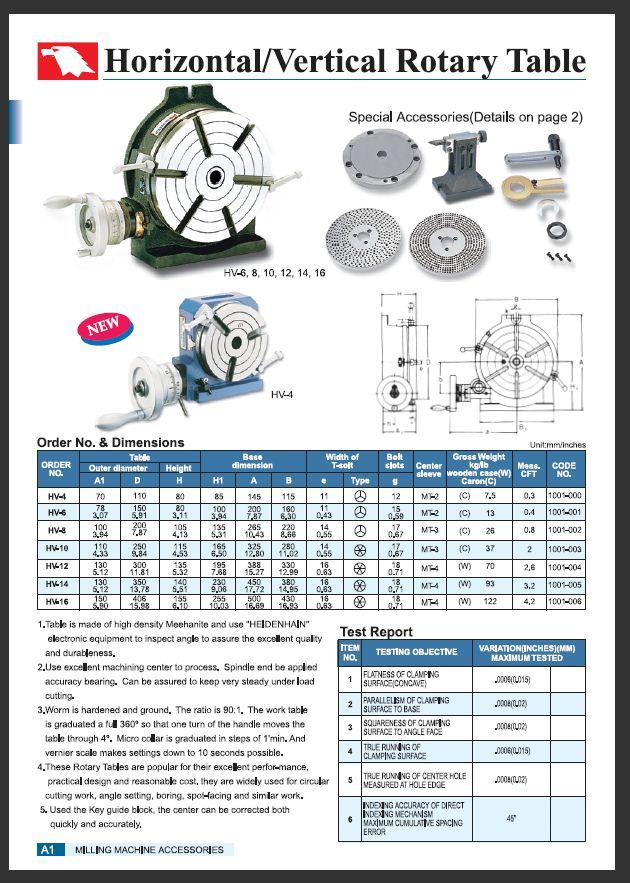

After I bought my Vertex 4″ RT, I looked at making an adaptor plate to bolt onto the vertical slide so that the winding handle was at the top and facing me.

As I did not want to start drilling holes in the Myford vertical slide willy nilly I decided to buy a tee slotted angle plate (designed to fit on the Myford cross slide) from your favorite and mine, RGD tools.

The new angle plate was bolted loosely onto the cross slide with the vertical face just overlapping the left hand edge leaving sufficient slack in the bolts so that when the RT was abutting the angle plate I had a modicum of a self aligning facility with the lathe headstock axis.

I then fitted a 2mt arbor with a parallel extension into the mating taper of the RT.

then clamped the parallel extension in the three jaw chuck and wound the angle plate on the cross slide up to meet the mounting face of the RT.

I could then align the angle plate with the RT by use of the cross slide travel and when finally bolting the RT to the angle plate it would be dead on the centreline of the headstock spindle in the vertical plane as near as makes no odds,

Now I was able to determine exactly where I was going to drill the mounting holes (after previously checking that no harm will come to the internal gubbins) through the angle plate and subsequently spotting through into the base of the RT.

I then dismantled the internal gubbins from the table and drilled and tapped four M6 mounting holes that were spotted through from the angle plate previously and then cleared out the cast iron swarf generated. I drilled the holes in the angle plate 8mm dia. to allow some clearance for alignment purposes.

When ever I use the setup now I first mount the assembly in the three jaw chuck using the parallel arbour in the RT and then bring the angle plate up to the base of the RT and bolt up securely onto the RT and the cross slide.

Sorry if this was a bit long winded but I thought it would help the newbies as well.

Len P.

P.S.

Please note that using this arrangement there will be no vertical adjustment of the RT only longitudinal.

Edited By The Merry Miller on 24/10/2011 20:33:42

Edited By The Merry Miller on 24/10/2011 20:39:07

norman valentine.