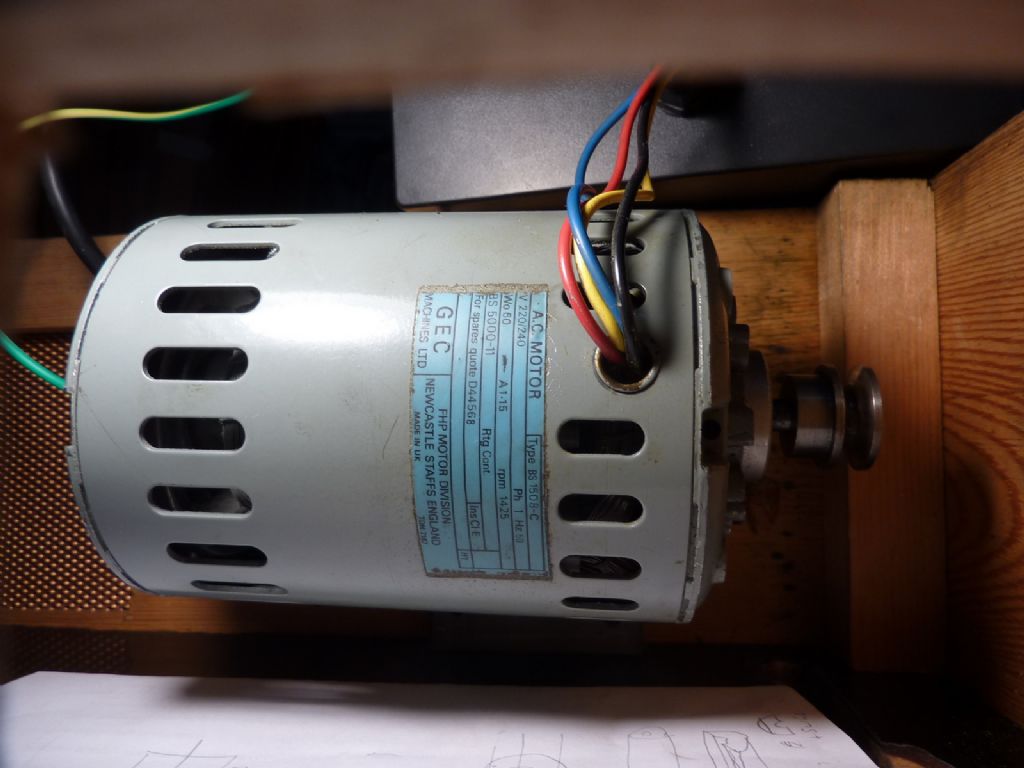

This single phase AC motor (see photos) was supplied with Cowells lathes in the late 1970s (and perhaps later).

The motor is GEC 'type BS 1508-C, 1425 rpm, for spares quote D44568' if anyone wants the blurb from the sticker.

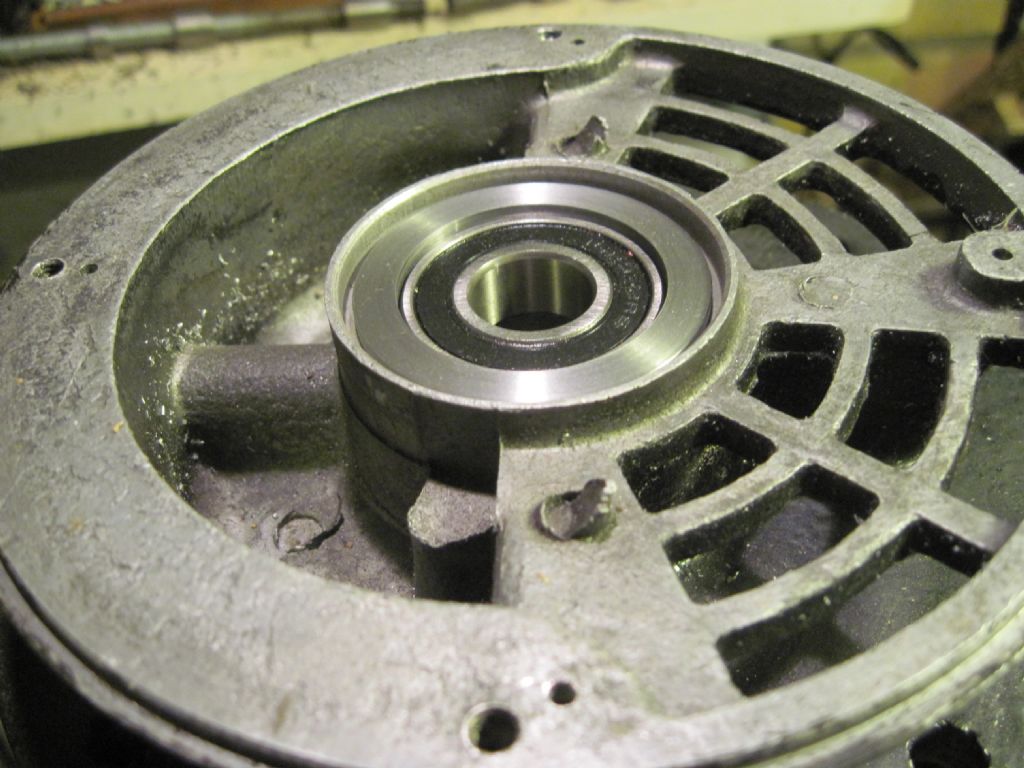

The bearings appear to be worn sufficiently for the rotor to rub on the stator when the drive belt to the lathe is not tight.

I'd like to replace them but how to get them out is not clear to me. I'm hoping that someone here has successfully done something similar.

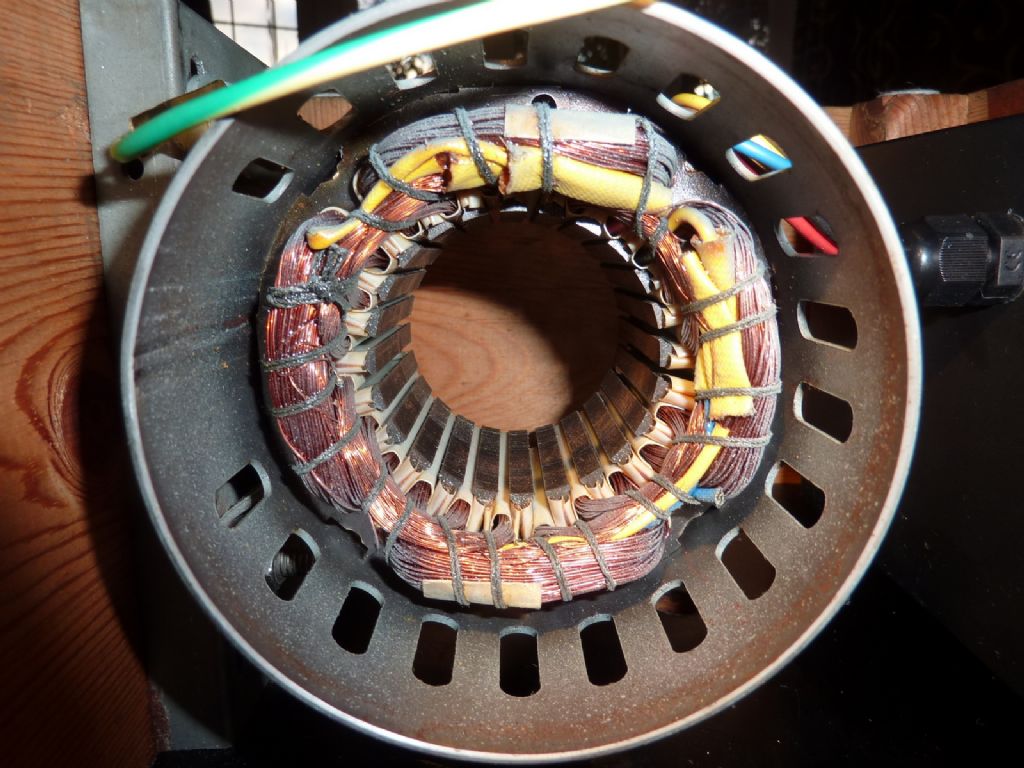

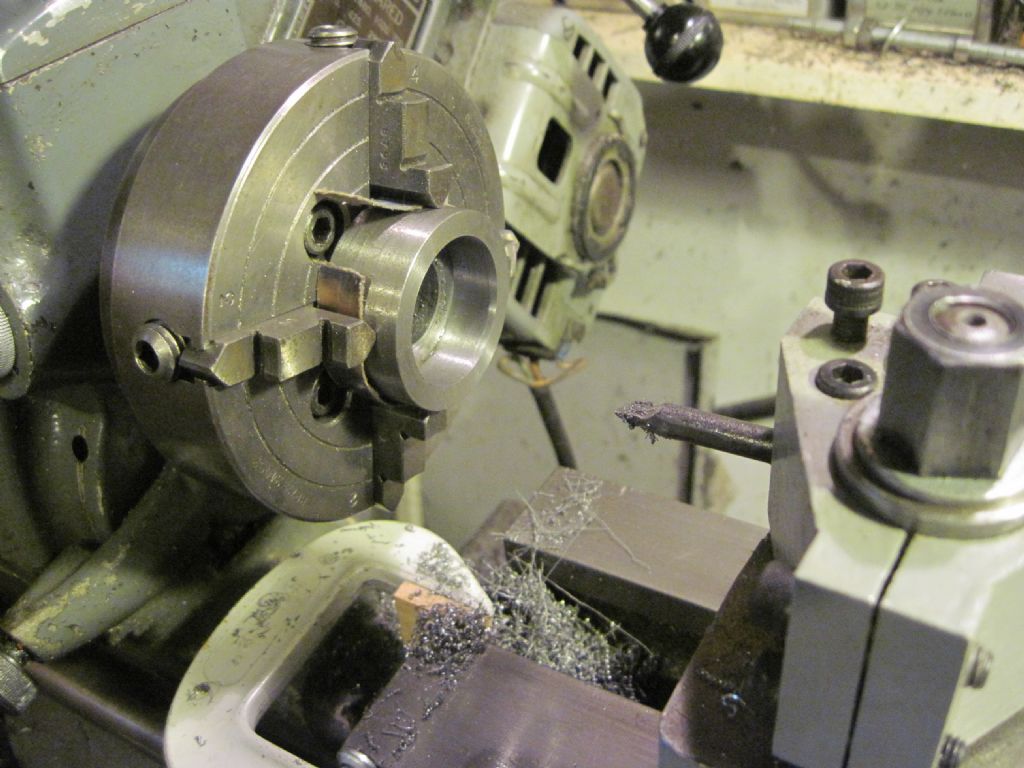

The motor seems to be a pretty simple affair with no slip rings or commutator involved. The alloy ends house the bearings and are secured by two (2BA?) threaded rods that go right through the casing. With the nuts undone it is easy to take off the ends and pull out the rotor.

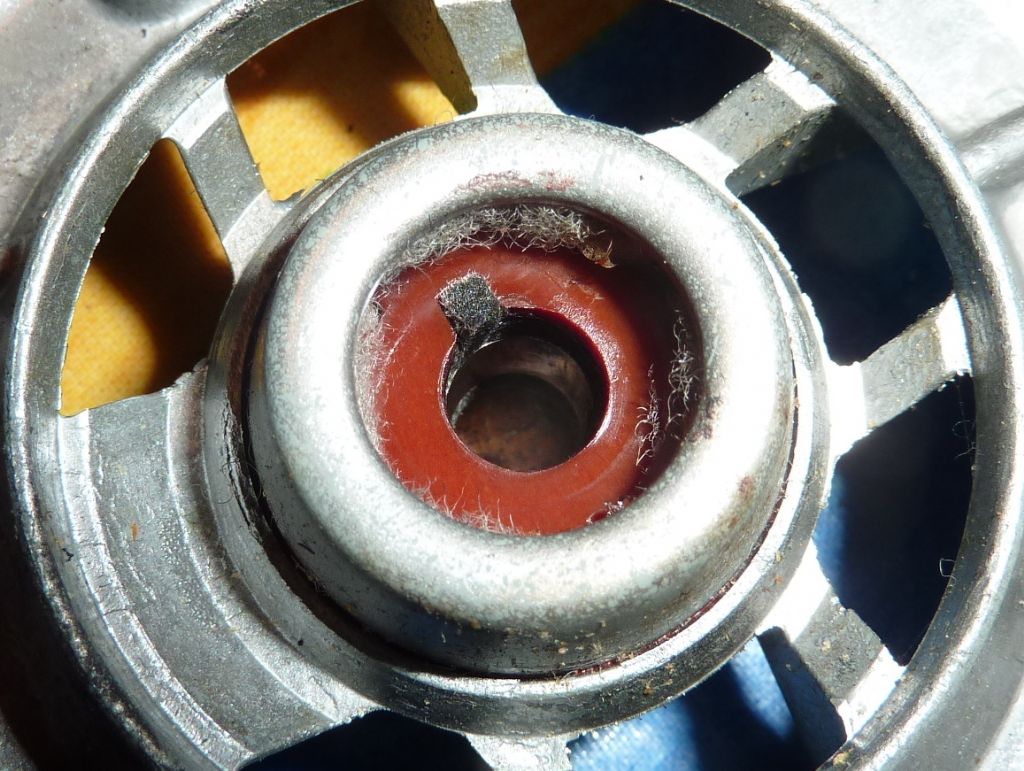

The bearings seem to be plain (bronze I guess) but they are enclosed by what look like pressed steel caps both on the outside and inside ends. There seems to be some wicking material surrounding them and a wick in contact with the motor shaft. The shaft has a spiral groove presumably to persuade the oil into the bearings. A (tufnol?) part surrounds the shaft inside the end caps on the 'indoors' end.

Can anyone advise on how to get the bearing housings apart without causing damage please?

I suspect that a previous owner has turned one of the ends through 180 degrees such that the unworn side of the bearing takes the load of the drive belt. This does stop the rotor from rubbing on the stator as long as the belt is tight but it can still make grating noises when starting and I'm not happy with it as a long term answer.

Thanks.

Andy

Phil Whitley.