OK, thanks. I had hoped against hope that there might be short leg / long leg convention as with LEDs!

The dead legs are too long to feel any difference when the heating is on, so I shall have to plumb in a temporary loop as Jason suggests.

I don't understand why it should matter which end the water goes in, but the installation instructions say:

VERY IMPORTANT:

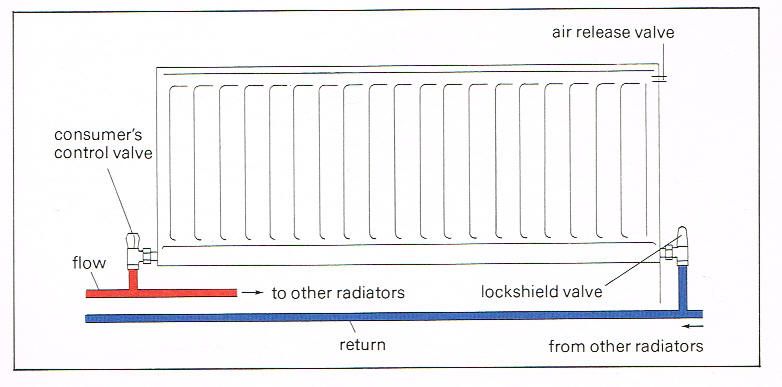

PLEASE NOTE: WHEN CONNECTING THE PIPE-WORK TO THE RADIATOR, THE WATER MUST ENTER THE RADIATOR AT THE BOTTOM CORNER DIAGONALLY OPPOSITE THE AIR VENT AND EXIT AT THE BOTTOM CORNER BELOW THE AIR VENT.

All those boldface caps and underlining make me fear that HELL WILL BREAK LOOSE if I get it wrong. It would be good if they explained why it is so VERY IMPORTANT but they don't.

Thanks again for replies, including digressions – always interesting to hear about plumbing experiences! Plumbing is my most hated DIY house-doing-up task.

Robin

Edited By Robin Graham on 15/03/2021 01:05:17

Edited By Robin Graham on 15/03/2021 01:07:08

Edited By Robin Graham on 15/03/2021 01:14:36

Edited By Robin Graham on 15/03/2021 01:19:28

old mart.