Hijack away, All the info you need is helpful and interesting to me too!

Although I've encountered more problems

I'm planning to leave my index dials just as they are, no colour, as I can read them just fine.

I'm not a fan of the Colchester green, So I'll be painting mine Colchester dove grey, but not from the paragon paints, that stuffs expensive. I found a code for dove grey BS381 694 which looks right but obviously it doesn't say Colchester. I'll probably use tractol stuff or tekaloid, I still need to decide, but I don't know the pros or cons of each. So we'll see. Need to find out soon as I need to paint my traveling steady and inevitably a lawn mower

Phil, how many liters of paint did you use for your full lathe?

The second lightbulb arrived today, first one is definitely never showing up. So I went out and plugged it in and tried it. Nothing happened, no light, no flicker. How can I start to troubleshoot it? Wiring all seems right, but i'm getting nothing. It's a very cool little bulb with lots of LEDS

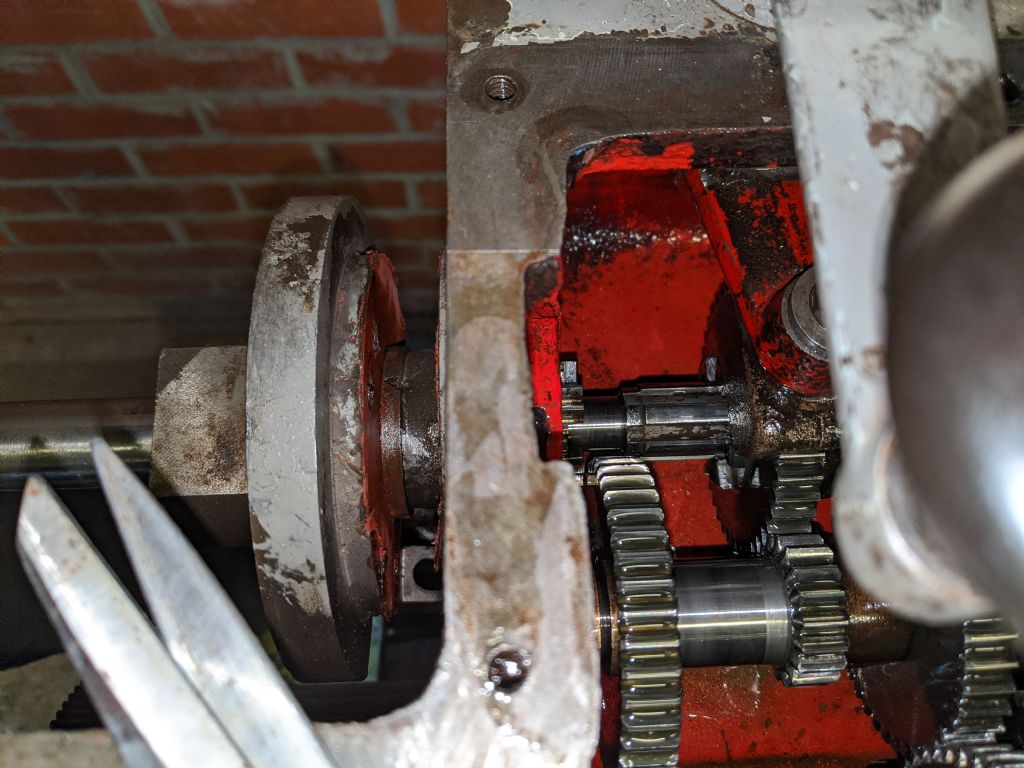

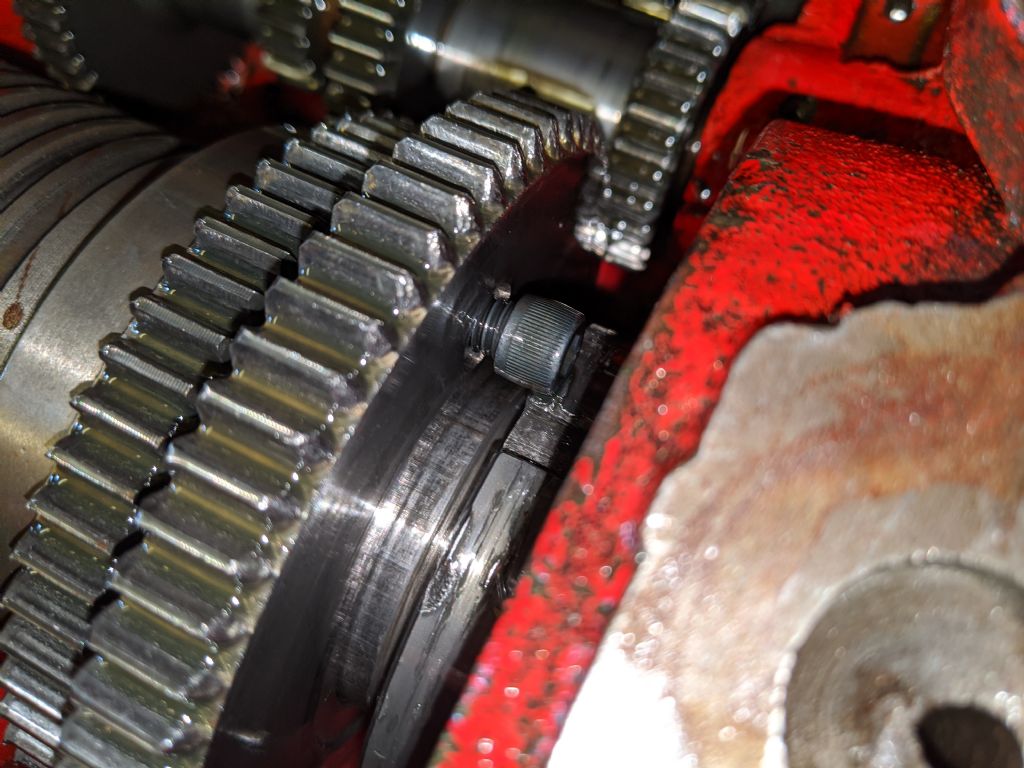

Still waiting on the oil seal, and I've ordered some loctite for the gear.

Also, I bought some steel from my local place yesterday. I'm looking forward to turning some bigger chunks. I found that only turning 1 inch or less steel, I didn't really have high enough speeds to get the correct sfpm for a great surface finish. Anyway, I made sure to get 10x50x300mm flat bar so I can make myself a ring spanner for the tailstock as I'm sick of having to keep putting a spanner on it. The lathe should have had a spanner to begin with, but mine didn't arrive with one.

Phil Whitley.