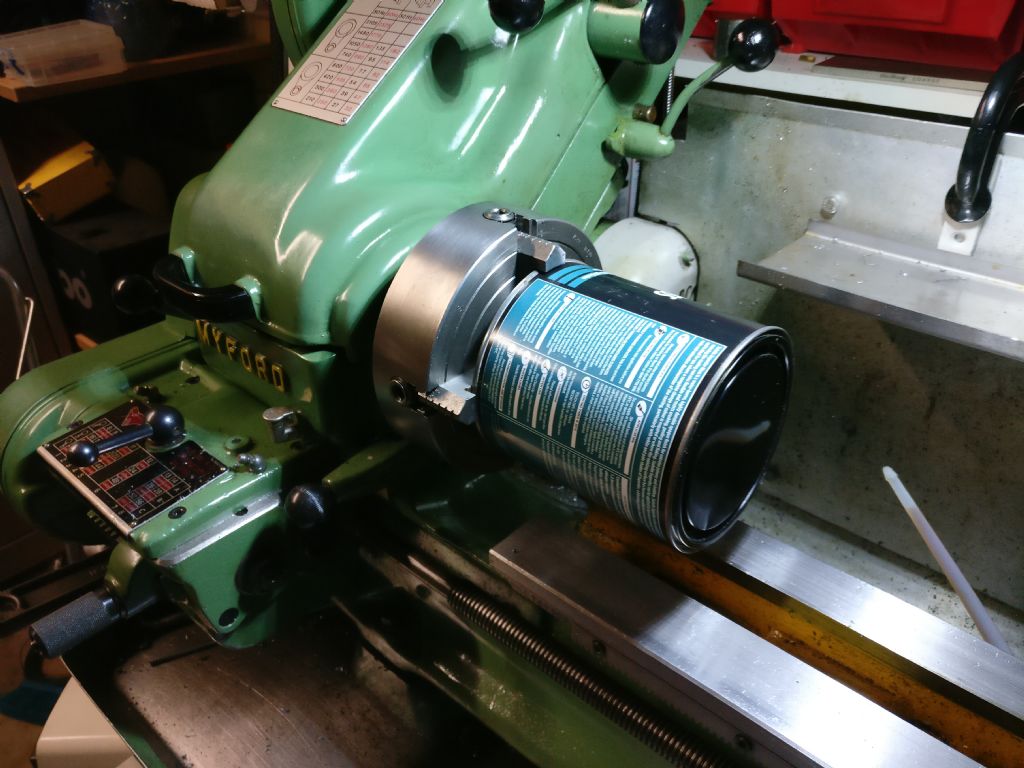

I really can't see the point of a 6" 4-jaw on a 3 1/2" centre lathe without a gap bed.

Compare capacities on internal and external jaws, using the jaws at least 50% engaged for the Zither slim body chucks (p.s. the 4.5kg was for a slim body chuck):

6" – 3" on internal jaws, 5.5" on external jaws.

5" – 3" on internal jaws, 5.5" on external jaws.

4" – 2.6" on internal jaws, 3.5" on internal jaws.

So while a 5" chuck offers a gain over the 4", the 6" offers no benefit over the 5".

If you accept the 'minimum two threads engaged' rule the capacity of the 4" on its internal jaws becomes a bit over 3", that's MORE than the 4"or 5" chucks!

On this basis the capacity of the 4" chuck's external jaws is about 4.2".

So if you want maximum capacity, get the 5" not the 6". The extra cost of the 6" gains you absolutely nothing.

If you want almost all the capacity and the benefit of holding larger work securely in the inside jaws, get the 4".

THIS DOES NOT APPLY TO A GAP BED MYFORD BUT THE OP HAS A NON-GAP-BED LATHE!

Neil Wyatt.

Neil Wyatt.

chucks.

chucks. chucks.

chucks.