Hi Martin

I go with Ady on the subject of old British motors, 1/4 or 1/3 hp would be fine for your lathe. Adys lathe and my main lathe 4 x 22 are bigger heavier lathes so do benefit from a bit more grunt and as Ady says 1/2 hp is a nice size , but they are heavy the 1/2 hp i`m using is a dual voltage so has two sets of start winding`s,so t`ant `arf heavy !!. always worth buying if you see one for sale in the small adds local papers, etc, and yes they do usually look like crap even if their a bit rattle`y its only going to be a case of new bearings and, or a bit of tinkering about with the c/f switch

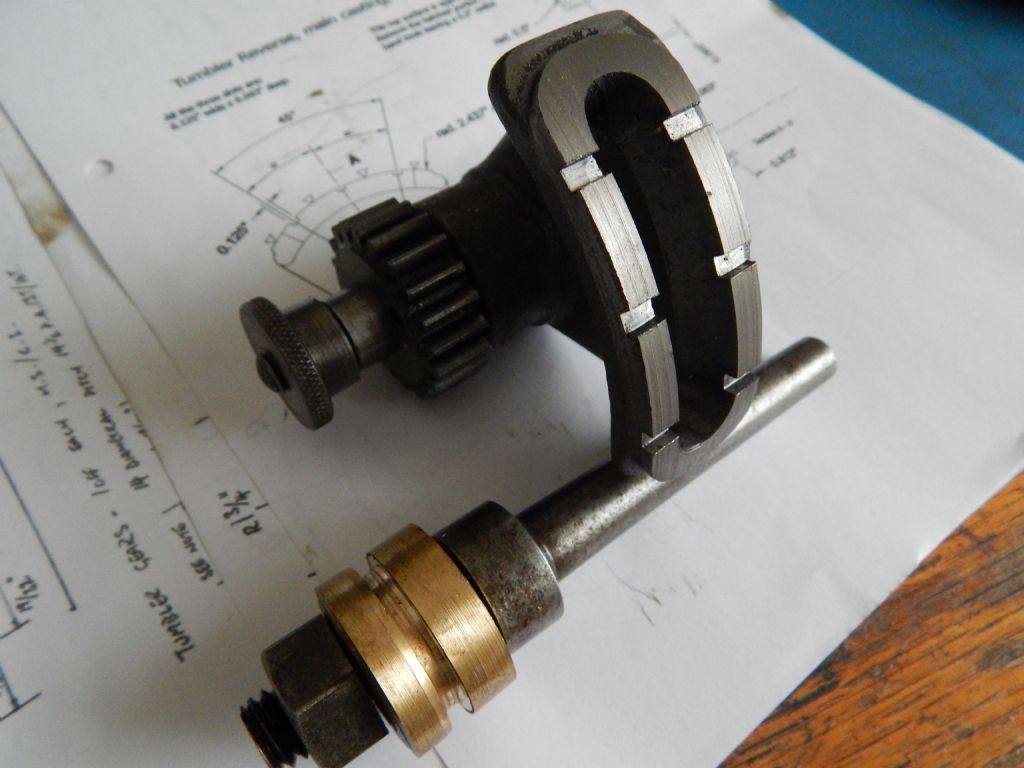

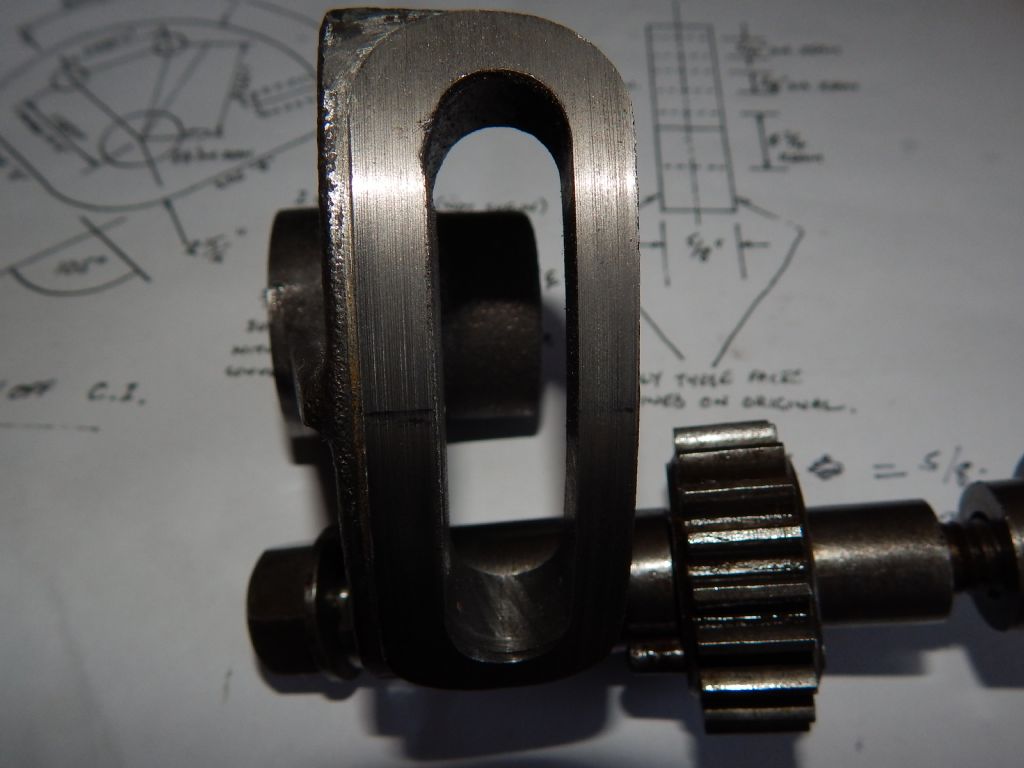

Pleased to hear you got over the quadrant plate problem, I think if i ever get round to it, will make it all in steel which is not a problem ! in the mean time for the amount of use it gets will just stay with the reversing stud. Interesting arrangement on the the banjo arm on your lathe

it's an old AEI from the 1960s . Thats a nearly new one Ady ! got a 1/4 hp dates from sometime around WW1 all cast iron, and still running ok, the motor on the 4 x 22 dates from WW2 ( so does the lathe ) and does run nice and quiet as they should do !……………..b

Martin Newbold.

. Am hopefully going to cut slots next which is a bit of a challenge as have been told that the 1/8" Fluted mills just destroy themselves when you try to use them . I am hoping I can achieve these with a rotating saw on an abhor . Will post more when I have this done.

. Am hopefully going to cut slots next which is a bit of a challenge as have been told that the 1/8" Fluted mills just destroy themselves when you try to use them . I am hoping I can achieve these with a rotating saw on an abhor . Will post more when I have this done.