Nice jobs Wayne

Some years ago I used a combination of Stuarts indexing peg idea and the X-axis DRO on my Bridgeport milling machine to produce lines of holes 4 inches apart on two 14 ft long 2 inch square tubes and four 2" x 3" (nominal) timbers of similar length. These were to be the hinge carriers of a large 9 ft high x 14 ft long American style horizontally hinged, vertical opening, bifold garage door. The 26 1/2" X-axis travel of the power feed Bridgeport let me do 5 holes at a setting.

Although the process worked well enough it was not as fast as I'd anticipated and handling the large, quite heavy, overhang as I got towards the end was not trivial. Anticipating the possibility of overhung jobs I'd designed my workshop so the secondary door and milling machine were placed so as to allow long jobs to project over the vegetable plot! But I'd not anticipated something that far overhung!

Although acceptable for a one (OK, four !) off job I'd not consider that type of method acceptable for commercial or regular use. The inevitably short table of a 2 axis cross slide would make handling long materials even harder than it was on my mill. One job was quite enough thank you.

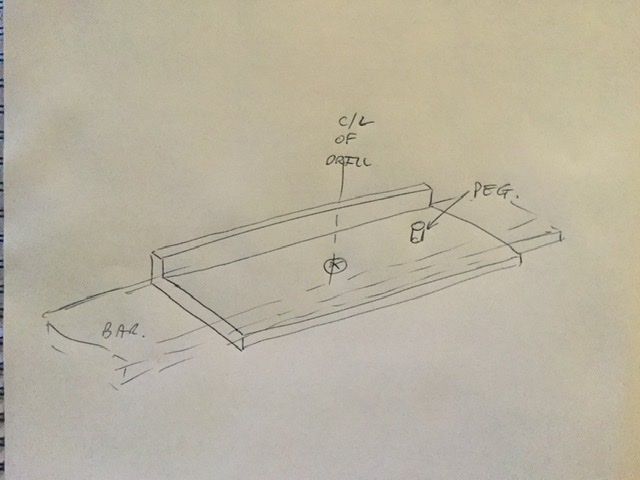

If I ever do that type of job again I shall make a specialist "rail-bench" long enough to hold the complete part with a suitable indexing guide, either integrated or bolt on, and use a magnetic drill to make the holes. Maybe an RSJ or steel box section on legs for the bench. Mag drill running on spring loaded wheels so its easy to shift along. A fixed chain makes an effective indexing system if the link spacing happens to work right.

My door.

Hope this helps.

Clive

Edited By Clive Foster on 06/02/2022 16:41:21

Wayne Rowley.

![dsc_1120[1].jpg dsc_1120[1].jpg](/wp-content/uploads/sites/4/images/member_albums/201824/904179.jpg)

![dsc_1248[1].jpg dsc_1248[1].jpg](/wp-content/uploads/sites/4/images/member_albums/201824/904176.jpg)