Ok, So I noticed from the previous results of the head movement (that I shared here), that the maximum deviation is in the middle of the column. So I thought maybe I will adjust the gib at that height and see what the results will be. I found out that even if I take the gib all the way down such that the counter screw only holds by one turn (obviously if I will lock it tight I will damage it’s thread) that the head still move by 0.27 mm (it was 0.275mm before) and that now I cannot move the head all the way up by 10 cm, in the picture you can also see the cover shear that I talked about covered in paint. I found someone else here in this forum that also talked about this problem, Piotr, luckily I can still get (hopefully) service from my dealer.

Dave Halford, the old style gib is somewhat flexible compared to the new style, however it’s purpose is the same. there is not much of a different between them, so long as all the parts are properly machined. As I see it, and please tell me if I am wrong, the gib’s only job is to lower the play between the column (bed) and the head (saddle?) of the mill and the more you tight it up the harder it will become to move the head and the wear of all parts involved will increase. In my case since the column (bed) has a trapezoidal shape (wider in the top, thinner in the bottom) both styles will not have helped. The way you adjust the new style (if you want to tighten it up) is by releasing the bolt at the top half a turn, then releasing the bolt at the bottom half a turn, and then locking the top bolt against the bottom one full turn. If there was only on bolt at the top then when the head was moved upwards the gib will have tighten itself while moving downwards and the head would not move.

I also decided to share with you a few more pictures from the first mill I got, so that others may take it into account before buying. The shipping Is by the sea, so obviously high humidity and a lot of salt, you can see in the picture the rust on the box metal strips, and there was no silica gel bag inside. So no wonder the paint peeled off and the screws got rusted, it will probably affect the electronics in the long run.

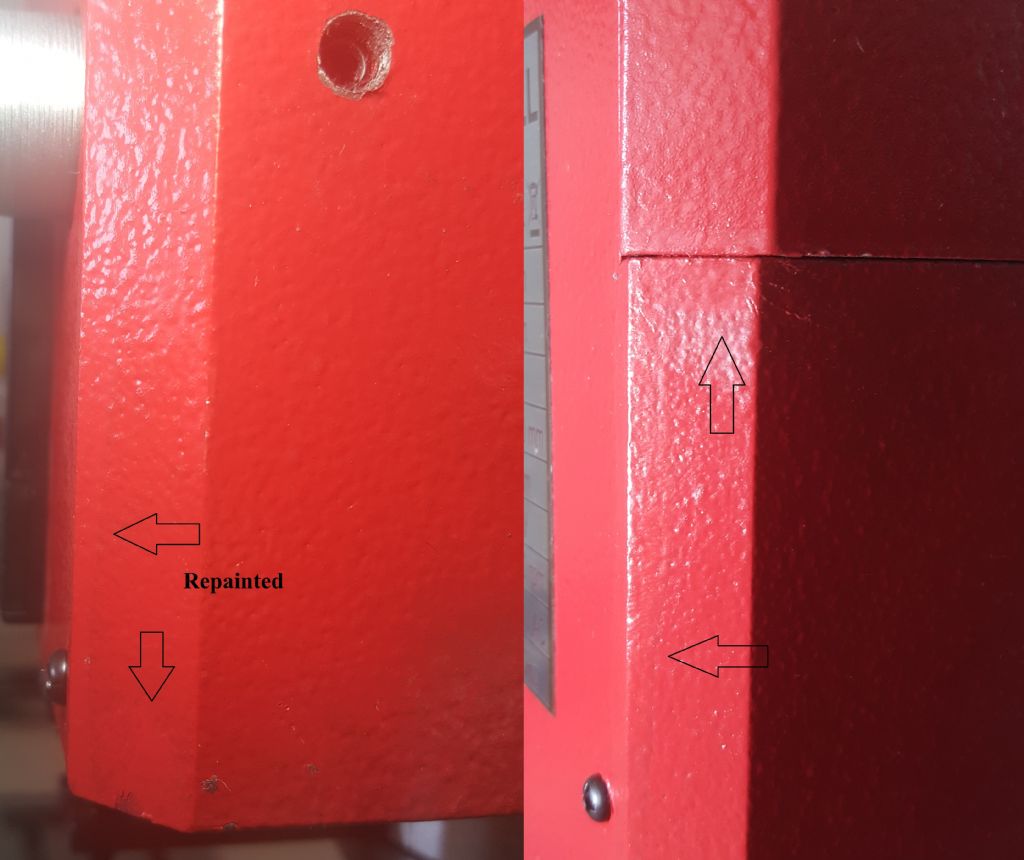

Vic, thank you, I totally agree, which method would you have used? I learned it from the internet… About the mill, it is 100% Sieg fault. The dealer ordered 12 machines (There is a sticker on the box) and when he shipped me the first mill it was after waiting for it to arrive, so it was sent to me directly from the harbor not from his store, and the number embedded on the base was 90415 and after he sent me a replacement, the mill was stamp with the number 90414, so there is no chance he did it. I think that, as SillyOldDuffer mentioned, Sieg don’t put the machines for Quality Assurance (even if I have a triangle piece of paper that says so) when a dealer orders a full container. Maybe they are counting on the name of the brand? Or maybe they haven’t renewed the manufacturing line after producing 100k machines? I have no idea, but I am truly disappointed. I can tell however that the new mill was painted twice, it is very hard to see depending on your monitor, but they have repainted the front with a slightly different tone, the camera doesn't catch it but the eye certainly does…

Thank You,

Nir

Nir Somthing.