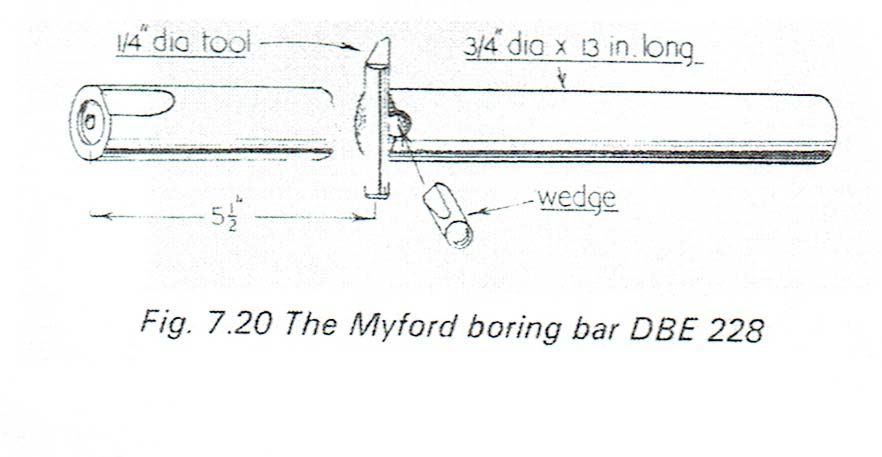

Here is an illustration from Bradley's Myford Series 7 Manual:

and some words of wisdom from ETW's 1951 ME Manual:

"In the simple type of cutter bar, the cutter is held by a grub screw or wedge, and radial adjustment is possible only by partial slackening off and tapping the cutter through. This is fairly satisfactory, except where a very close limit of dimensional accuracy is required; but in most cases where this method is employed, it is sufficient to machine the bore to as near the required size as possible, and fit any mating parts to it, such as cover spigots, piston, etc. Where high accuracy of bore size is important, however, it is possible to provide some means of fine adjustment to the cutter, though this is not so simple with small boring bars as with large ones."

Like Hopper, I made bars along the lines of GHT's design in which the cutter is not only screw-adjustable but directly restrained axially.

GHT was an exponent of the split cotter method put forward by John Haine but, apart from the limited "meat" available, there may be some advantage in grinding a flat on the cutter so that it maintains the same angle to the work after adjustment and gives a better chance of ending up with the bore to the desired size.

Edited By ega on 26/02/2021 11:48:10

Edited By ega on 26/02/2021 11:51:03

ega.