Posted by William Ayerst on 29/10/2020 09:09:16:

Friend of mine is going to build me a bench out of welded steel box section to my spec, i.e. size/height with mounting holes for the lathe on crossmembers and a galvanised steel drip tray for £240 delivered in primer.

Much simpler!

Can you share the design William?

Designing a stand to take the weight on an ML7 is trivially easy, the devil is in achieving rigidity and stability. If you're going to spend £240 on making a bench, it makes sense to confirm the design is fit for purpose. I'm wondering if someone who has to ask about benches is well-placed to design one from scratch?

Benches aren't rocket science, but people tend to focus on weight without worrying enough about top heavy lathes on a tall narrow stand being dangerously easy to topple over, or the possibility legs might scissor, or the need to stop the top deflecting whilst minimising shake and vibration.

Here's a Victorian treadle lathe. Flimsy stand, only suitable for low power, slow speed and carbon-steel tools. Not very stressed and the bed girder is part of the structure. OK in it's day, but times change.

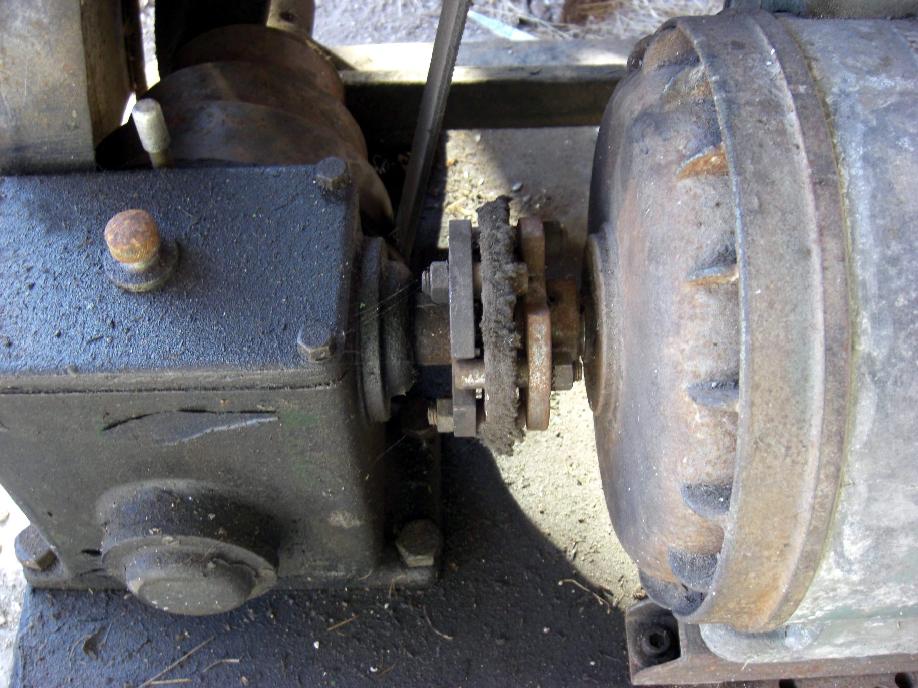

The treadle design isn't up to a motor and HSS cutters; the whole thing vibrates when pushed hard. The next generation of lathes went for heavy cast-iron bases:

Although cast-iron is cheap and effective as a machine tool material, it makes the tool heavy and awkward to transport. And although cast-iron looks strong, it's weak in tension and brittle. Easily damaged.

Next improvement was towards strength and rigidity achieved by clever design rather than simply by pouring more cast-iron. Steel frames, box structures, welding etc. Done properly, they are stronger, cheaper and more robust than cast-iron. The change led to modern lathes (designed after about 1940) to be slimmed down so the lathe bed isn't part of the weight bearing structure, as taken to an extreme by the arch in the example above. These lathes are intended to sit on solid stands rather than be part of it, reducing cost and improving accuracy, This Colchester sits on boxes.

Big lathes come up to operator height fairly naturally with a low centre of gravity. Smaller lathes have to be lifted up on a stand to about elbow height, resulting in a high centre of gravity, making them prone to wobble and toppling. Worth confirming the proposed stand ticks the right boxes before building it!

Dave

Pete..

Pete..