(1) The discussion is about drill chucks for holding large drills not drills of 1/2 in or below .

(2) The holding shank part of a reduced section drill is very unlikely to break certainly but that is not the point at issue .

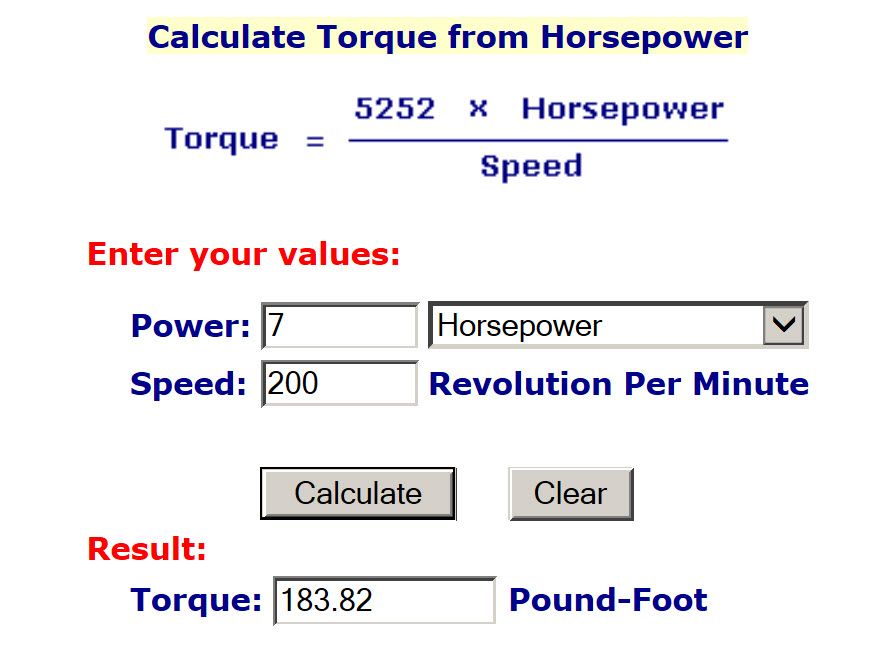

Its about gripping the thing well enough to carry what can be an enormous torque .

If shank and cutting diameter are something like the same there is not usually much problem but if shank gets to be less than about 0.6 times cutting diameter it will begin to slip under higher loading unless chuck is done up abnormally tightly .

(3)Purely out of interest the torque in a normal twist drill is carried by the whole cross section not just the core .

A few additional thoughts :

(1) There is a reasonable limit to the size of drill that any particular machine can handle . In the case of drilling machines the socket size is usually a good indication . For instance 2MT has a limit of about 5/8 in properly maybe stretched to about 3/4 in for lighter use .

(2) When drilling specifically in a lathe there is sometimes merit in mounting drills on the carriage rather than on tailstock .

They used to do this years ago , then the practice was forgotten , but now it has come back again with some CNC machines .

A lathe I had years ago had no tailstock . I made a simple drill chuck mount to go on the cross slide and used it very successfully .

(3) There are better ways of drilling big holes than using big twist drills – have a look at some modern drilling technolgy with inserted tip tooling .

Michael Williams .

Ian S C.

..

..