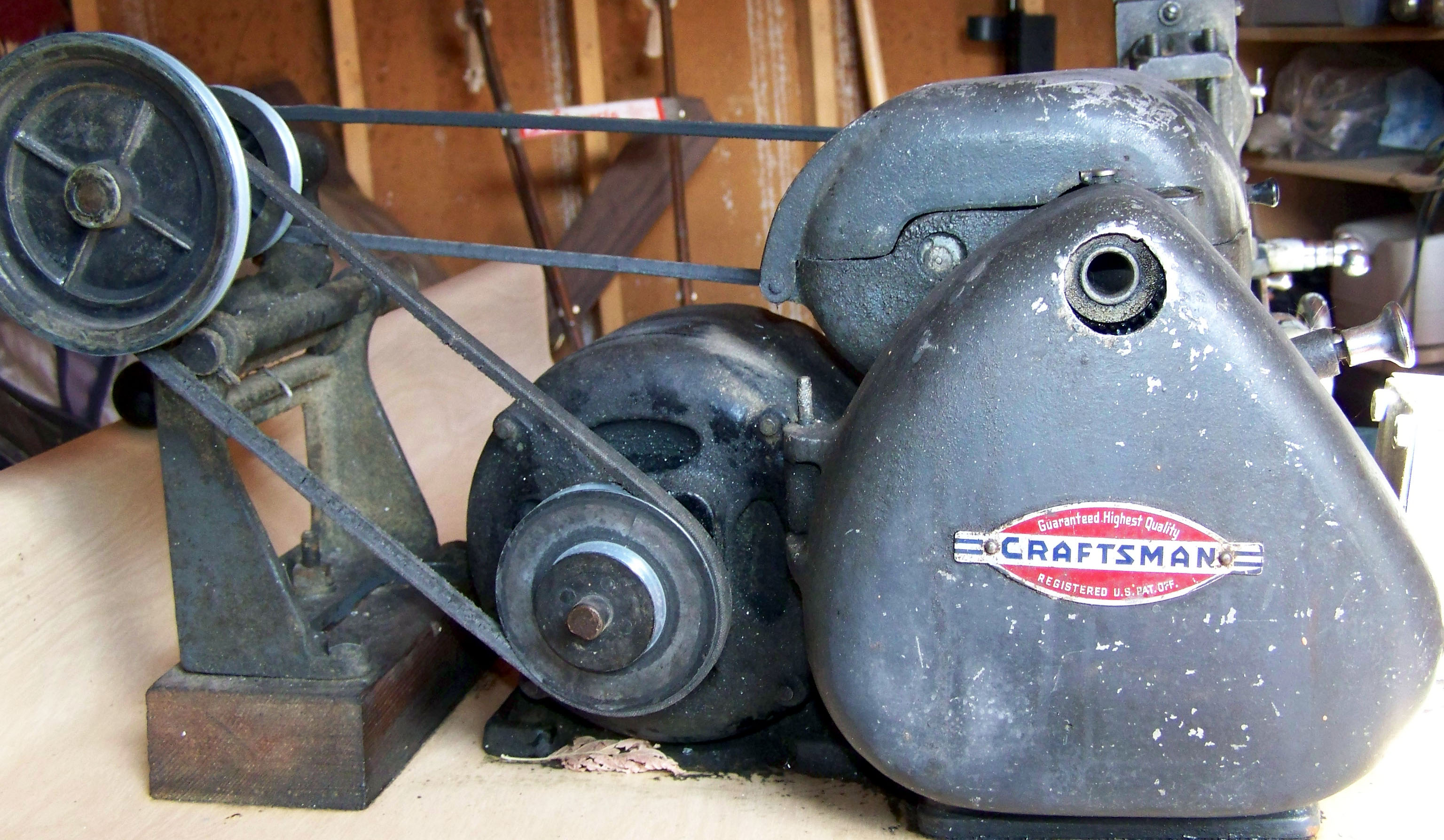

The lever on the back that locks the transmission is not to reverse, but most probably to engage back gear. the reason that everything locks is that you have effectively engaged two gears, of different ratios at the same time.

You need to find how to disengage the bull wheel (The gear that is locked to the pulley ) so that the drive can be pulley to small gear pinion, to large gear on back gear shaft thence to small gear on back gear shaft and back ton the bull wheel and mandrel..

Most probably a grubscrew in the bottom of one of the vees in the pulley.

Probably safest to remove the grubscrew completely and put it in a safe place, rather than leave it in and chance it being thrown out at some time when back gear is being used.

Back gear will reduce the speed of the mandrel by a factor of about 6, and provide extra torque.

It is a very useful feature when working, or screw cutting upto a shoulder, in that it gives you more time to disengage the feed, or stop the mandrel by slackening the belt. Saves a lot of damaged tools and workpieces, ,believe me!

The mechanism to reverse the feed, probably by the Leadscrew will be the tumbler reverse. This is two identical pinions, meshed together and mounted on a lever which allows one pinion to drive the geartrain directly, or when the lever is moved, via the second gear (Which acts as an Idler and so reverses the direction of rotation of the gear train relative to the mandrel.

My preference is for the "old fashioned" 4 way toolpost. Reputed to be more rigid that a QCT. Not having one, cannot confirm or deny. But the more rigid the tool set up, the better things will be from the point of surface finish and accuracy.

Biased, 'cos I have one at the front and another at the back!

For a lathe of that age, HSS would be my advice on tooling. You learn how to grind tools, is cheaper than carbide. (The lathe was designed before carbide tooling became common place, so will lack the speed and rigidity to get the best out of it. Intended for heavy industrial machines where time is money )

My favourite HSS tool is the Tangential Turning Tool, either home made, (MEW has published at least two designs, in the past ) or the Diamond tool from Eccentric Engineering. With only one face to grind, sharpening is quick and easy.

A 1/4" toolbit cost about the same as a carbide insert and will outlast a single carbide insert. Plus, as I keep saying, you can regrind at 8:00 on a Saturday night, when a chipped carbide tip ceases to be of any use.

Before anyone complains of ignorant bias, I also use carbide tips, for roughing, boring and screwcutting!

The "escapement type arrangement" looks to be a detent for indexing, using a changewheel to provide the means of dividing.j

HTH

Howard

James Tregaskis.