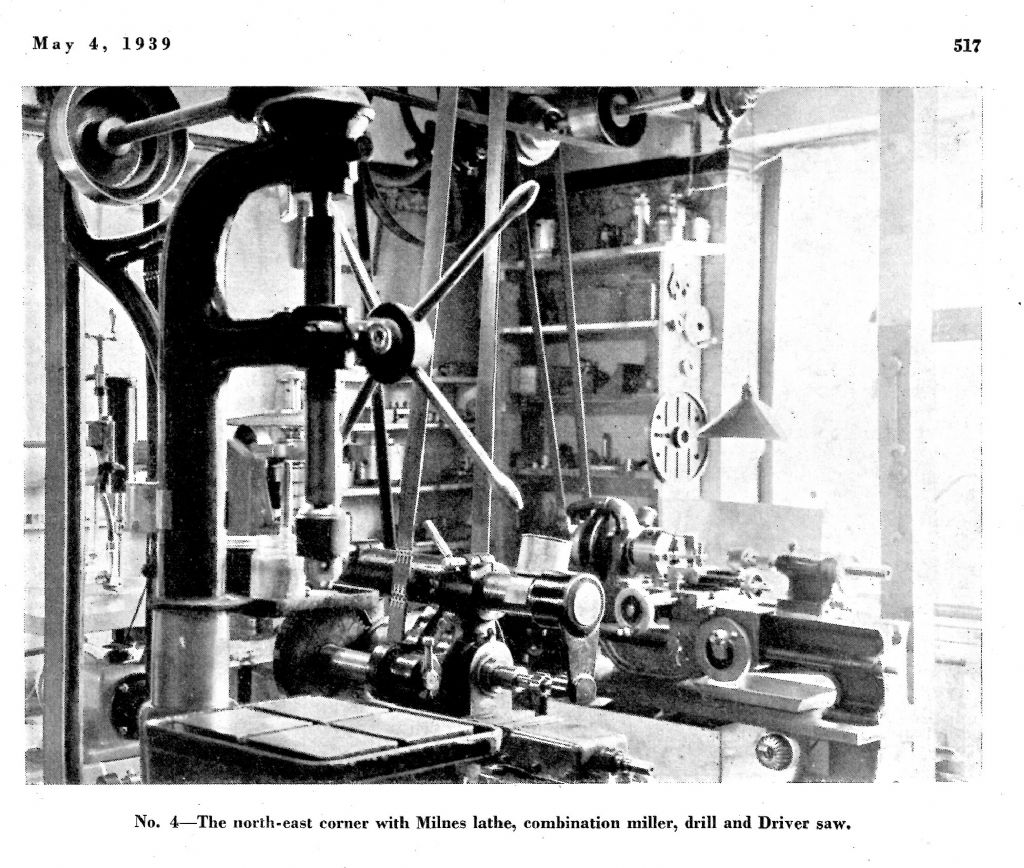

I run a Milnes type R lathe, and my lathe is shown on the lathes.co site under "Milnes type R". It's the second one in grey-blue paint with its original overhead countershaft. It is the standard bed length version, whereas the current Ebay ad looks like the long bed version.

I acquired mine about 9 years back and was very fortunate in that it was complete with a great deal of tooling, three and 4 jaw chucks, faceplate, driver plate, all its changewheels, (seemingly unused), overhead countershaft, bench and motor etc. etc. It was dirty and oil-soaked but had been little-used. The original frosting is still visible on the bed surfaces. It is a very accurate lathe for its age….headstock to tailstock alignment is excellent and taper on turned work is minimal. From advertisements in ME vols. from the 1920's and 1930's, my guess is that it dates from that era. My understanding is that Messrs. Milnes did not make the type R after about 1939.

I think it is a very fine machine for its time and still capable of very good work. LBSC ran one for many years. It was known as the "Rolls Royce of small lathes"…and I wouldn't dispute that.

OldMetaller.

8MAAOSw0AxZlLzq

8MAAOSw0AxZlLzq