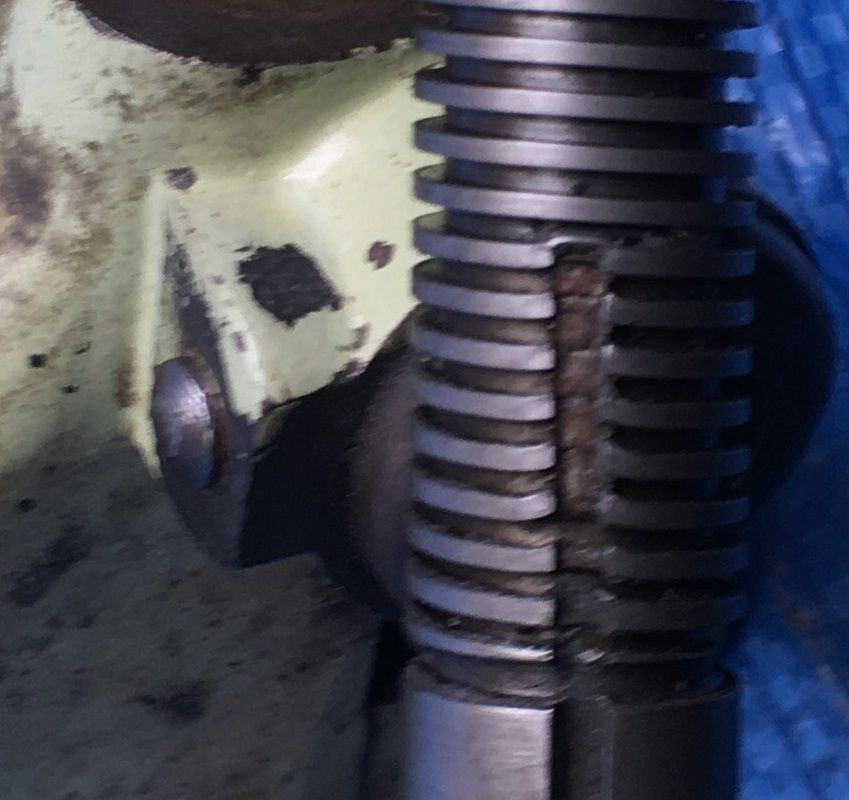

Just had a look at my M-type and refreshed my memory from when I rebuilt the tailstock years ago.

There is a tiny 1/8" grub screw that holds that key in place. The grubscrew descends vertically down from the top of the tailstock casting, directly above the key. Original probably had a screwdriver slot in the grub screw, I replaced mine with a allen type grub screw, so must have been 1/8 BSW (or more likely UNC that will fit right in.)

Once you scrape the 25 layers of paint off the tailstock right above the key you should be able to see the grub screw and either screw it out or drill it out.

The the key can be tapped inwards until it falls out. Dont tap it outwards as the mashed end will score the hole in the tailstock.

The key is a piece of 1/4" round bar with the end machined down into a tang that fits into the slot in the tailstock quill. The tang is the width of the slot, minus a thou or so clearance, and it runs across the full width of the 1/4" diameter bar. I made mine by filing down the end of a piece of bar to suit.

Will try and take a pic with my phone and post it shortly.

Howard Lewis.