Posted by COLIN MARTIN 2 on 29/11/2019 10:04:00:

…I believe that the mini lathe lacks rigidity everywhere because it is quite poorly made and flimsy …

When comparing it to a bigger, studier lathe, which has so much rigidity in the head, bed and cross-slide, the mini lathe just has too much give in the components, so that the work tries to bend away from the parting tool.

…

Much truth in that, but it has to be said that many lathes struggle with parting off, and small ones are particularly troublesome. It's not that mini-lathes are exceptionally flimsy as such, rather that parting off is a severe test. Say a 2mm parting blade is used. The cutting edge is much larger than a point tool and bigger than average forces results. The parting tool operates in a slot liable to jam due to swarf or heat, and, if it dips for any reason, it's liable to dig in.

The forces applied by a 2mm cutter to a small lathe are the same as those applied to a bigger lathe : it's not surprising that big machines cope better.

But even big machines may not cope well with parting off. Anything allowing the cutting edge to dip will cause trouble. Worn beds allowing the saddle to rock, loose gibs (due to wear or maladjustment), not locking unused moving parts, excessive tool reach, jerky operator, bendy tool-post etc etc. Old Model Engineer magazines often discuss parting-off problems: no-one had a mini-lathe back then!

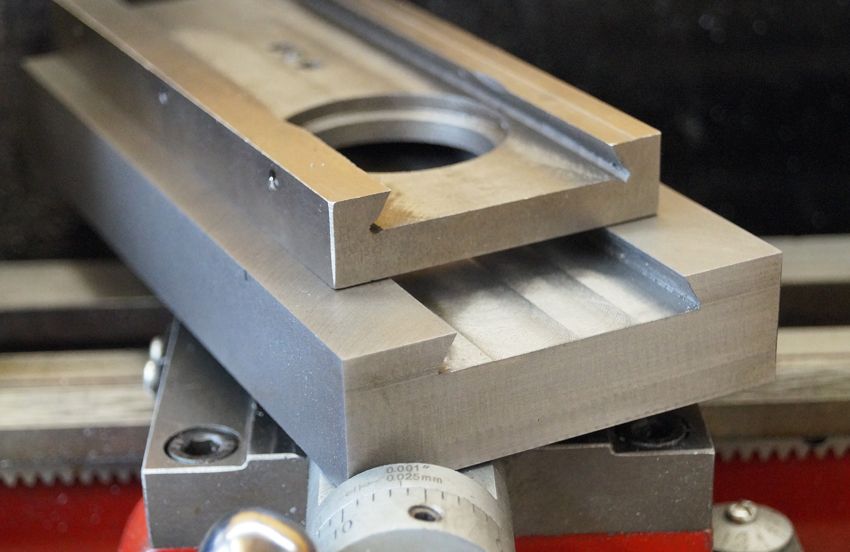

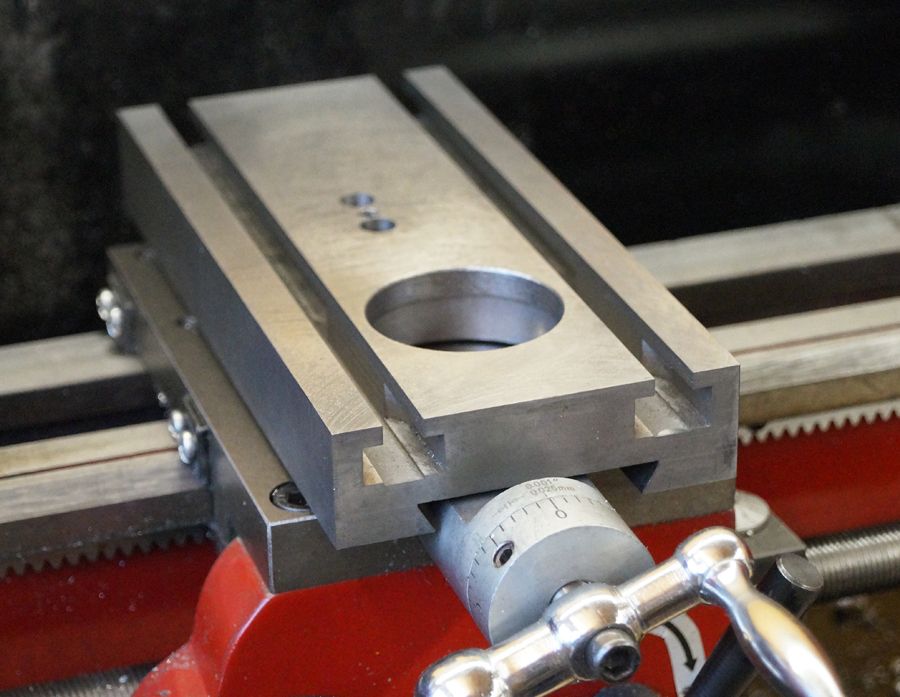

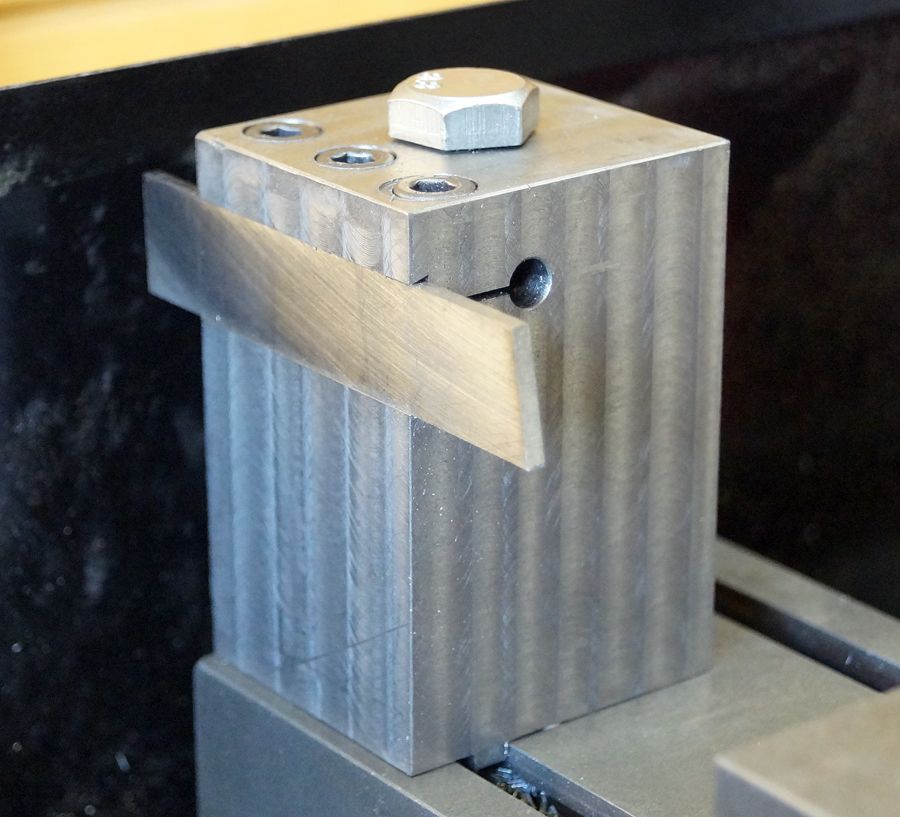

My WM280 can part off from the 4-way tool-post most of the time, but the cure-all is a hefty rear-mounted tool-post. The solid construction and position on the saddle of a rear tool-post enables any lathe to absorb significantly more force without dipping and vibration. Even so, it's still important to maintain a steady feed, to lubricate, and to clear swarf. I suspect a mini-lathe fitted with a rear tool-post would part off reasonably well, but fitting one means modifying the saddle. As space and the saddle design on a mini-lathe limits what can be done, not many are fitted with rear-tool posts!

I avoided parting off on my mini-lathe, preferring to remove the job to saw it, and then replacing to face-off. Wasted a bit of time, but a mostly suitable alternative. The lathe would part-off Brass OK, but Steel and Aluminium were more trouble than it was worth.

Dave

Niels Abildgaard.

…although, I had to drive to South Wales to collect it – around 250 miles round trip for me.

…although, I had to drive to South Wales to collect it – around 250 miles round trip for me.