Some while back a post was made on the Forum concerning the use of scrapers. Posing the question as to whether they should be pushed or pulled. While I had seen references to pull scraping for recessed surfaces, it was not something I had given much thought too.

The Forum post did however start me thinking and a Google search brought up some very good information and several posts over the years on Forums in the USA. I tried the pull scraping technique by modifying a small Eclipse flat scraper that I had. Although I have done a great deal of conventional scraping in the past, I did find the pull scraper easier to use and more controllable. Also with my muscle problems this method did not give me so much grief.

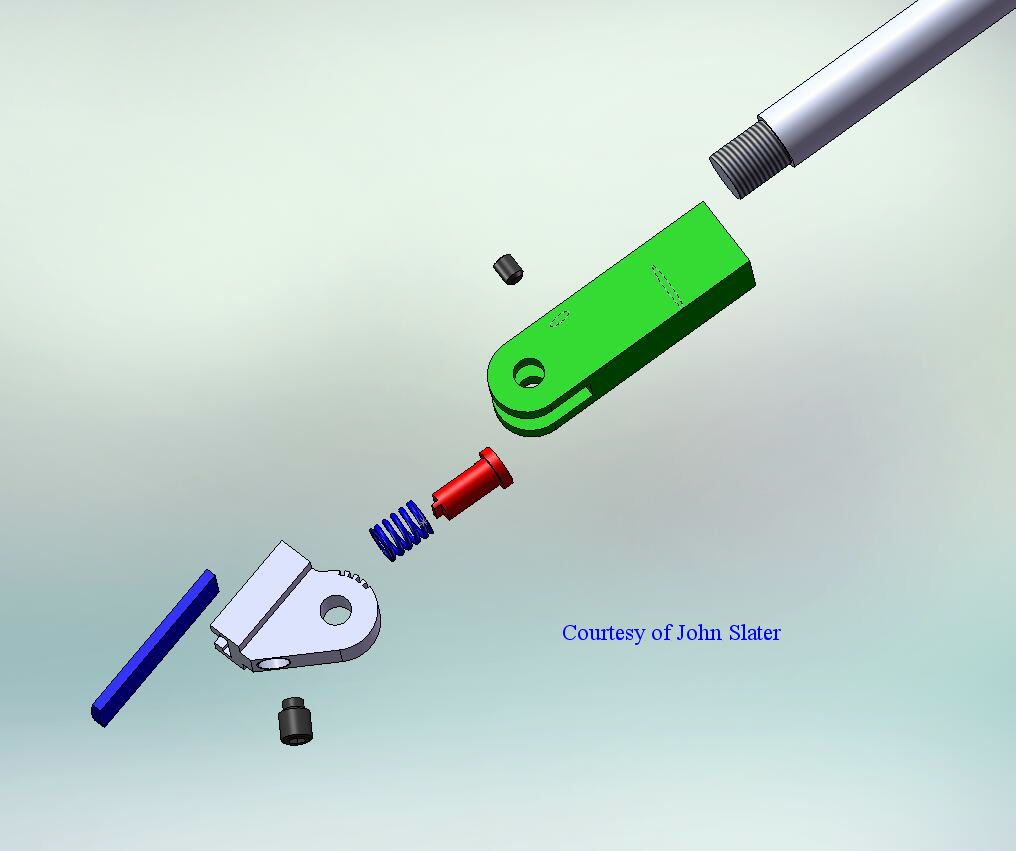

During my searches one design in particular by "Agathon" took my interest and started me off on a design for myself. The above scraper has interchangeable blades of HSS or Carbide. The end faces of which are ground and honed dead square. The resultant face can be at 90 degrees to the blade or at an oblique angle. This allows the blade to access the corners when doing dovetail slideways.

The head that carries the blade can pivot to 5 different positions and in the in-line position the scraper can be used as per a conventional push scraper, with the appropriate blade.

The position of the handles are adjustable to suit each individual user. They are made from one Woodturning Chisel handle. An M5 Wood Screwcert allows an M5 grub screw to lock the handles in the desired position.

Some results from this type of scraping can be seen on the work tables in my post, HSS/TUNGSTEN TOOL HONING MACHINE.

Regards

Gray,

Graham Meek.