It's an interesting point Michael, a fully formed but undersize male thread will have thinner crests in contact with the female thread than one that has been cut from undersize material so I would expect the fully formed male thread to fail first.

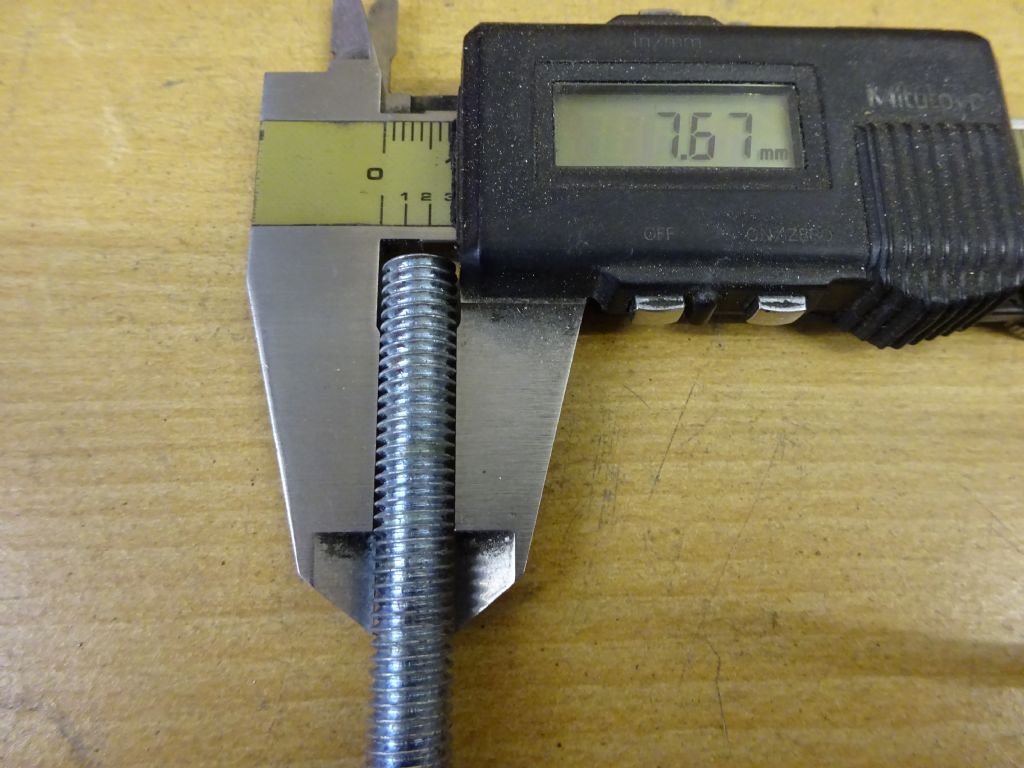

Anyway this is the stud I mentioned early on when I first enquired whether people who worked out percentage engagement bothered to measure the male thread.

M8 commercial studding, seems to have fully formed crests, rough almost torn surface and should we deduct the thickness of the plating

I also mentioned on about page two that I had seen undersize studding on which the crests looked more like an ACME form, I can't take a pic of that as it is now surrounded in 1/2 cubic meter of concrete holding up a clients tennis court post but here is a fine example of a rolled M10 thread with an OD of 9.32mm Proportionally that would be 7.46mm if M8

Proportionally that would be 7.46mm if M8

J

Edited By JasonB on 16/10/2016 08:20:40

Mark C.