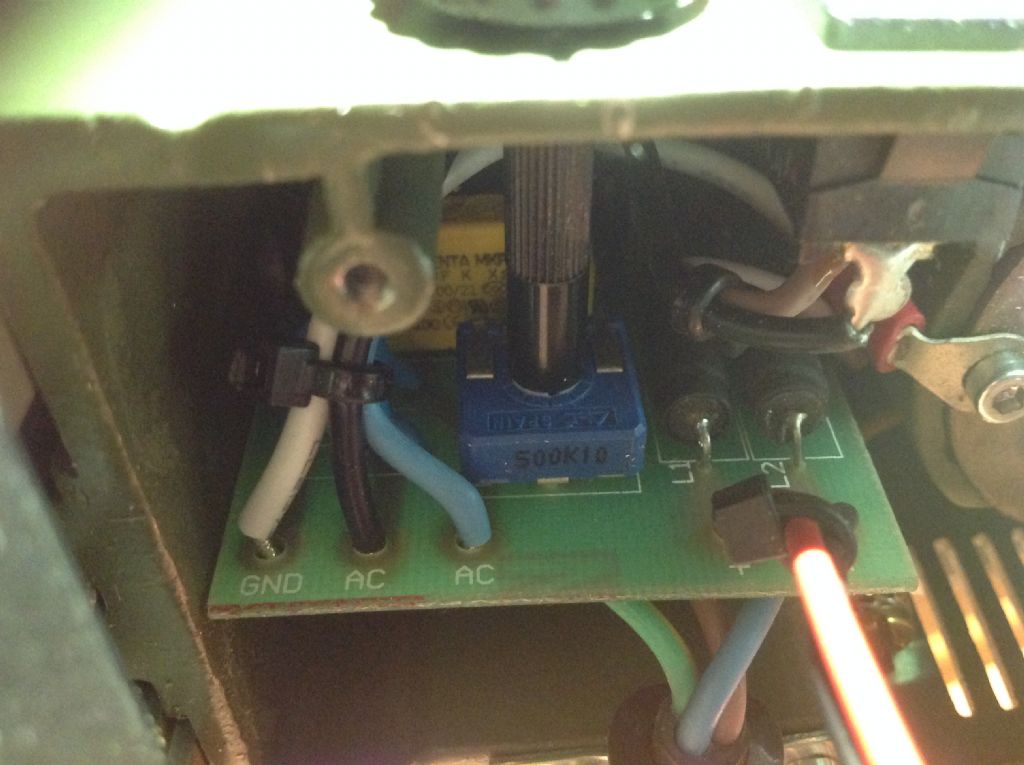

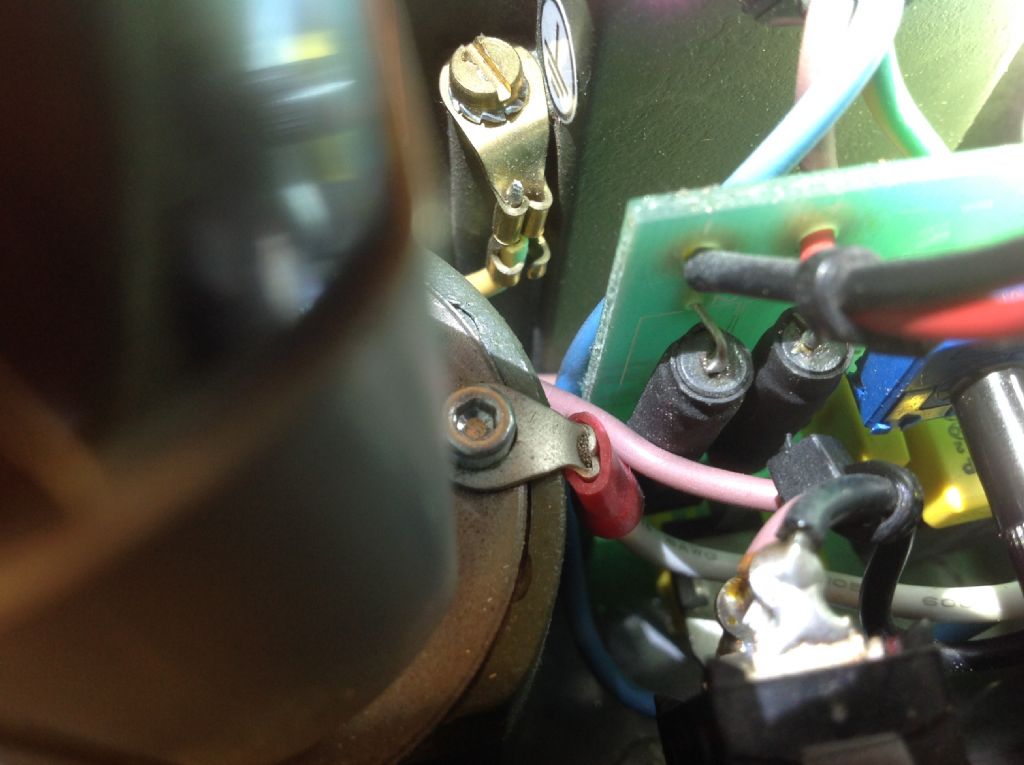

Good photos Bill but no obvious signs of smoke in there, nor of brass swarf having got into the motor /control housing.

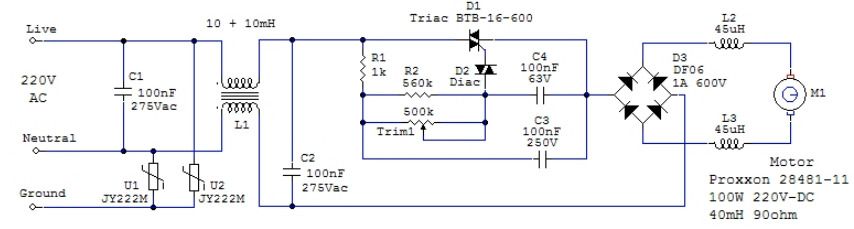

I would agree with Mike and Derek – look at the capacitors first – starting with the big 'yellow brick' (C1 I believe) but I suspect if this has died it might not be easy to test as it will probably have blown 'open circuit' and capacitors are not easy to test without the right meter even when removed from the circuit. If you can unsolder them and have a look at their undersides there might be evidence of damaged casing or the smell of smoke.

The next items I would look at would be the bridge rectifier D3 – the black brick mainly because it is easy to test while in circuit – between each pair of pins there should be a resistance one way and short circuit / 0 ohms with the test meter probes connected the other way round (opposite polarity) . No harm checking the inductors L2 and L3 which should read as, effectively, short circuit (0 ohms) on a multimeter continuity test.

At first glance the rating of D3 at 1 amp looks a bit light for a lathe so that raises the thought that this might b a vulnerable component. That said the motor should only be drawing 0.5 Amp so strictly speaking the rectifier is not overloaded.

Triac also needs taking out of circuit and a slightly more specialist test instrument to check it.

Having got the board out of the housing can you smell smoke on it anywhere?

This is a very simple circuit and if you can find someone with even fairly basic electronics knowledge and a decent test meter they should be able to locate the fault and source replacement components.

Bill Phinn.

f:1&frcectupt=true

f:1&frcectupt=true