I have finally managed to acquire a Cromwell S800. What a delight – though I now appreciate the warning Mr Wootton gave me regarding the peculiar controls. Lets see if I can manage to retrain my aging brain . . .

As might be expected after all these years the machine isn't still completely original and now benefits (I think) from a more modern variable speed drive system. Presumably one of the 3ph jobs so popular among users nowadays. I was expecting big things re the statements made about "no loss of torque at low speeds' etc.

Some picture attached may or may not help. Not easy getting anything decent in the gloom of the garage today.

Sure enough it runs much more quietly than my clunky S7 but I was surprised that it could not manage more than a 5 thou cut in steel without slipping. My preferred solution – turn up the speed and crank the cutter in a bit further to kill or cure the problem, well, killed it. Machine stopped running – providing a reason to pop off the panels and dig around. The problem is pretty obvious but I would appreciate some guidance before I commit to a solution. I am mindful that there are far better brains than mine on this forum.

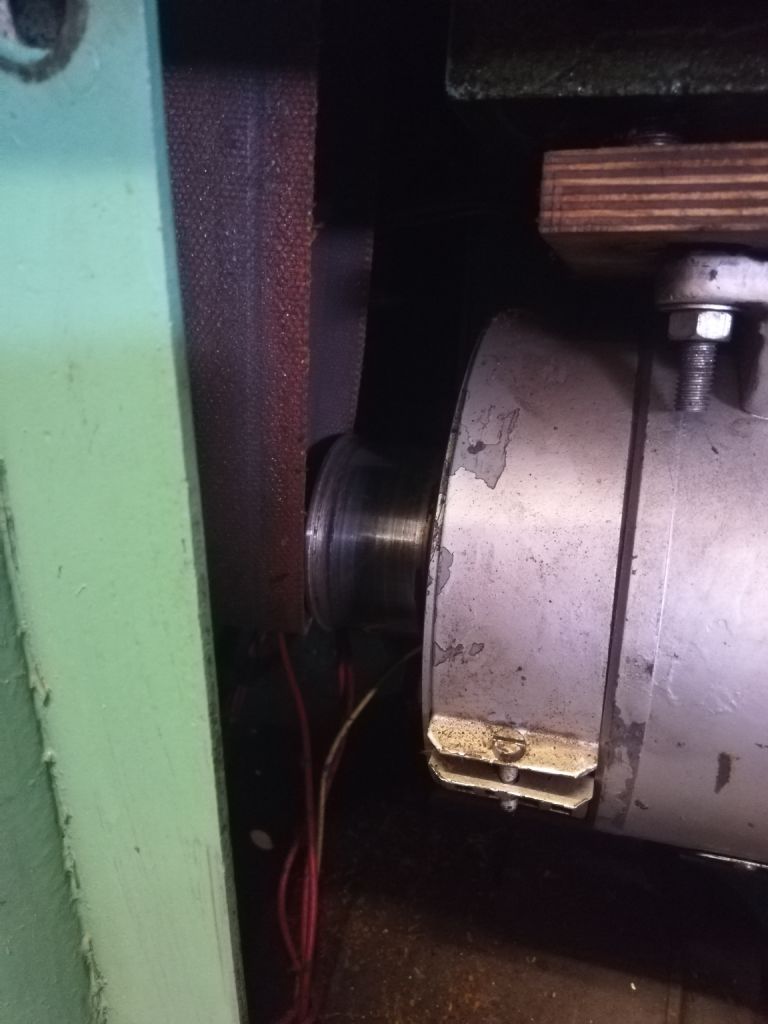

The big motor in the picture (silverish colour) looks to have the right size drive pully and looks to me to be basically aligned with the relevant section of the spindle. It is clear that when power is applied and the belt tensioner is tweaked there is enough slack in the system to allow the belt to work itself loose. This is where I request a 'best' solution from the forum.

The motor itself is mounted on a piece of plywood that is past its prime but basically sound. That piece of plywood is thence mounted on the original mounting plate of the machine drive. At least one of the bolts holding the plywood to the original mount has come adrift allow a 1/4" or so of play/wobble up and down and back to front in the system. Presumably that is enough to allow the flat belt to walk off the end of the pulley notwithstanding the 1/8" flange on the end.

In a perfect world someone with more experience than me will simply say "replace the missing bolt or bolts between plywood and base plate and double check all other fixings are secure and all will be well."

Alternatively this is a lash up waiting to cause a bigger problem so maybe I need to do more? What additional things should I be looking for? What would the absolute best solution be?

I am not going to change the motor. It runs fine but I very much doubt it is the original.

Are there alignment considerations between the motor pulley and the headstock drive shaft over and above the obvious one that they align in the vertical plane?

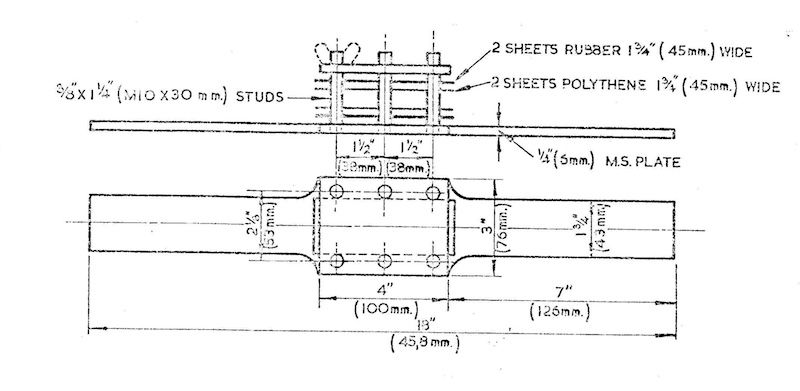

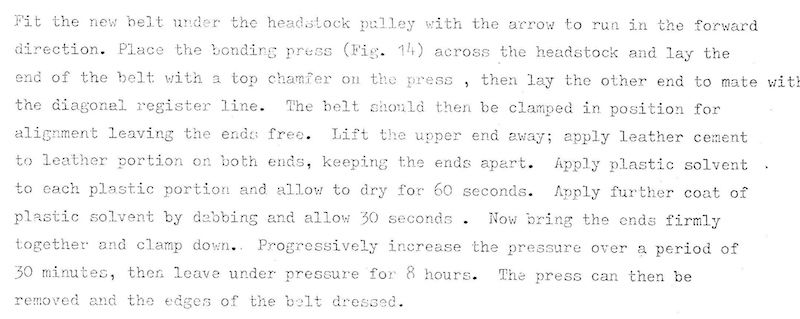

The drive belt is the old 1" variety with a pinned connection. Is it worth changing that as a belt and braces job after securing the motor more thoroughly?

Any assistance gratefully received.

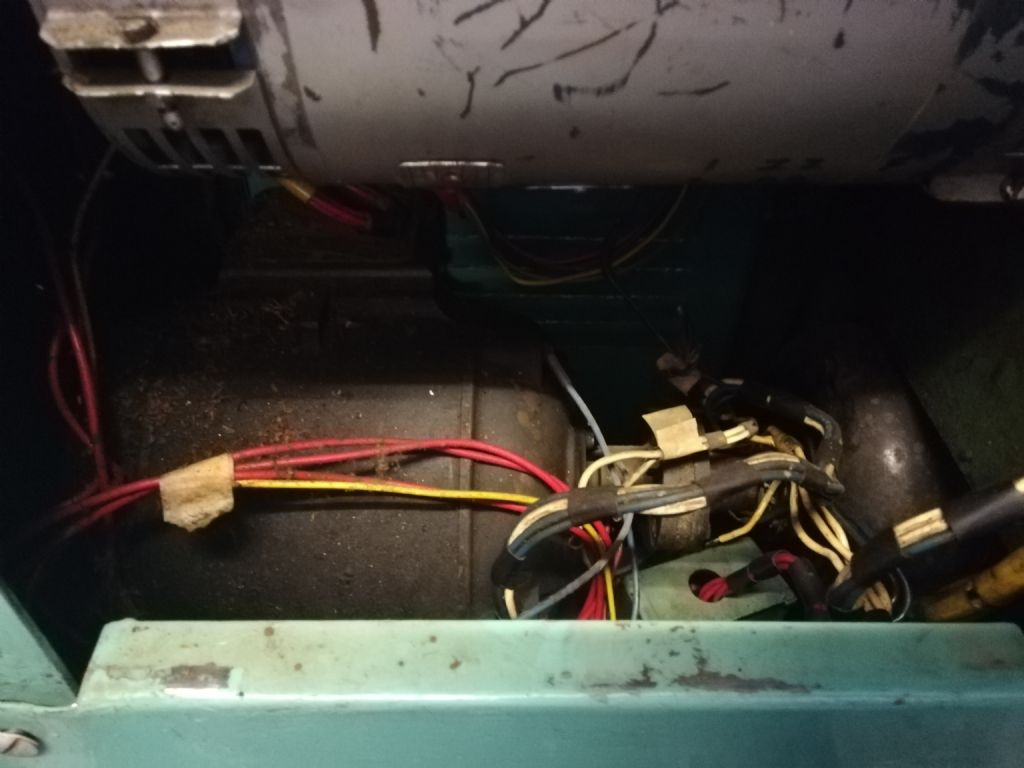

As an aside the basics of the original drive system remain. Presumable the two massive motors in the base are now redundant (I know that is a simplistic description)? Can I assume the new variable speed control bypasses the old tech – it all looks pretty crusty – allowing me to strip out and salvage the old parts?

Many thanks

Andrew

Clive Foster.