Pretty miserable weather outside and still too windy to go up and replace the tiles lost from the roof over the last week soooo,

More time in the workshop

Continued with the cleaning of the knee. First job was to remove the handle and mic ring etc from the knee feed screw. After the huge effort it took to get the saddle feed handle and leadscrew out I have to say i wasn't looking forward to it!

In the end it took about 5 mins  . Whereas the other mic ring was rusted solid this one was nicely greased up. Took out the mic ring locking screw and the ring just popped off.

. Whereas the other mic ring was rusted solid this one was nicely greased up. Took out the mic ring locking screw and the ring just popped off.

The collet the ring sits on had the same set up as the saddle, one obvious grub screw, a tapered pin and one less obvious grub screw under the ball bearing on the mic ring lock.

After removing these the collet ring itself came off really easily and then the Hoffman bearing and the 2 machine screws holding the spacer ring onto the knee could be taken off.

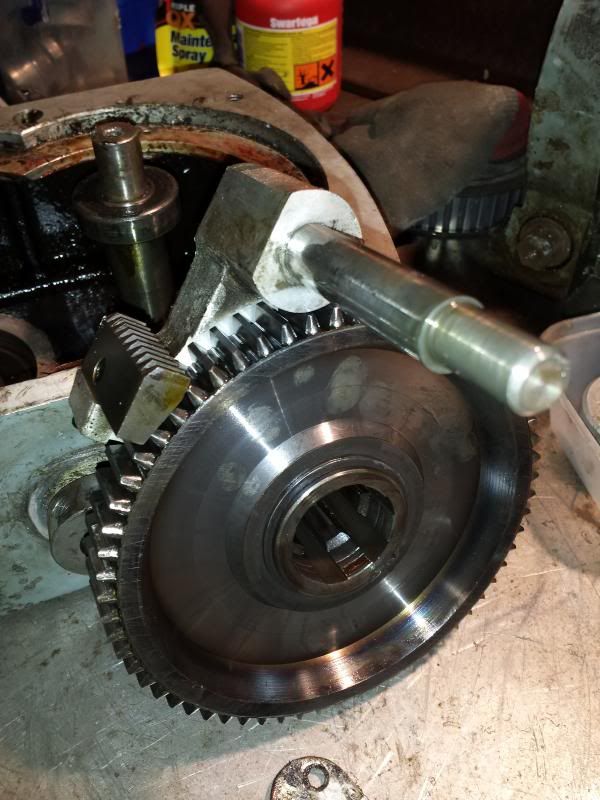

I had already unscrewed the knee pillar from the riser screw so now the complete leadscrew/gears/riser came out as one unit after removing a couple of machine screws that held it to the knee.

The motor for the knee is a later addition. The bevel gear on the end of the leadscrew is held on with a tapered pin, once this is removed the leadscrew pulls out of the carrier.

Next job was to remove the knee retaining plates and gibs.

Started by removing the handle from the knee lock.

The shaft this operates on is attached to one of the retaining plates as you will see in a minute.

Said retaining plates were removed along with the gibs. These are straight gibs on the knee adjusted by a series of grub screws. Some pics of the plates and gibs.

I don't know if the grease points or channels were a later addition but it seems odd that 4 plates have "s" shaped channels and 1 doesnt, and on 3 of the plates the grease point is drilled into the channel and on 1 it isnt!

Plates and gibs look kinda OK, but not got any real experience to go on here about how to check/measure.

What was noticeable was the adjustment on the gibs seemed odd. The top grub screw (in the picture) was snapped off and the middle and bottom ones both had been wound in about 2-3mm whereas the ones in between were flush.

This implies to me the gibs on the knee hadn't been properly adjusted, but I'm no expert!.

I could then give the whole knee a wash down to get all the oil/grease/rubbish off and set it to one side ready for refurbing. I am soooooo enjoying having my new beam, trolley clamp and chain block, it is making this project so much easier

Just out of interest, as part of the refurb I was planning on stripping and painting the mill. This pic gives you an idea of how much filler/effort they put into prepping the mill for paint when it was first produced.

Cheers,

Paul.

Edited By Paul Major on 05/01/2014 00:23:02

Mark Guy.

![[IMG]](https://i1117.photobucket.com/albums/k599/mm289/Workshop/2013-12-27185025_zpsc7dc668b.jpg)

![[IMG]](https://i1117.photobucket.com/albums/k599/mm289/Workshop/2013-12-27184929_zpsfb60c690.jpg)

![[IMG]](https://i1117.photobucket.com/albums/k599/mm289/Workshop/2013-12-27184939_zps0794b057.jpg)