Thank you all for your replies, they are much appreciated.

Emgee – Yes I expect you are right, they probably are too tall for the BCA. More than likely I'll be using the dividing head on the lathe. I can (and have!) used the rotary table for dividing, but as you say there's always the "other" plane.

Thor – Yes, I never thought of lowering the centre height. Maybe make a riser block for use on the lathe in order to match the lathe's centre height?

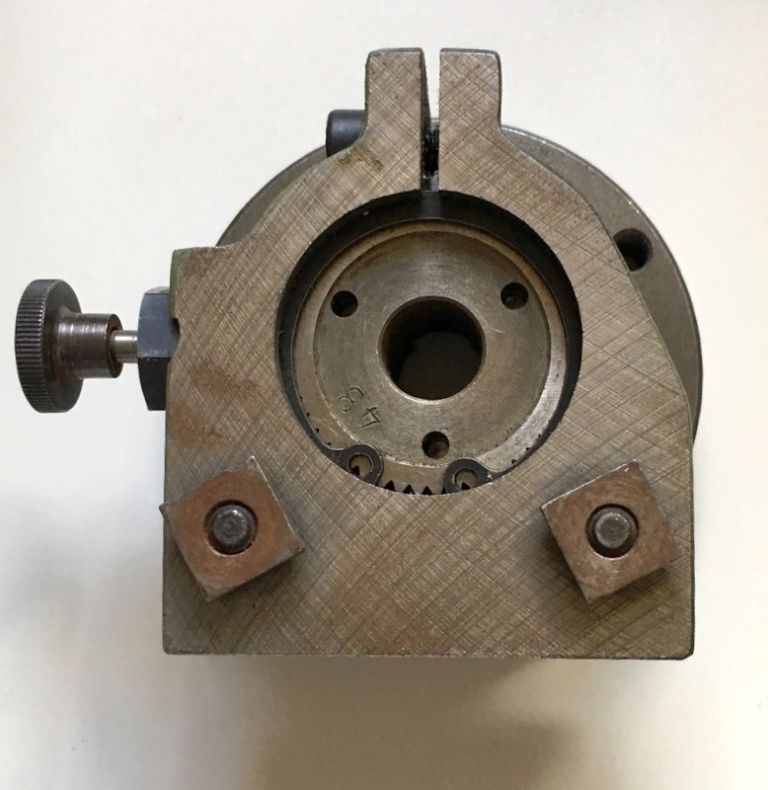

Mick Henshall – Thank you for the photos. I find it interesting that the dividing head is clamped to the bed, but still appears to be at centre height with your engraving tool (which also appears to be the HH design). Does that mean that your dividing head sits above the spindle height if used on the crosslide?

Bazyle – As I have an ML7, the GHT castings are at the correct centre height anyway. So from that perspective there's no difference to the HH design. I quite agree on matching the nose to my lathe, I have no reason not to.

Phil P – I remember seeing your Sigma(?) and your dividing head on that "other" forum…. Very nicely done!

Ian T – I've seen someone else post up their Timmins, it looks like it fits the bill. I couldn't find much information on that website though?

One other thing, and again this is probably just me being dense….. The basic GHT kit from Hemingway comes with just a 24T wheel for simple indexing. I appreciate that 24T provides many of the common divisions, but it appears that any other number of divisions requires the full index plate + worm arrangement. Is that correct? The HH design, on the other hand, allows the index wheel (gear) to be easily swapped as required.

Mick Henshall.