Posted by ChrisB on 13/08/2019 09:47:16:

There is very little advantage and lots of disadvantages cutting it the way you show.

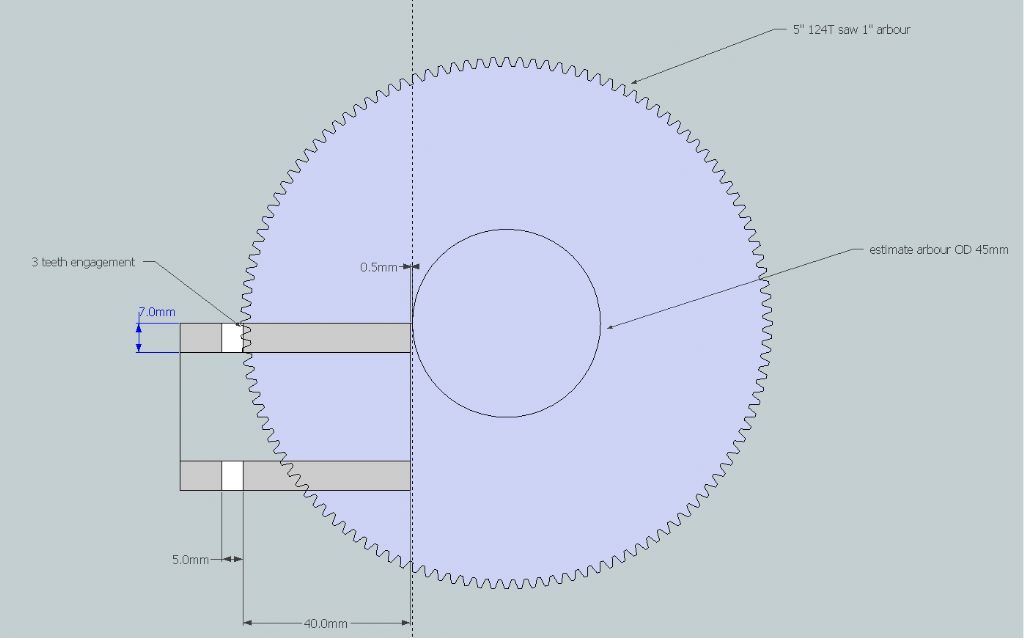

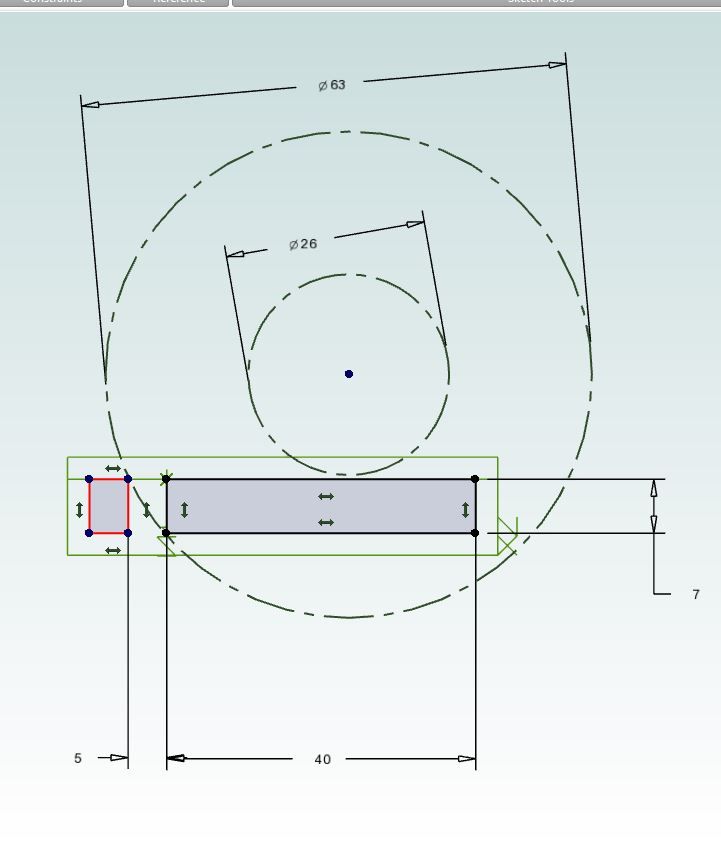

Right now, the teeth are cutting almost vertically. It might pay you to reduce the depth of cut so the lowest tooth on the saw just breaks through the wall of the tube. In this way, the teeth are cutting much closer to horizontally and the length of cut is at its maximum.

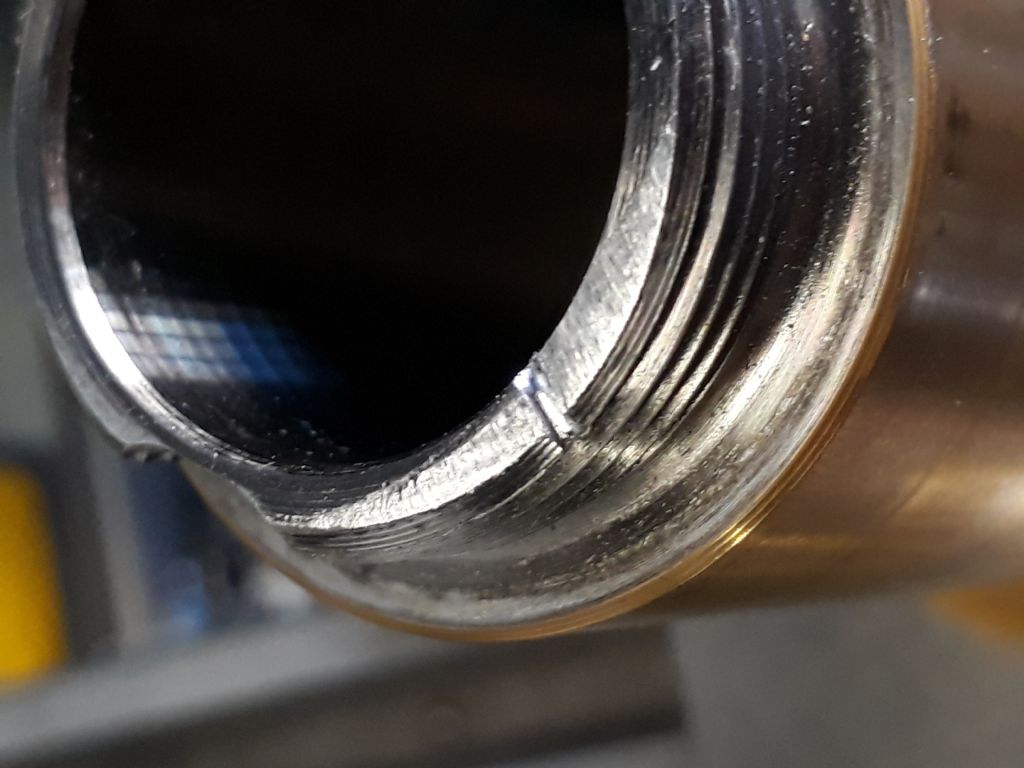

If you have some spare material, or similar material, turn up a close fitting plug for the bore and low-strength loctite it in. This will greatly increase the rigidity of the part and stop it flexing and trapping the saw as more cuts are put into it. Slitting saws do not like vibration. With the plug, and semi-horizontal cutting, you might be able to sneak a centre and tailstock support in. Even if not, support the outboard end with a jack.

Consider the pros and cons of conventional versus climb cutting here. Conventional will try to lift the part off the table, but you are always driving the work into the saw. Climb will push it down onto the table but the saw will try to self-feed.

Me, I'd grind the set off a hacksaw blade, sandwich it between two parallel guides and be done with it. Was it Sir Tubal or Uncle George who ground teeth in a feeler gauge to cut a very narrow slot?

Michael Gilligan.

Michael Gilligan.