To me when machined it has a surface much more like steel and not the slightly porus graphite rich surface of grey iron so probably less likely to be a good sliding surface that will hold some steam oil.

I've not machined anything from GS block or bar but have done several crankshaft castings, axle and various small parts and would not choose it over GR17. It is also not as nice to machine being more like steel and not a particularly free machining one. So to me the SG does not offer anything for cylinders but would be good for longer parts that you don't want to break.

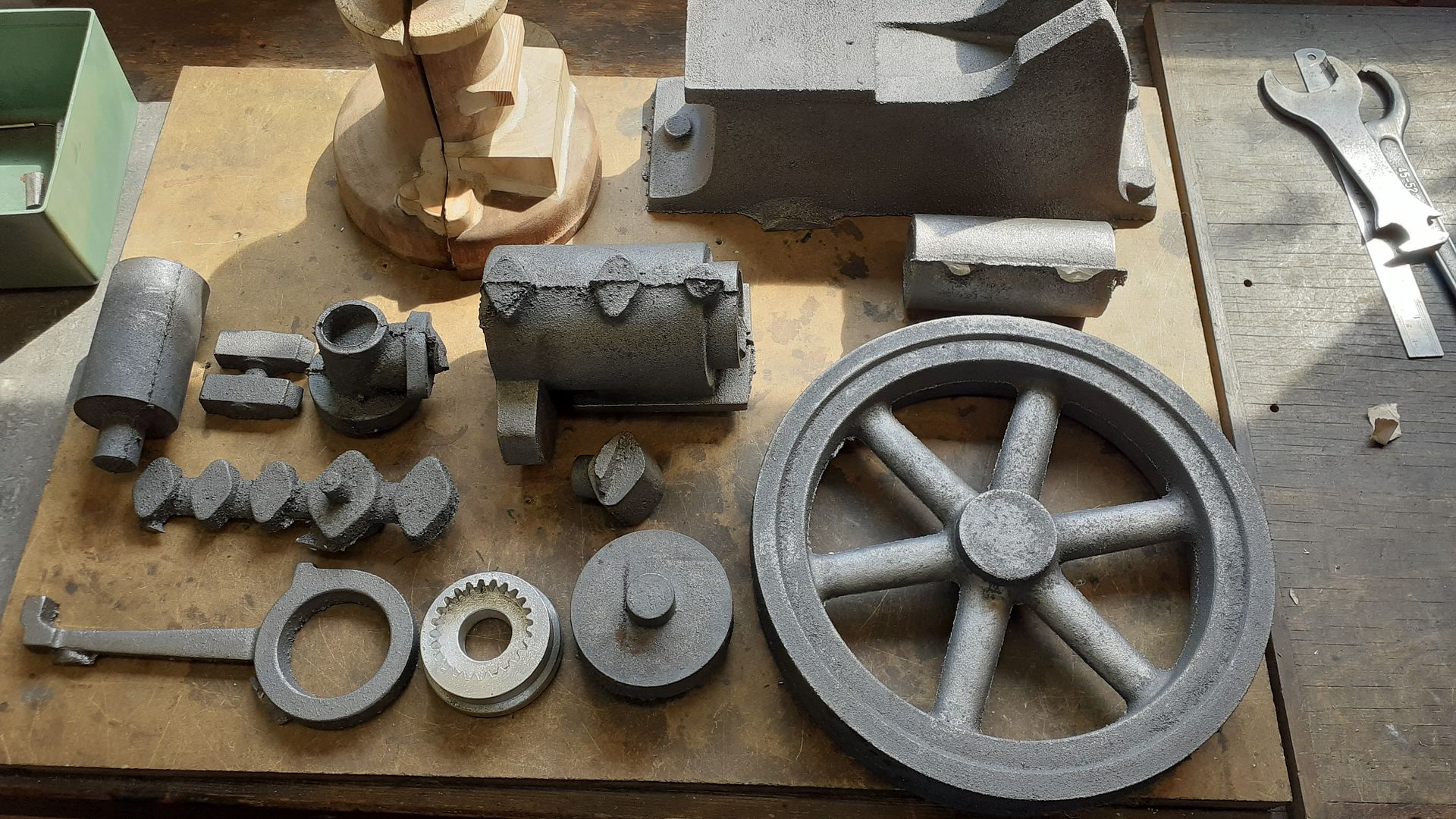

The Americans also use what they call ductile iron of which I've machined plenty of castings as they use it a lot on their hit & miss casting kits. This is somewhere between grey iron being similar to machine and the same sort of texture but is a bit less prone to fracturing than grey iron

Then there is the Smell which can put you off as SG has a nasty whiff about it when cut as does the American ductile iron.

Edited By JasonB on 16/08/2022 13:04:11

Edited By JasonB on 16/08/2022 13:05:12

duncan webster 1.