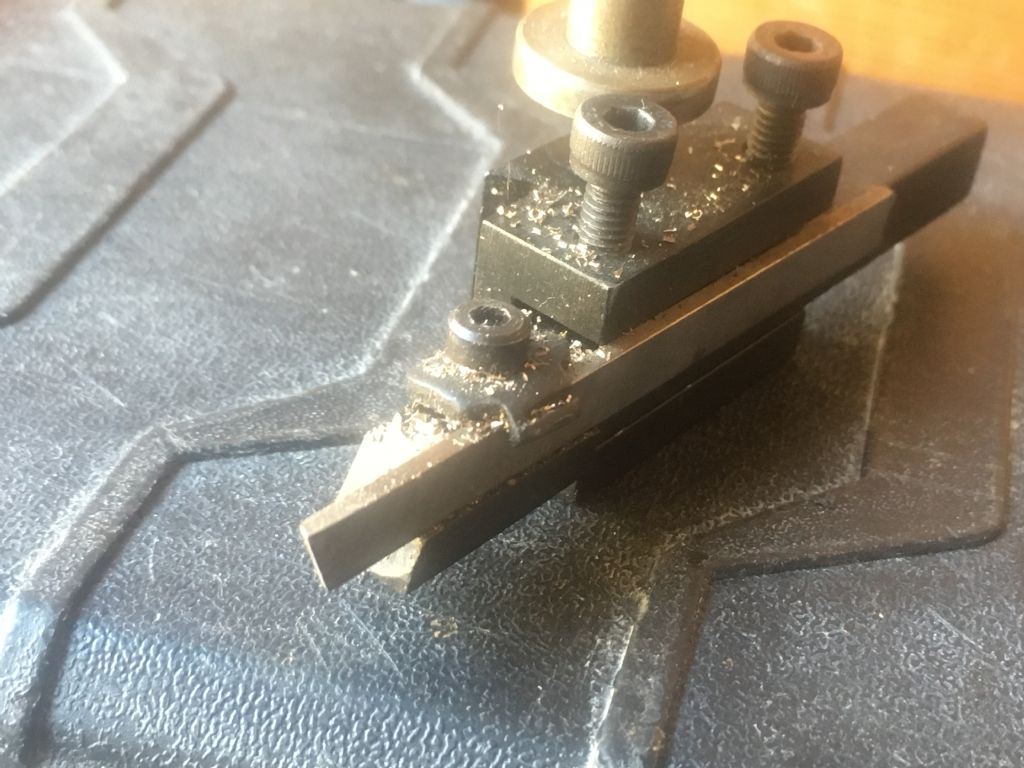

On enlarging the pic it looks as though the 1.5 mm blade is dull / has a radius on the cutting edge which is where I assume you mean …'

…'gave a slight hone, which didn't help a great deal'…

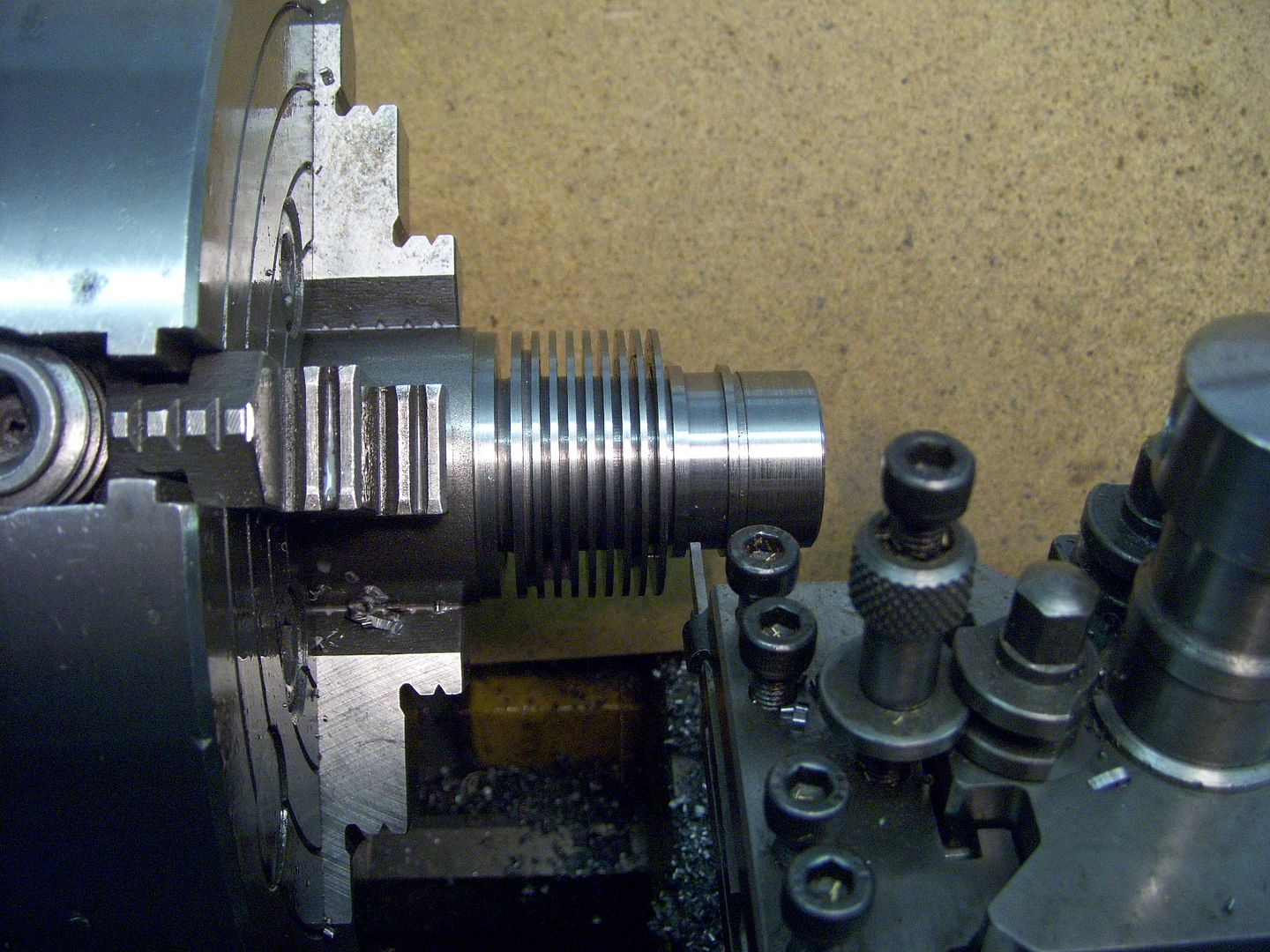

It needs to be really sharp on the tip otherwise you are 'rubbing' rather than cutting. I assume that you have the tip dead on centre height ( no insult intended ) otherwise you will be 'rubbing' just under the tip if the tool height is high, conversely if the tool height is 'low' then the tool will be 'dragged under' as the work tries to climb over the tool tip… broken tool / work / both.

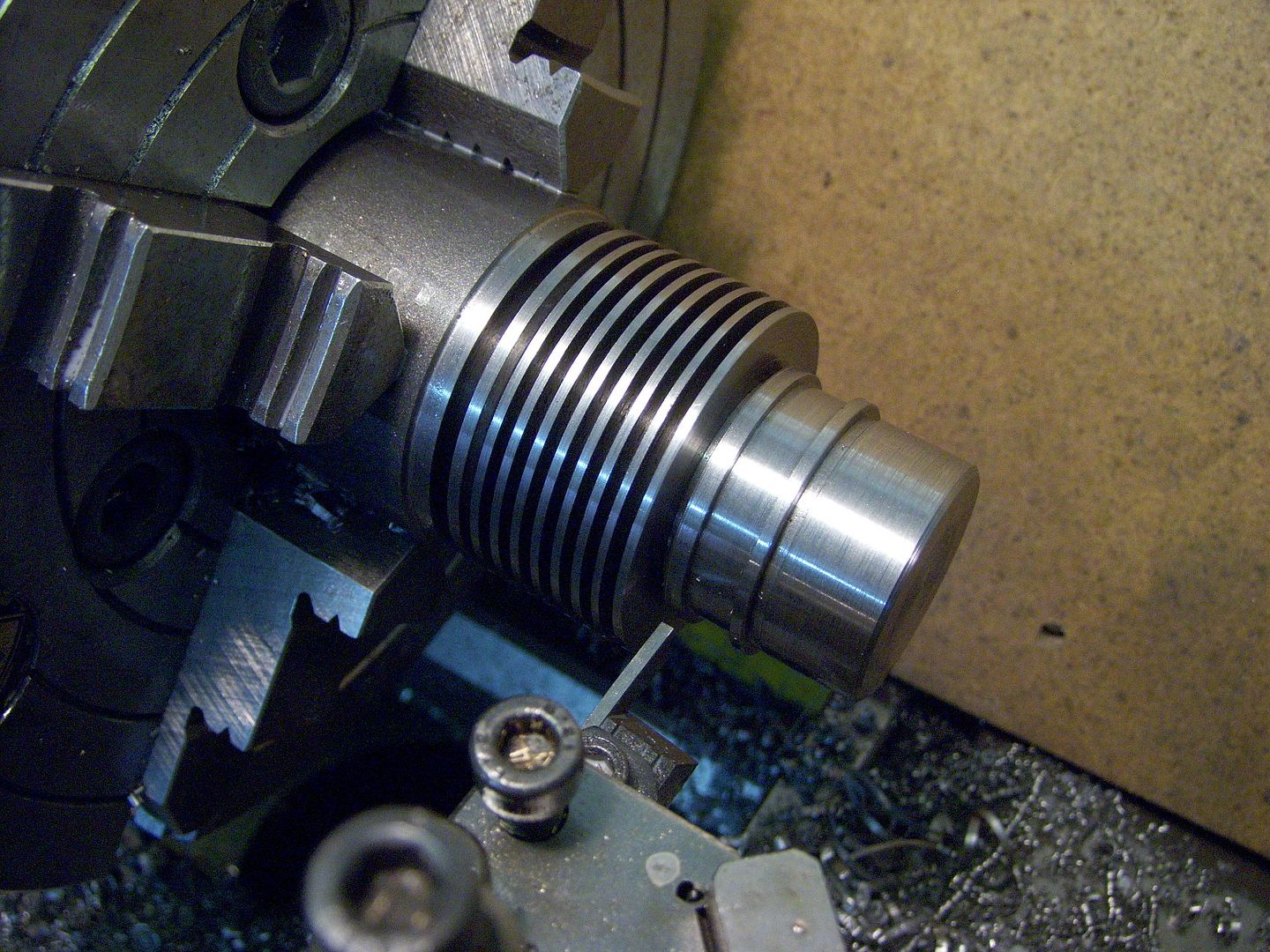

Once you start to 'cut' continue to feed the tool in at a steady feed, iirc your machine is too small to have a power x feed so you will be feeding in by hand, keep it steady & constant & you'll be ok. As with all of us at some time or other we have been frightened by parting off, gingerly feeding in then immediately withdrawing the tool as soon as it chatters, don't! keep the in feed going, with practice you'll soon get to 'feel' the cutting action & know when to increase / decrease the in feed.

As for lubrication…

Brass / Cast iron … dry.

MS & other ferrous material… Neat cutting oil or similar applied with brush works fine, ( for me )

Aluminium… WD40 does fine for me, other members use a variety of mixes so…

Enjoy

George.

Howard Lewis.