I have been mulling over a suggestion I first mooted in 2013! It concerned the possible use of a mouse sensor as a device for producing an output to a display for use as a DRO for lathes, mills and the like. There have been a number of threads lately regarding the fitment of scales to, particularly, lathe cross slides and how they might restrict the movement of them and also interact with the chuck and/or tailstock. That set me off thinking, again. Always dangerous, but having a brief interlude in the metal-mangling, I thought – why not?

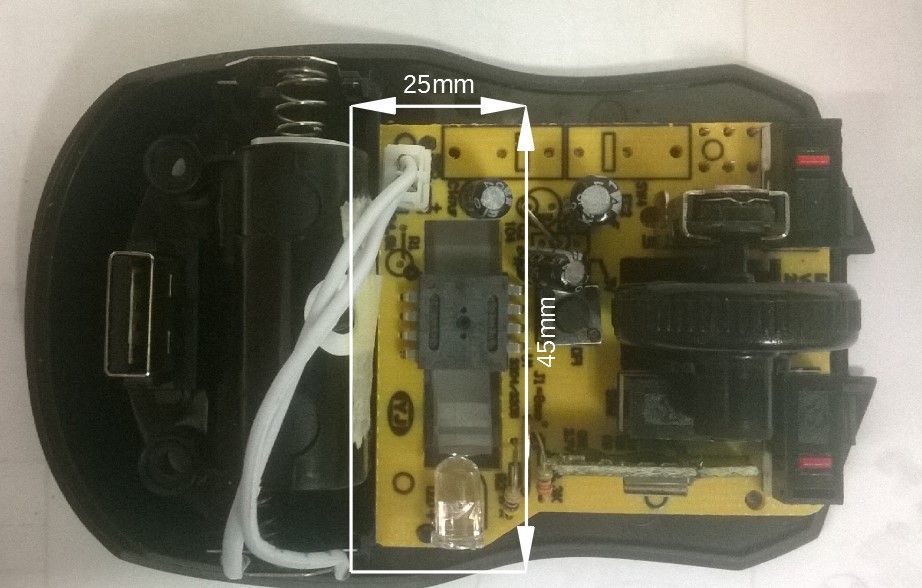

So I took an old mouse to pieces and had a look at the innards:

Not a laser mouse, but an LED one. I don't have one of the former. The rectangle indicates where I reckon the business end of the positioning electrickery is. Research has lead me to the conclusion that a laser sensor can detect movement changes of as little as 1 to 2 microns, better than my DRO glass scales, at 5µm. I therefore thought that if the sensor could be mounted in a suitable housing and secured to the cross slide, reading against an adjacent fixed part of the saddle, would it not be possible to utilise the bluetooth capabilities of a wireless mouse to communicate the output to a program running on a computer, tablet or phone in much the same way as Yury has done for the TouchDRO system? See Here.

Regrettably, I don't have the knowhow to implement the idea and write the necessary code to interpret the quadrature output into a meaningful display.

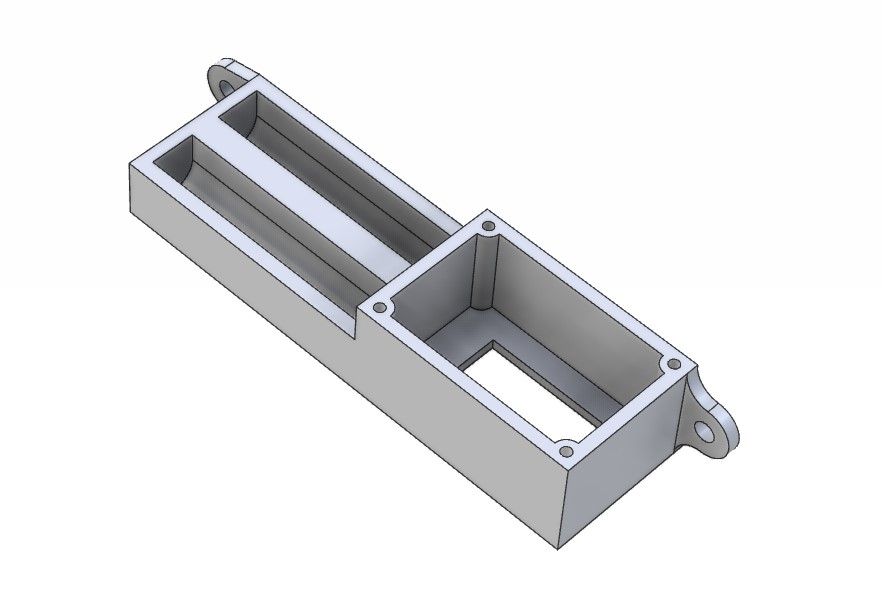

As we are in the tea room, feel free to discuss the merits or otherwise of this proposal. I have, at least, made a preliminary drawing of the sensor housing which I suggest could be 3D printed. It would need a cut-down version of the pcb designing, but I don't think that is beyond the wit of some of you on here.

The overall size of this would be in the region of 20mm x 30mm x 90mm long (plus mounting lugs).

What does the panel think?

John

Michael Gilligan.

Michael Gilligan.