Posted by SillyOldDuffer 17/01/2021 10:41:32

Be careful repurposing second-hand pressure vessels because their pressure ratings aren't guaranteed. In particular disposable bottles are lightly

made because they don't have to withstand the repeated inflations and deflations that cause metal fatigue.

Rechargeable pressure vessels are stronger and have a limited life after which they are withdrawn before they become dangerous.

As always level of risk depends on the circumstances. Occasional recharging of a small second-hand bottle at reduced pressure in a home workshop

is much safer than repeated recharging to full pressure of a large time-expired bottle in a busy factory.

As a matter of interest, does anyone know what happens when an old bottle fails? Copper boilers as used on 'our' steam locomotives leak and split

rather than explode because the copper and joints both give way gradually. Steel is much stronger than Copper but likely to shatter. So although steel

vessels hold a lot more pressure they fail in a blink and the pent up energy is released all at once in an actual explosion. I vaguely remember reading

gas cylinders are weakened at the neck so the top blows off and they vent upwards. This in expectation they are stored vertically bottom down and

can't take off like a rocket.

Anyone tried doing a hydraulic test on an old disposable gas bottle to see how safe they actually are? Harder to test than a locomotive because gas

pressures are higher, for example Propane about 200psi and Carbon Dioxide 900psi. Argon could be at 3500 psi.#

Dave

# This implies it's safer to repurpose an Argon cylinder for reduced pressure work than one that contained propane!

————-

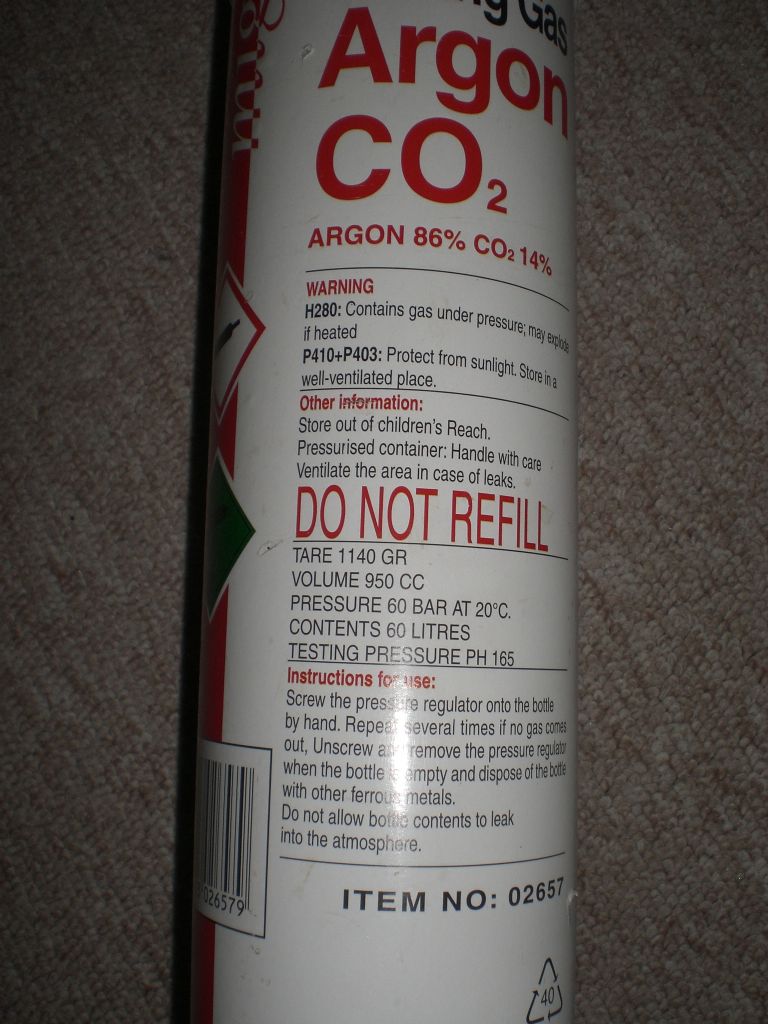

The Bottles mentioned in my last post have a maximum rated pressure of 165 bar

2,400 psi ,i would not consider these to be lightly made ,if you cut one

open the wall thickness is at least 3/32 inch or greater.

Pressure of propane gas at 20 deg C is 7 to 9 bar.

Of course if you happen to live in Death Valley you would need to observe that the gas

pressure would increase ie at 50 deg C is 15 to 19 bar.

Less for butane however at 50 deg C butane pressure rises to 3 to 7 bar, 103 psi,

the throw away camping gas containers that butane is supplied in is 0.017 inch

wall thickness.

Air line pressure used in these mig containers is about 115 psi .

Unless you make a pig's ear of soldering on the fittings these things are no less

safe than using copper for the pipework or even plastic and it is as well

to point out the the the supplied air tank with the compressor is a great deal

thinner than these mig bottles.

When the first model gas turbines were sold by JPX in France

these run on propane and used an aluminium container as a fuel tank a

similar size to the mig gas type bottles but very much thinner ,having had

the opportunity to repair one of these engines and examine these parts

the container for the gas was so thin you could easily press in the

sides when empty.

John

Peter Sansom.

.

.