Posted by Oily Rag on 20/06/2020 10:41:18:

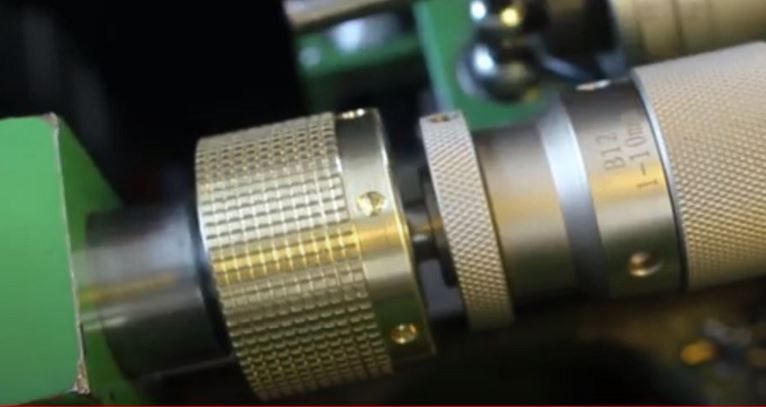

A good video and some excellent workmanship in creating this tool. However, although the tool is of an interesting design, it appears to be overly complex, and in that I refer to the provision of 'azimuth displacement' effected by the roll of the head by using a ball bearing / pad design. The axial displacement is all that one 'should' need unless the lathe is hopelessly out of alignment.

The use of the chuck also puts a lot of mass outboard of the flexible joint – notice the drop of the reamer as it exits the hole. Surely the use of single split collets allows for a simpler design and a lower mass of the moving parts. A very simple and effective design is the old Buck & Hickman model 20BA.

Overall a very nice machining job though, congratulations!

I have noticed some angular alignment issues in my set up with reamer/drills deflecting as they enter a previously drilled hole, so I included the ball to try and address this. I did wonder whether the mass of a chuck would be detrimental, approaching this as a hobbyist I thought it was worth a try, the tool was an experiment and for sure could be improved.

I based my design upon a commercial product I was shown some time ago which was just as "floppy" as my design and I was told it had some angular freedom of movement as well as radial. While I didn't get the finer detail of it's design this is my best guess how it worked as far as I can fathom, my design achieves, as best as I can, the same result as the commercial one I was shown.

You got me thinking and it would be possible to move the pivot point in front og the taper on the collar/chuck carrier, the tool works very well for what I want so I'm not inclined to spend any more time on it.

Other than the one I was shown I'm not familiar with any other designs and didn't look into it, my aim was to replicate the commercial one I was shown and saw working.

Thanks for some interesting feedback.

Nigel

GoCreate.