Just for a bit of context, I have no milling machine and where I live, getting blocks of steel big enough to bore a hole to fit that bar into is impossible without prohibitively expensive shipping in, and a week or more wait, so it was definitely a "make do" scenario.

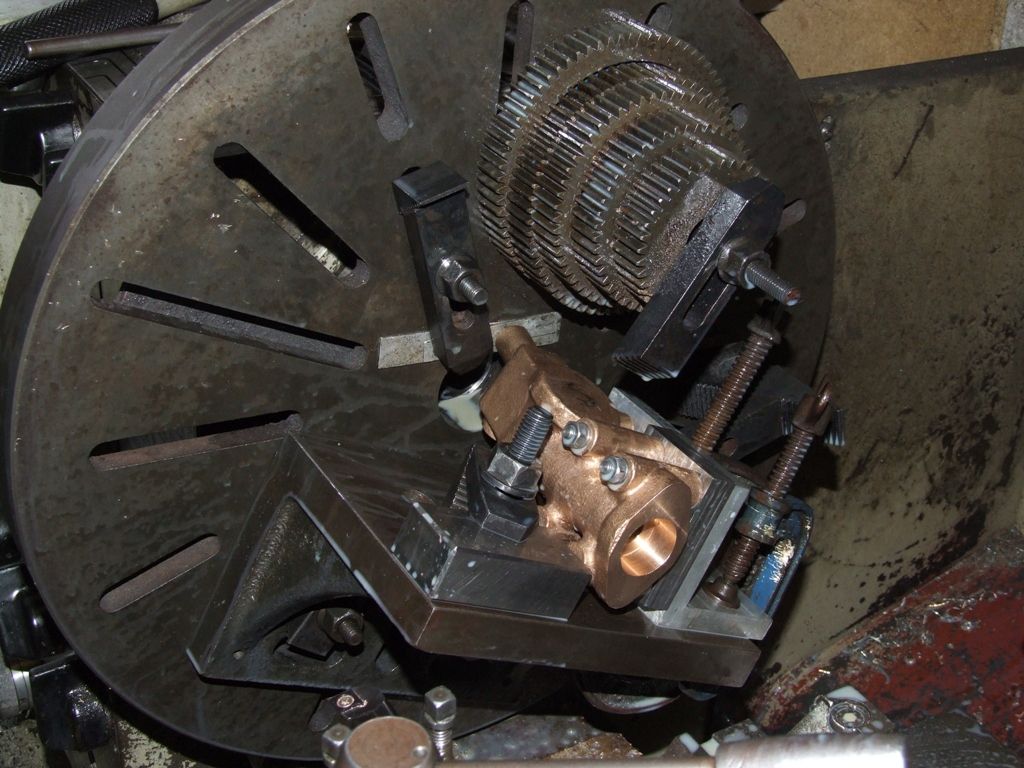

How I set the boring bar to cut the right radius in the job was to hold a disc on a bolt in the tailstock. The disc was the diameter of the scallop I wanted to cut out of the job. The job was marked up at the depth where the scallop was to go to, and was clamped to the f(l)aceprate so that point aligned with the edge of the disc held in the tailstock. Fortunately the diameter of the scallop was large enough that the job rotated around it with a space in the middle so did not foul. (Check this before pressing the start button!) The boring bar started off with light cuts and just kept going until the cut came out to the marked up line that had been aligned with the tailstock disc previously.

All a bit Heath Robinson but it got us out of a tight spot, having no mill or even boring head to use in the lathe. And it was suitably bizarre to provide an afternoon's entertainment.

I've since found that such flaceplatery works better for many jobs than trying to mount oversized objects on the spindly Myfrod double swivel vetical slide and trying to mill them. Especially with long or large jobs where the Drummond's limited four inches of cross slide travel restricts milling to that length, or actually less with a flycutter, whereas you can machine an 8 inch flat surface on the faceplate. And compared with the vertical slide, the faceplate is rock solid and some stupid large and oddball jobs can be done on it.

Next faceplate project planned is a couple of 4" x 4" angle plates. Turn up two cylinders with one end square to the OD, bolt them to the faceplate then clamp/bolt the angle plate (cut from thick 6" angle iron) to the two cylinders and face the surface. So many projects, so little shed time…

Edited By Hopper on 27/02/2018 10:27:23

Edited By Hopper on 27/02/2018 10:40:19

Hopper.