Posted by Neil Wyatt on 23/05/2016 19:08:44:

Posted by Georgineer on 23/05/2016 14:49:34:

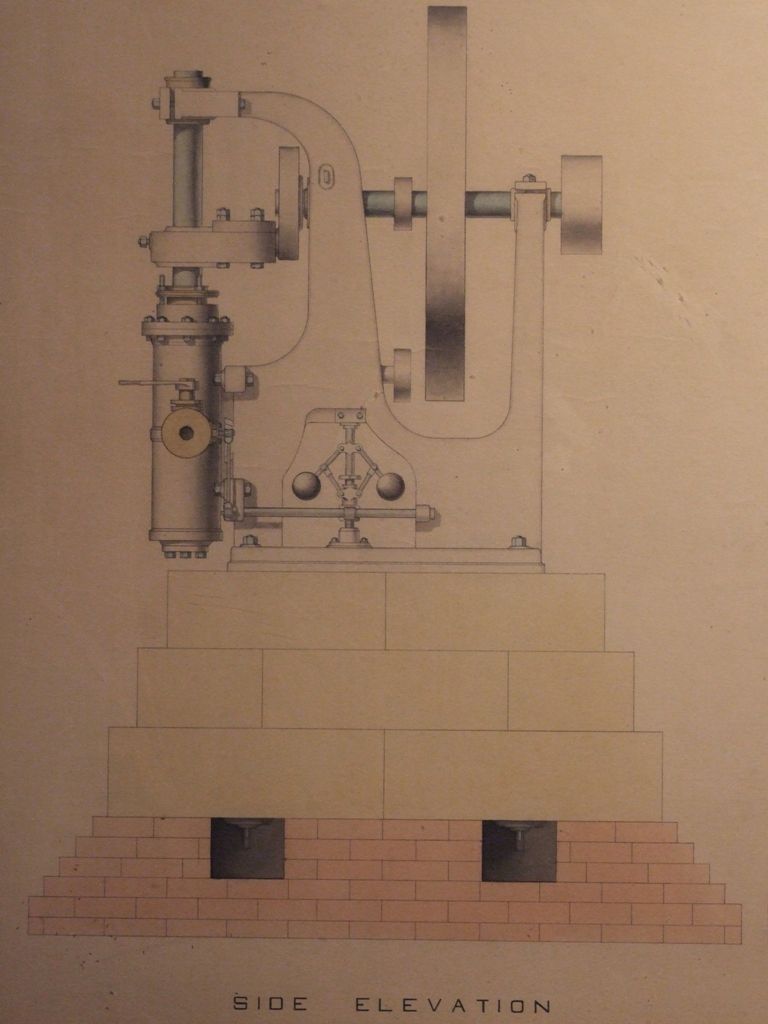

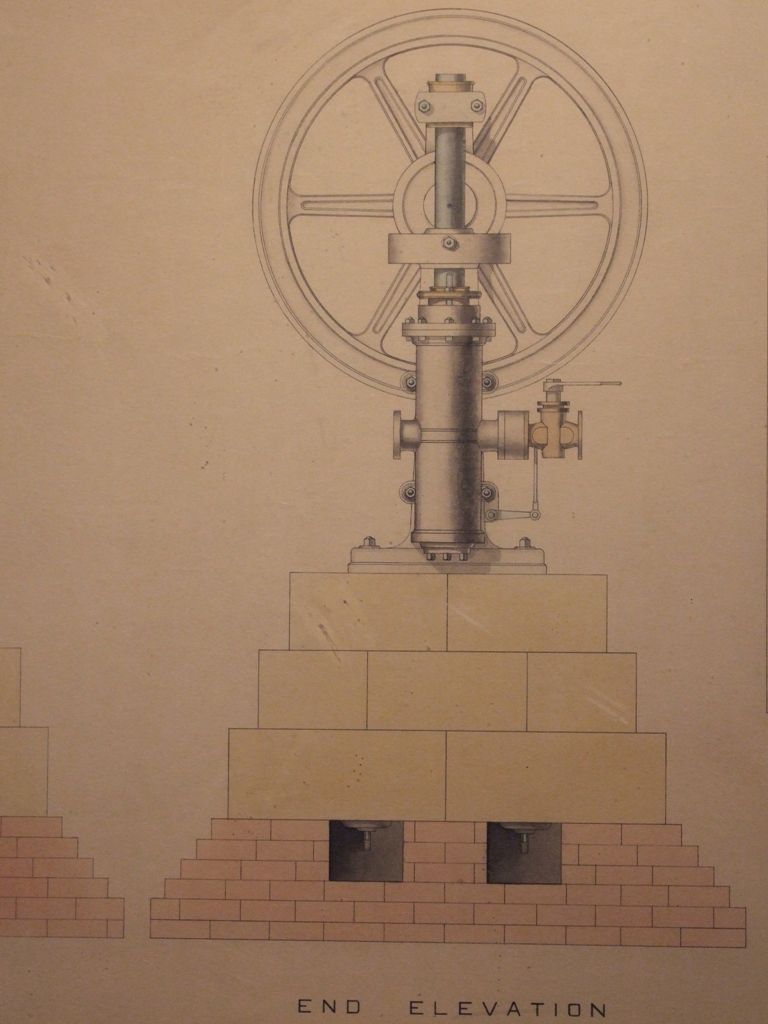

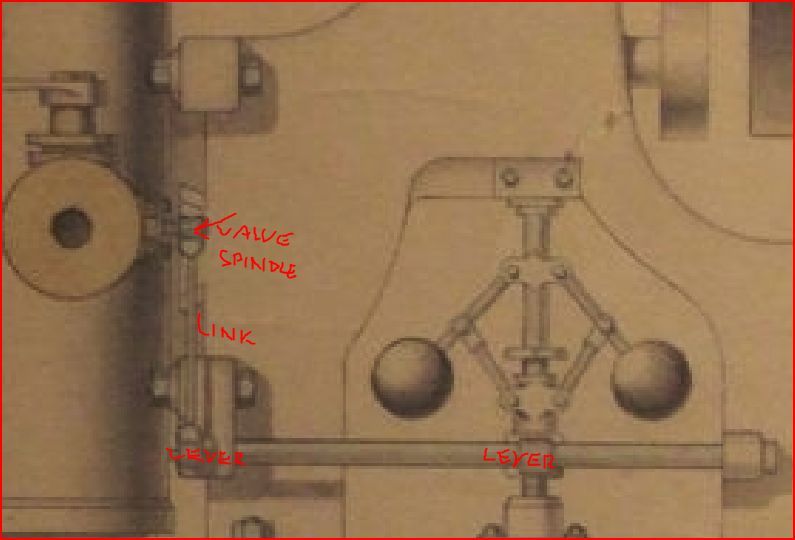

Here's an exercise drawn in ink on linen by my mother as an 18 year old tracer in HMS Vernon (Portsmouth) in 1936. I still have the pen and compasses she used.

What a fantastic keepsake!

Is it a trigger horn off of a sea mine?

Googled this a bit – mines used chemical triggers, so is it a torpedo fuse?

Neil

Edited By Neil Wyatt on 23/05/2016 19:15:38

This drawing reminded me of something I read somewhere, and the strange workings of my memory finally retrieved it this morning as being from Norman Friedman's "Naval Weapons of World War One".

It's a Hydrostatic Switch from a mine, not a horn. It's main purpose is to activate the mine after it's been laid.

This type of mine is anchored to the seabed by a kind of winch and cable arrangement that sets the operating depth. This could be as deep as 100m to catch submarines, but more usually would be just too deep to be set off by passing fishing boats. Mines do not float on the surface.

In storage the top of the switch is sealed with a soluble pad. The mine is safe until this pad has been slowly dissolved by seawater, by which time the mine layer should be well away. The outer top cap is pulled off just before the mine is dropped into the sea.

Once the pad has dissolved seawater can enter the innards of the switch to press on the diaphragm. At operating depth the piston is pushed sufficient against the spring to make an electrical connection between the two lower bolts. This brings a battery into the firing circuit and activates the mine. After that bumping a horn will set it off.

A secondary purpose of the switch is to make the mine less dangerous should it accidentally come adrift. Randomly drifting mines are dangerous to everyone. If the cable breaks the mine floats to the surface. With luck removing pressure from the piston will disconnect the battery, making the mine "safe". I say "with luck" because after several months in the water corrosion or sea-life might have jambed the mechanism.

Friedman reproduces a drawing on Page 361 of a complete British EC II mine that includes one of these devices. On the drawing it's labelled "Hyd Switch Mark III" .

The drawing in the book isn't as good as that traced by Georgineer's mum. Well done her!

Cheers

Dave

JasonB.

JasonB.