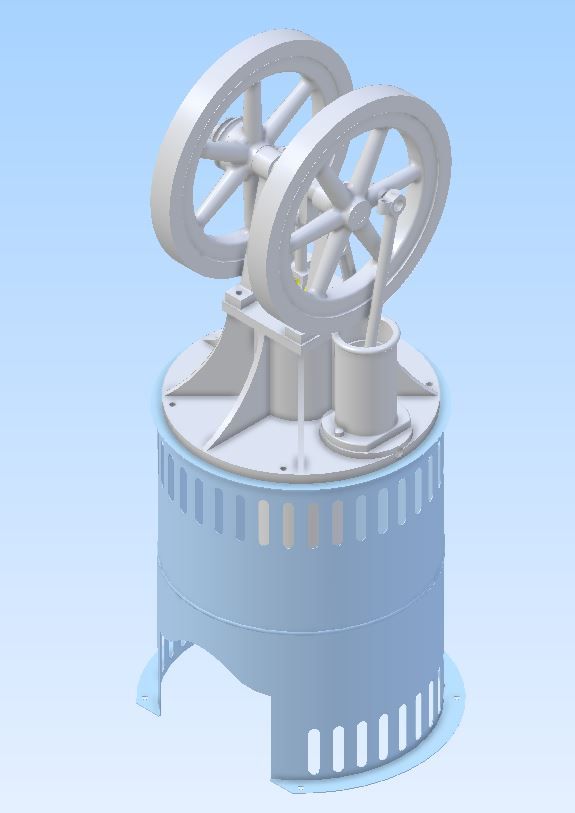

Or a Raab Style Hot Air Engine to you.

I have always liked the look of the Raab hot air engines with their typical buttress fins around the top of the displacer cylinder and while browsing the web as you do came across this listing in a German auction for toys and collectables.

I don’t think it was actually made by Raab but certainly had the look and if built at 1:1 would make a managable sized model so the image was filed away and a few others of similar engines added over time. Earlier this year I decided to start drawing it up, luckily the power cylinder scaled out around the 25mm mark so I decided to do it the same 24mm bore that I have used for a lot of other engines.

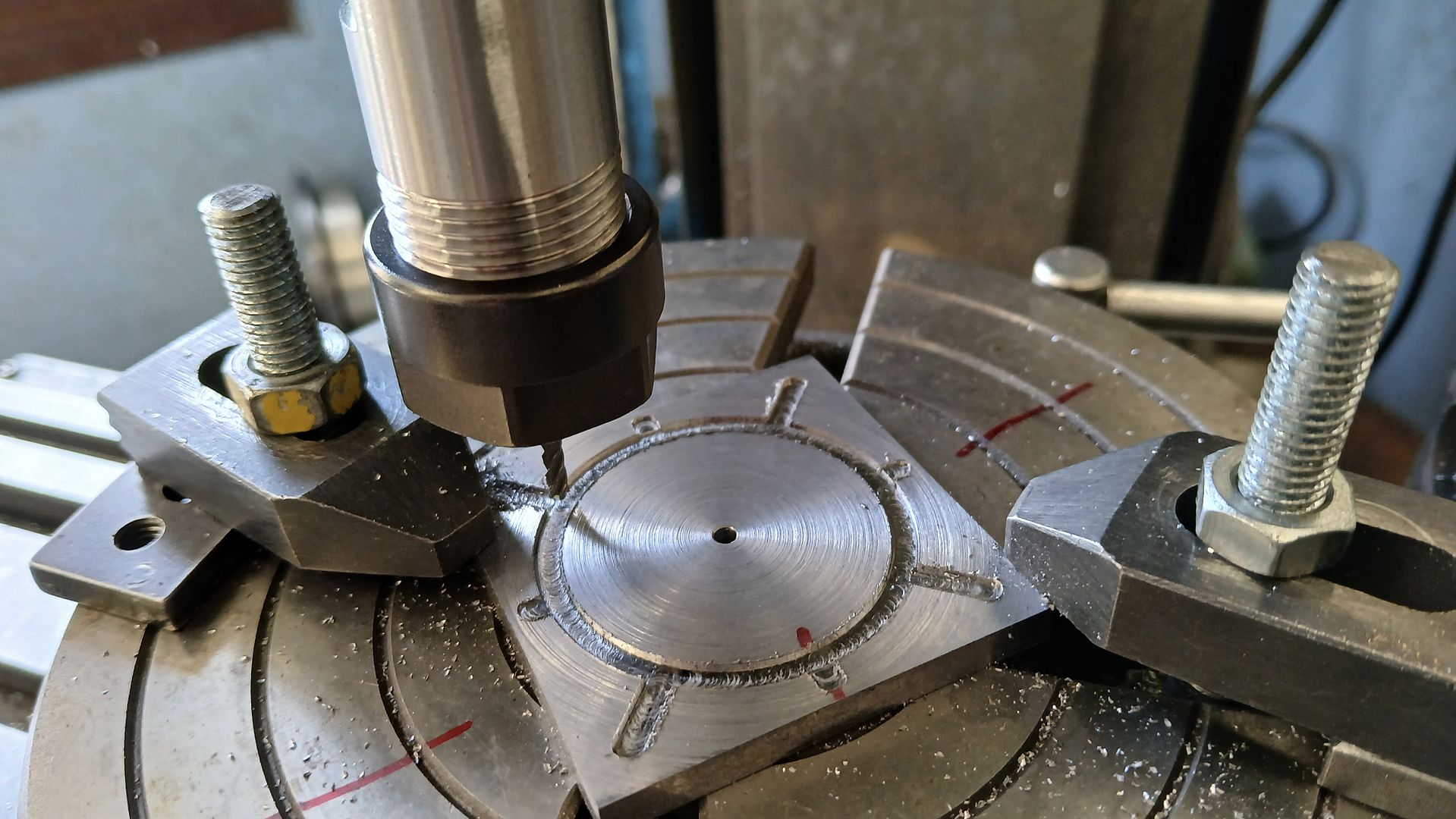

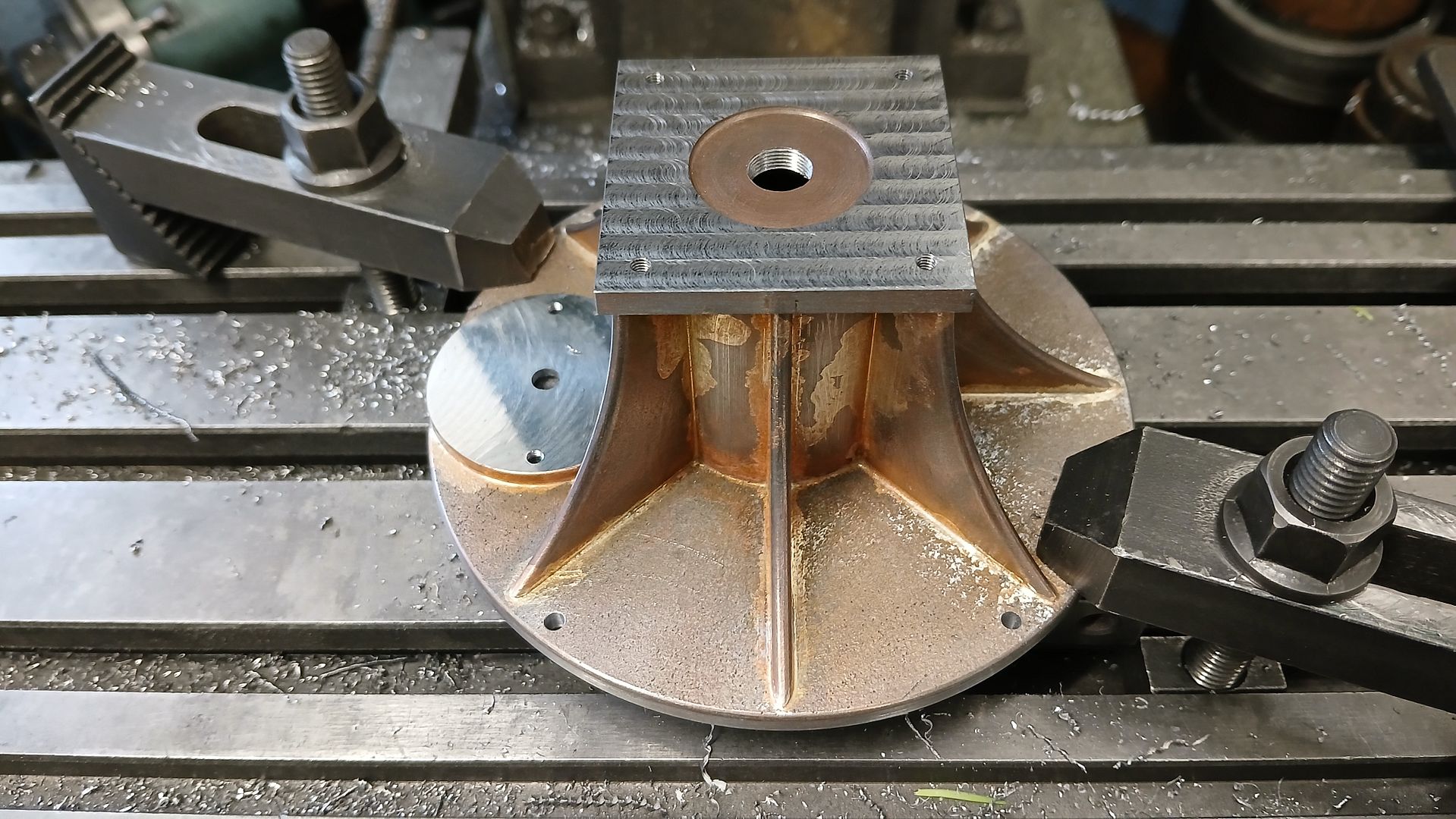

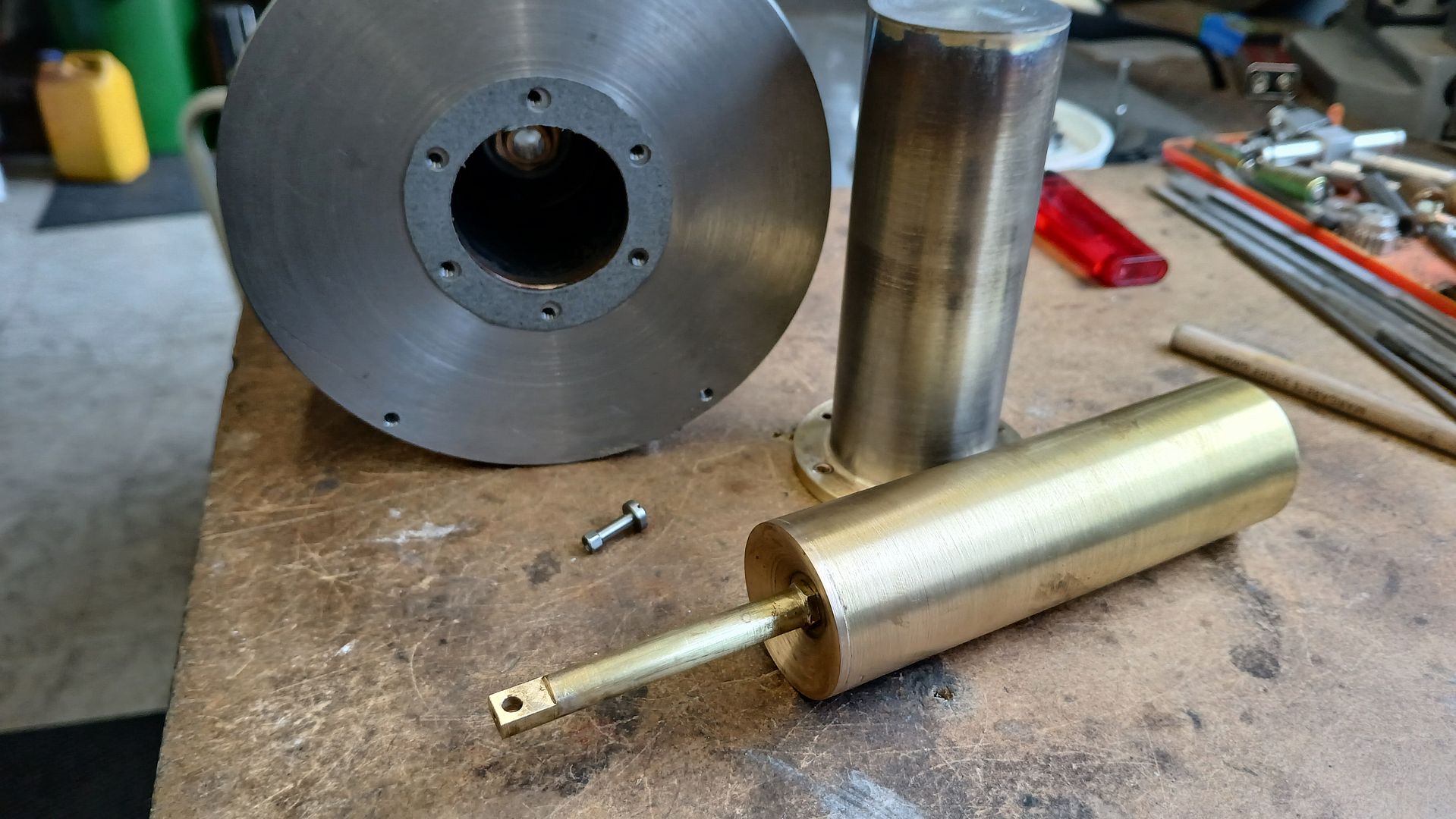

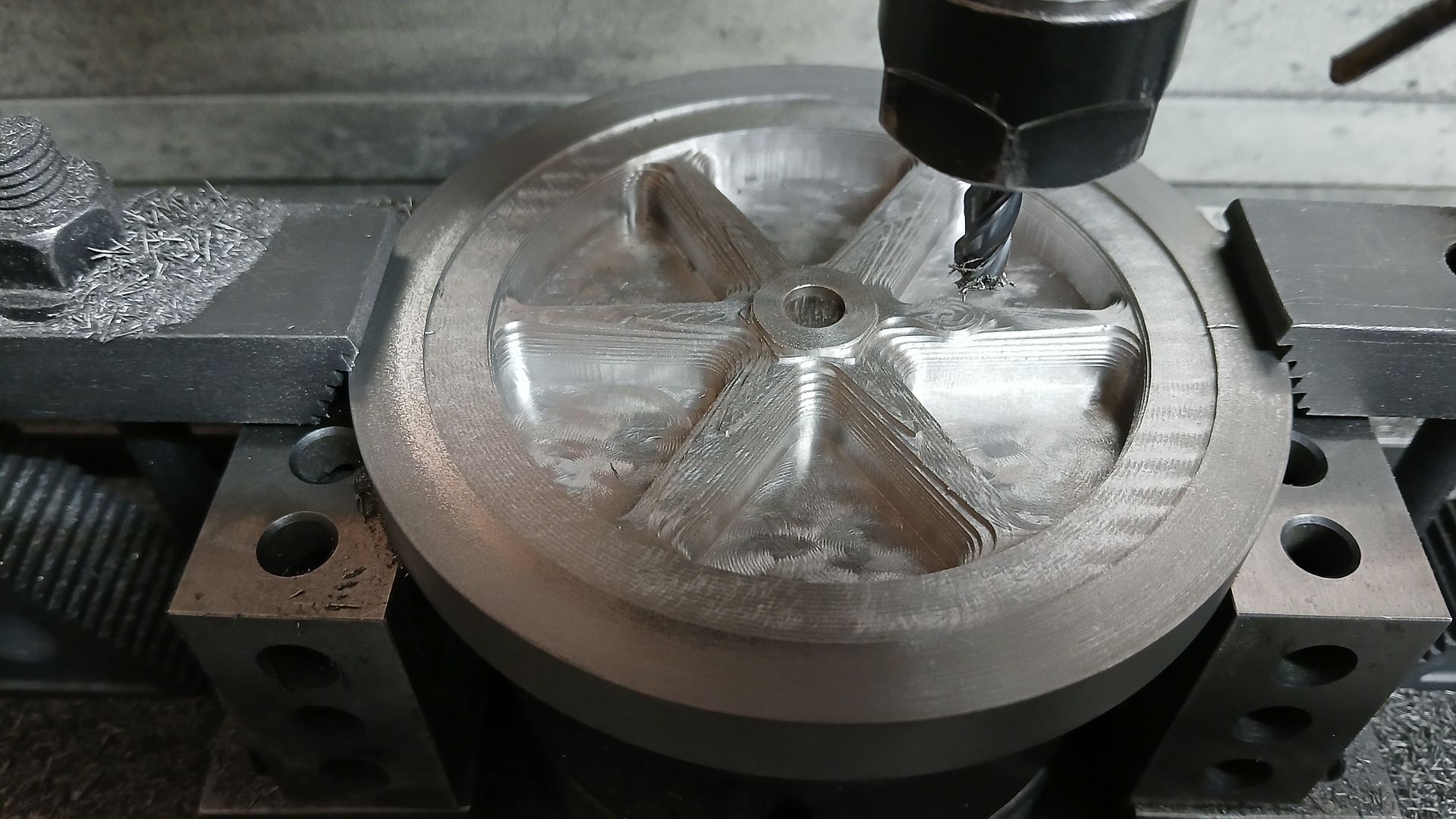

Starting with the most obvious part which is what would have been the main casting with it’s webs a piece of bar for the upper plate was cut and squared up, faced to thinkness in the lathe and then clamped to the rotary table to mill a circular groove and some radial slots to locate other parts of the assembly in.

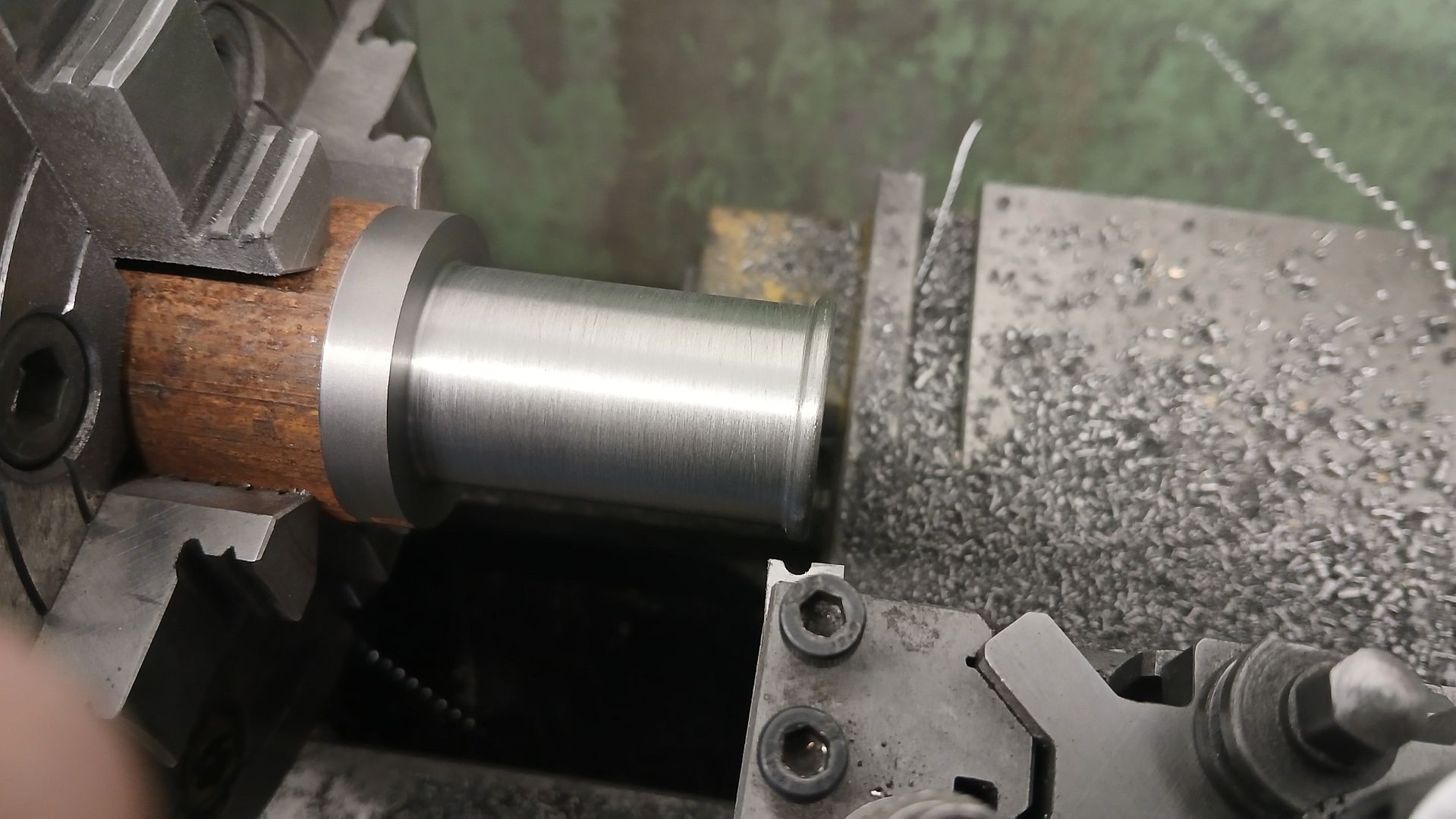

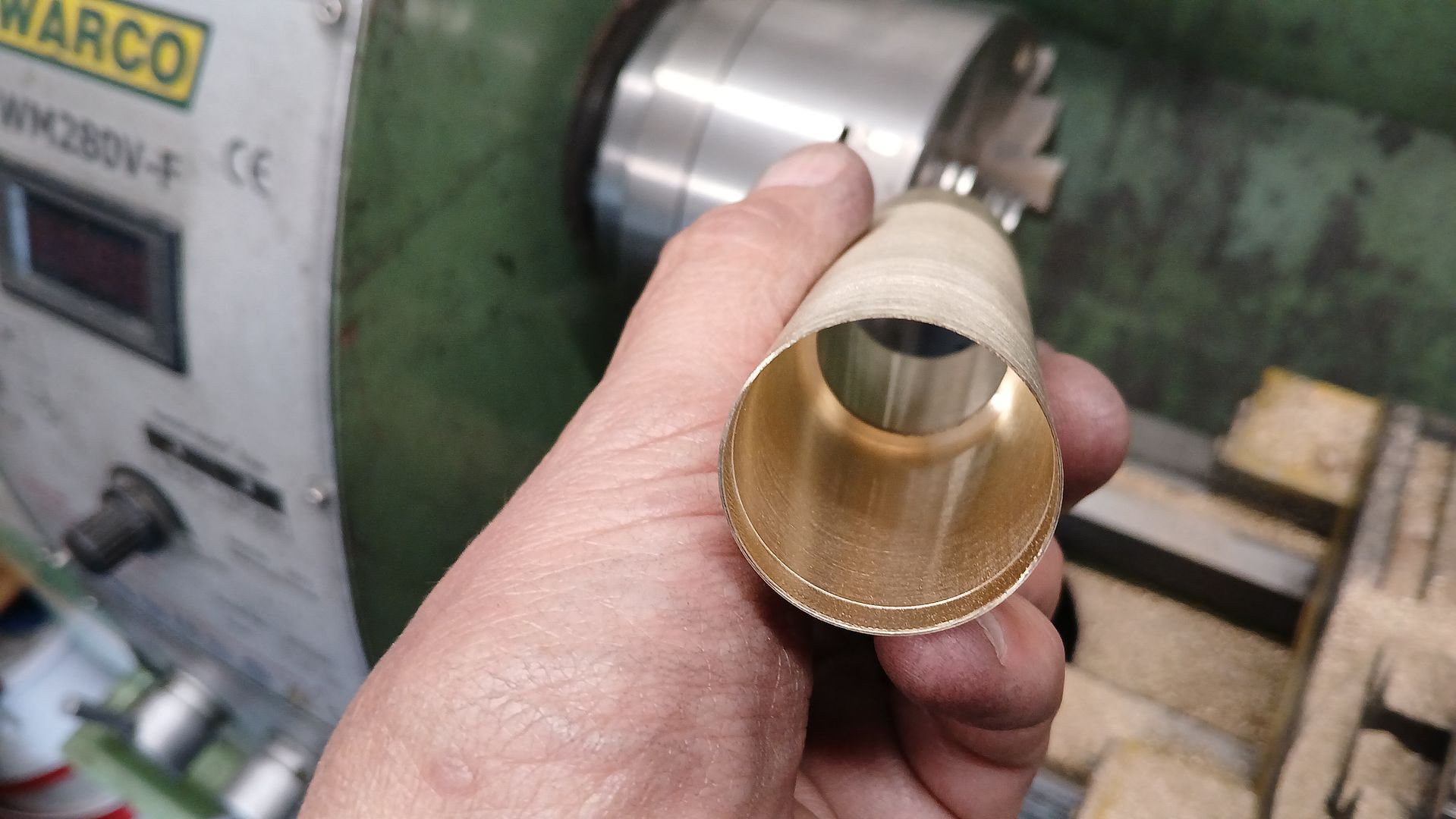

A larger square for the lower plate was bored in the lathe

Then after sawing off the corners held by the bored hole to turn it round.

Out with the rotary table again to do the radial slots. One was done deeper and wider and will act as the linking passage between power and displacer cylinders which was an easier option than trying to drill in from the side at a late date.

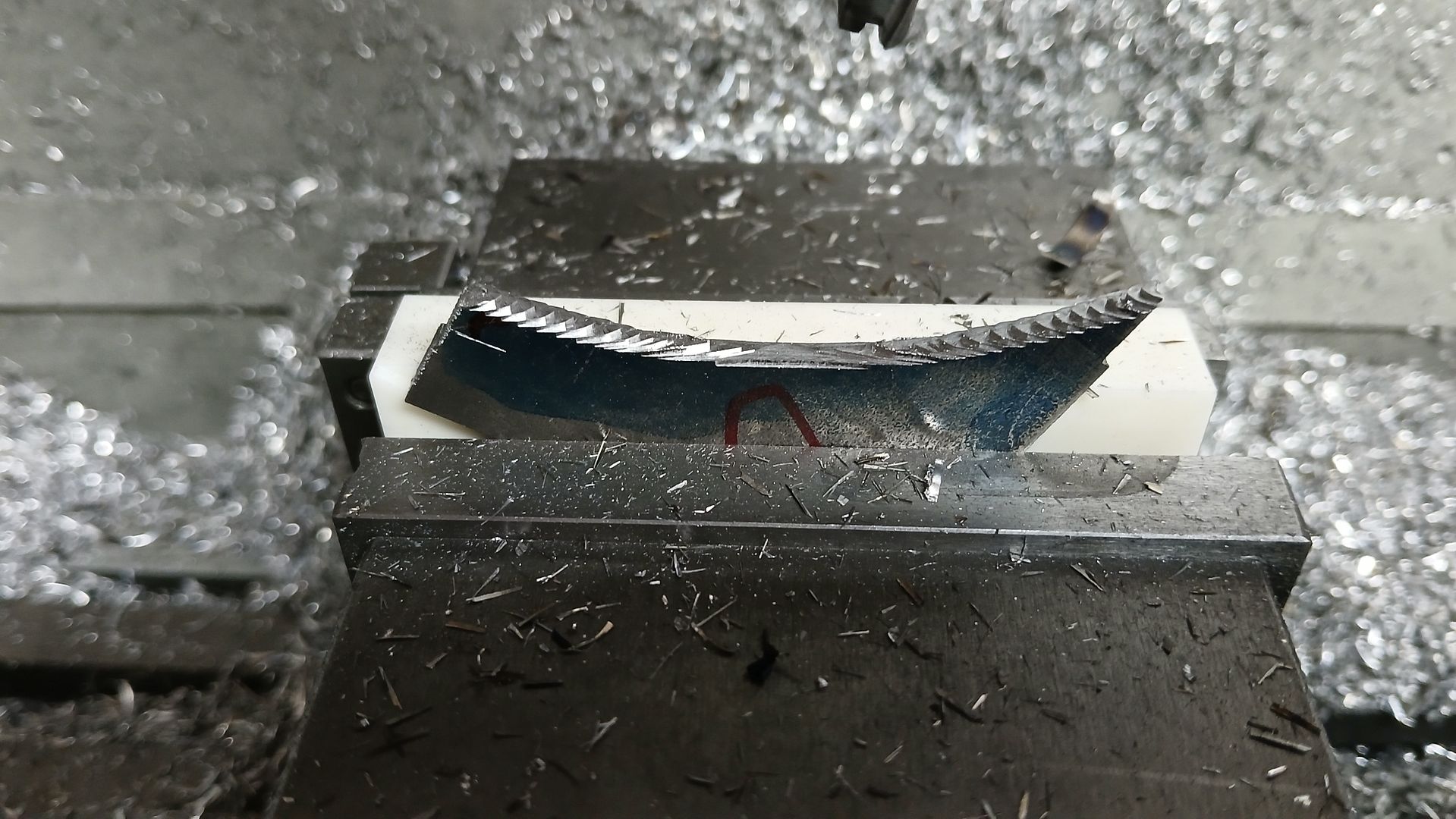

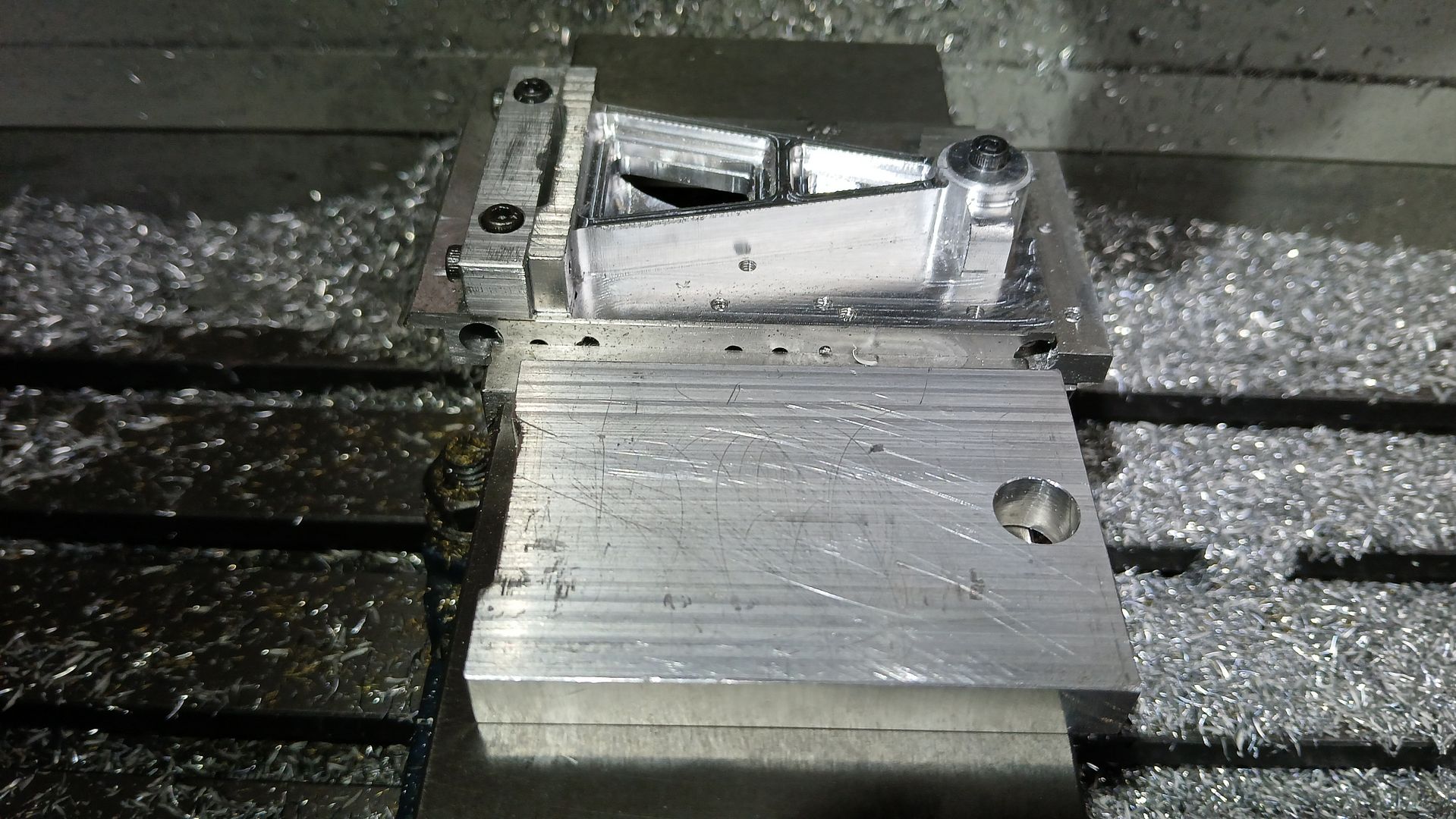

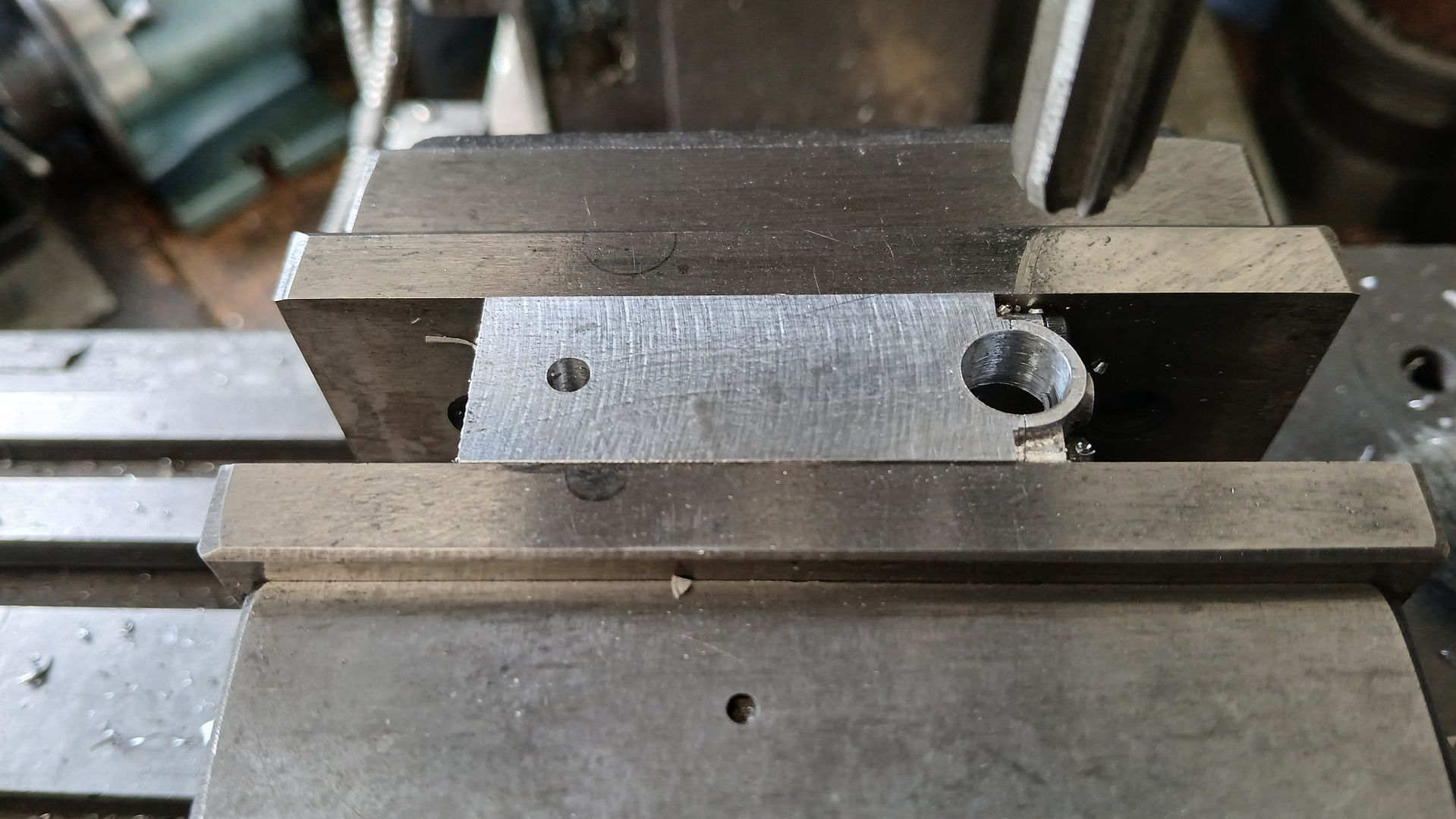

I toyed with a few different ways of shaping the webs – cutting the profile while held flat and then using a 1.5mm roundover cutter along each side of the curved edge, saw and file, etc. In the end I used the manual mill to do the two straight edges and a couple of steps then milled a piece of corian to allow the webs to be held curved edge up in the CNC mills vice.

First an adaptive to rough out the shape

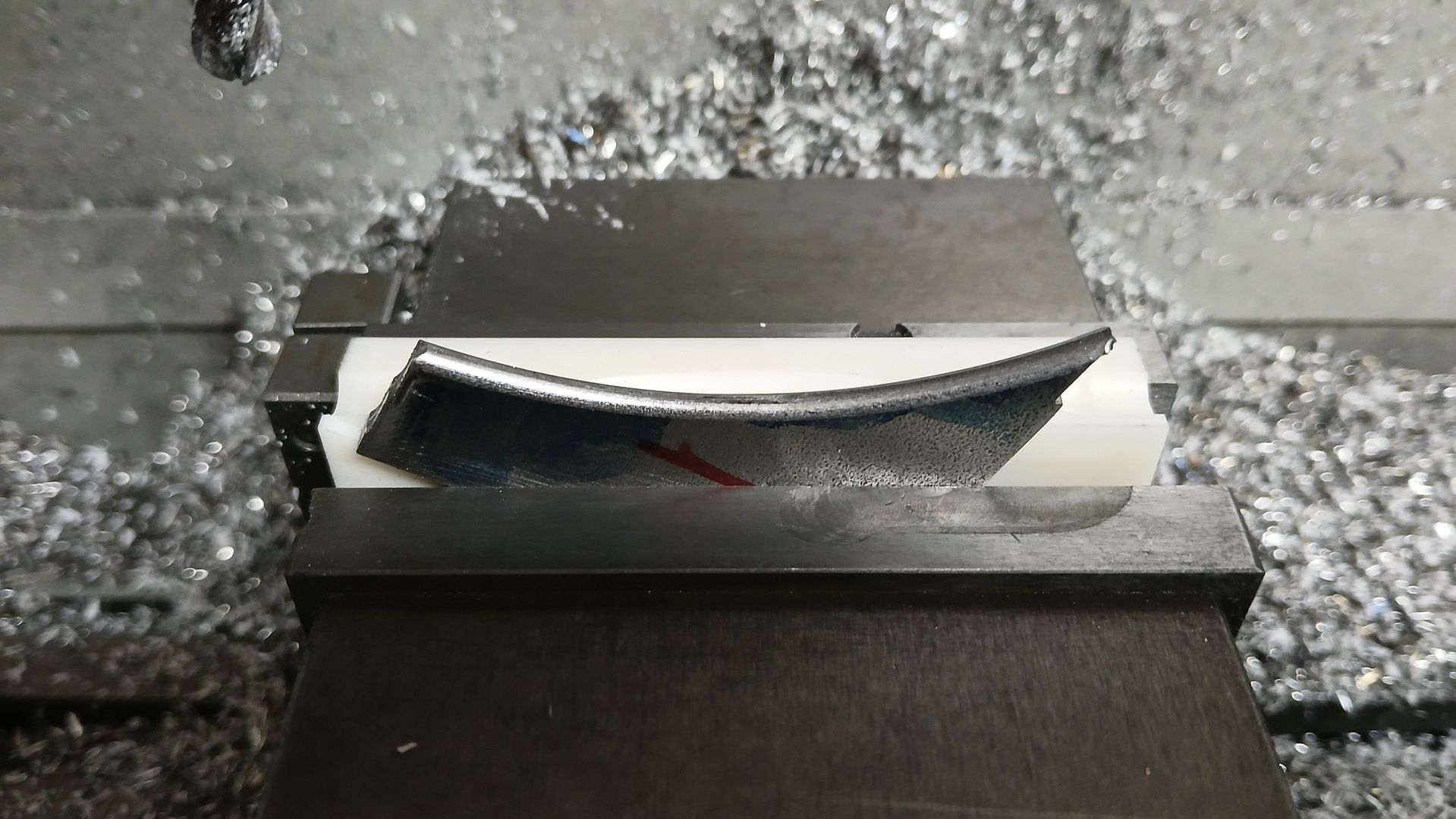

Then a scallop to smooth it all out, Th ecutter moved back and forth along the work in a shallow U shaped path stepping over 0.2mm per pass

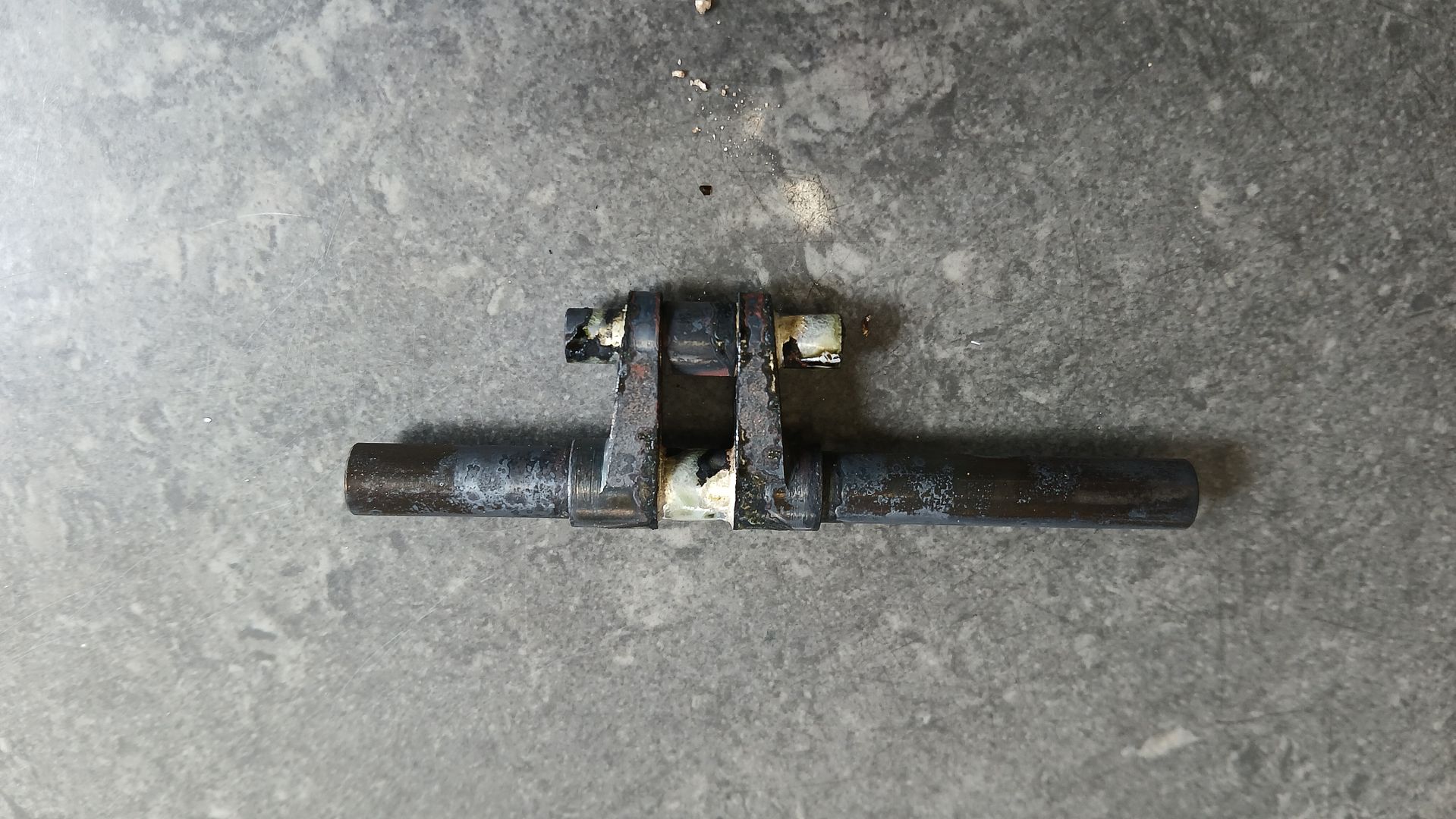

The central cylinder was turned from a bit of old galvanised water pipe

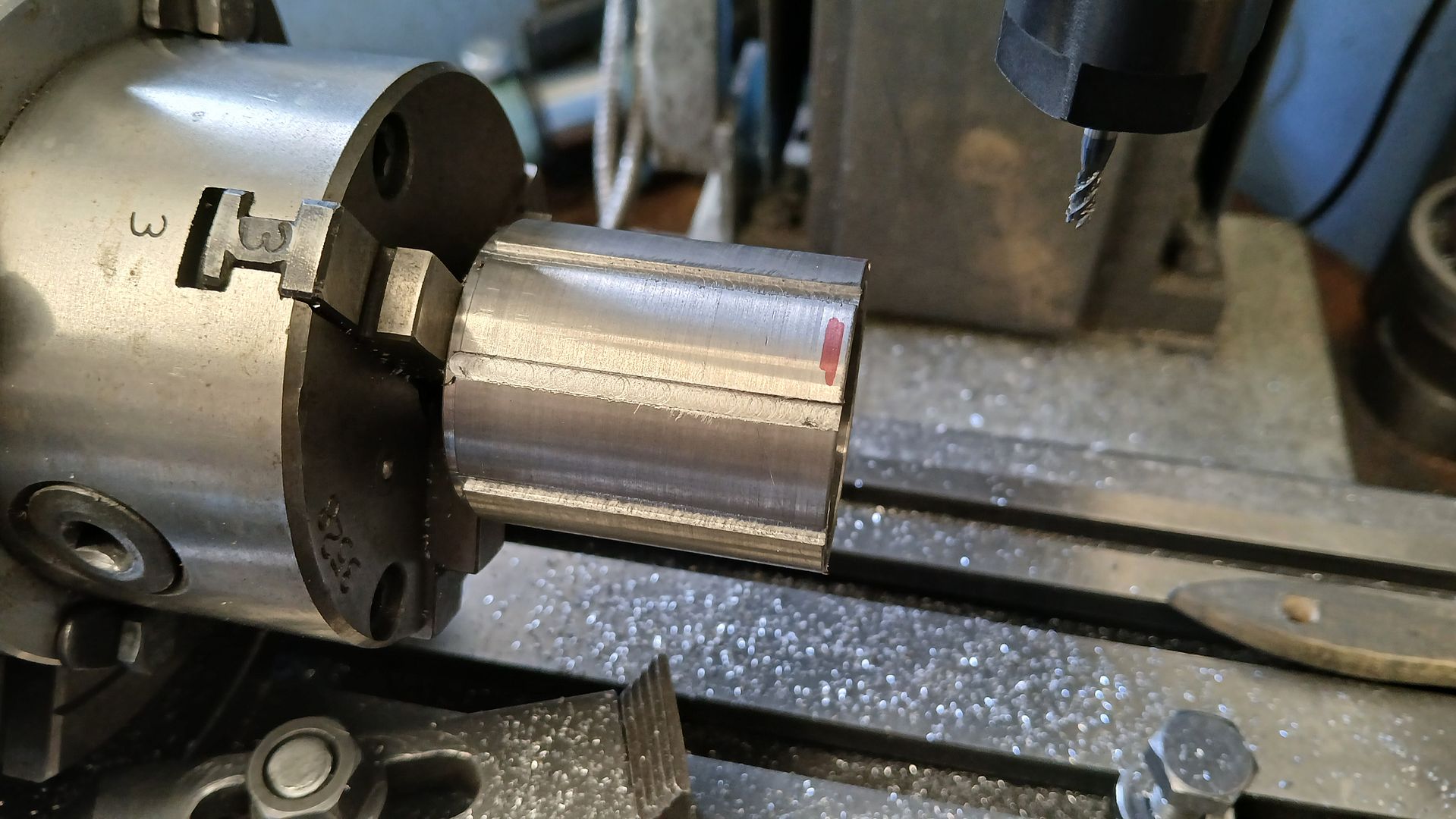

Which then had eight locating slots milled along its length

There was also a round part that the power cylinder will sit on to complete the total of 12 to make up the “casting”

JasonB.

JasonB.