Well after pulling out the drive wheel i had a closer look at it …it was very hard no compression at all with fingers or teeth!!

is this material called ebonite?

anyway gently rubbed the surface up with 300g emery cloth then again with the MEK

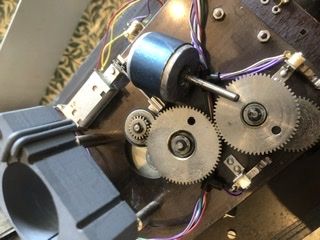

cleaned the shaft as best i could though the drive wheel touches only 5mm from where the spindle exits a oillite bush in the motor and it seemed a lot better…but still could be snappier in operation.

if i helped the solonoid it worked perfectly

checking the voltage to the solonoid it was only 15v dc but if the reverse was used another solonoid pulls in then the voltage drops to 10 v ish

delving into the wiring the motor and lamp are 240v the transformer for the control circuit and focus motor is built into the motor windings…not seen this sort of arrangement before.

the low voltage ac is fed to an old selenienium rectifier then onto the control circuits so i added a 100uf cap on the dc side and now everything works well

cleaned up all the casings which looked rough when i got it off eBay but its cleaned up great and now works fine on the 2×2 side …just waiting for magazines for the 7×7 side.

Nick Clarke 3.