Hi Herman, Just read through your thread. I'll try to get you as many pictures as I can, maybe a video if you're able to view it like my other videos.

Is it just the wiring of the limit switches that you need?

Nice to be helping someone else out for once…

On another note, it's 3 weeks since the light bulb was posted so I've emailed asking them to send another one out.

Meanwhile, I've been enjoying putting the lathe to use. I'm definitely getting more comfortable using the machine and I'm trying to consider my accuracy.

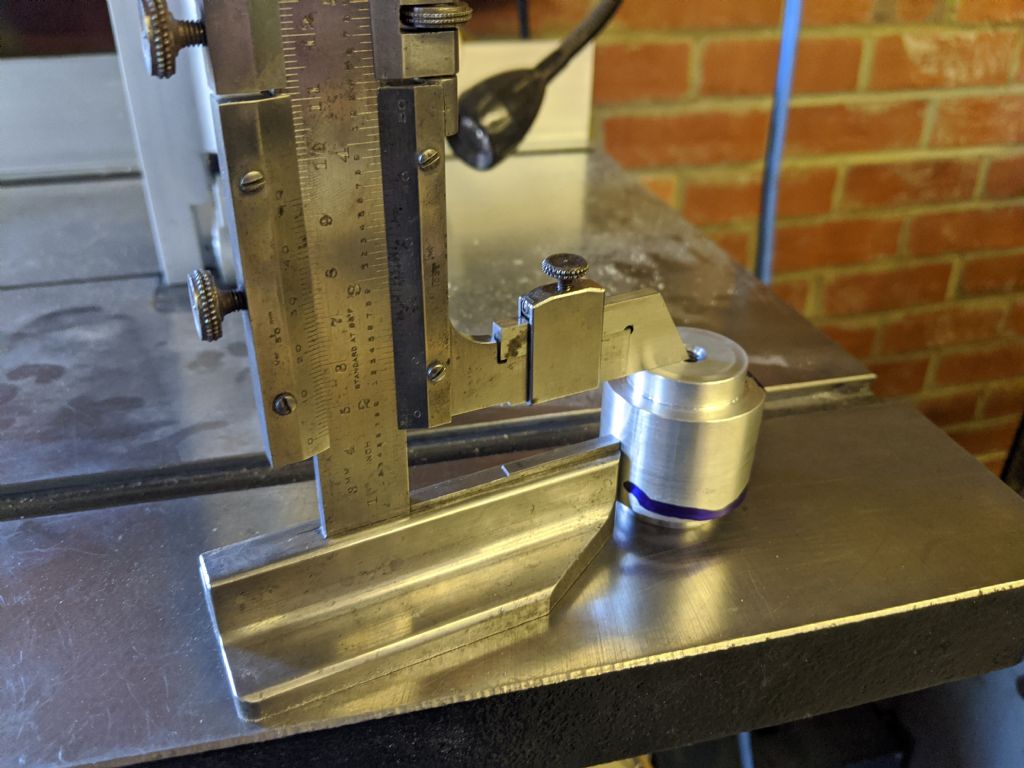

I had two hammer ends lying around, so I thought I would put them to use and make myself a small mallet from some scrap aluminium I had. I think It turned out quite nicely, even with a wood turned Bubinga handle. Not a typical mallet but interesting for me to try some setups.

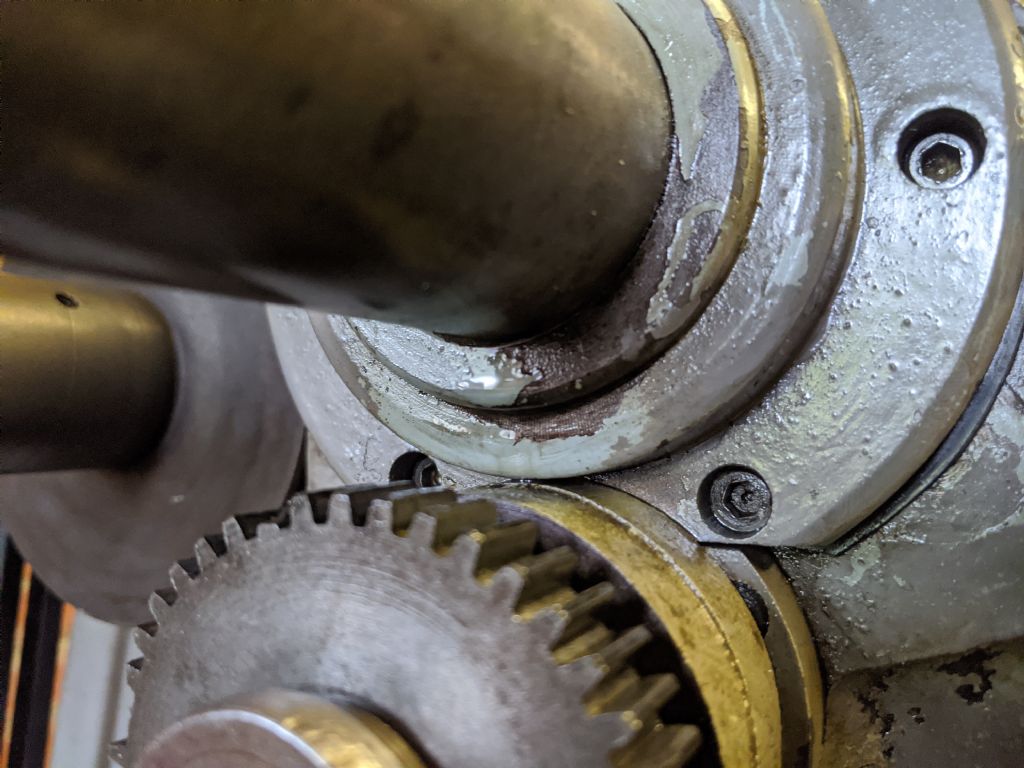

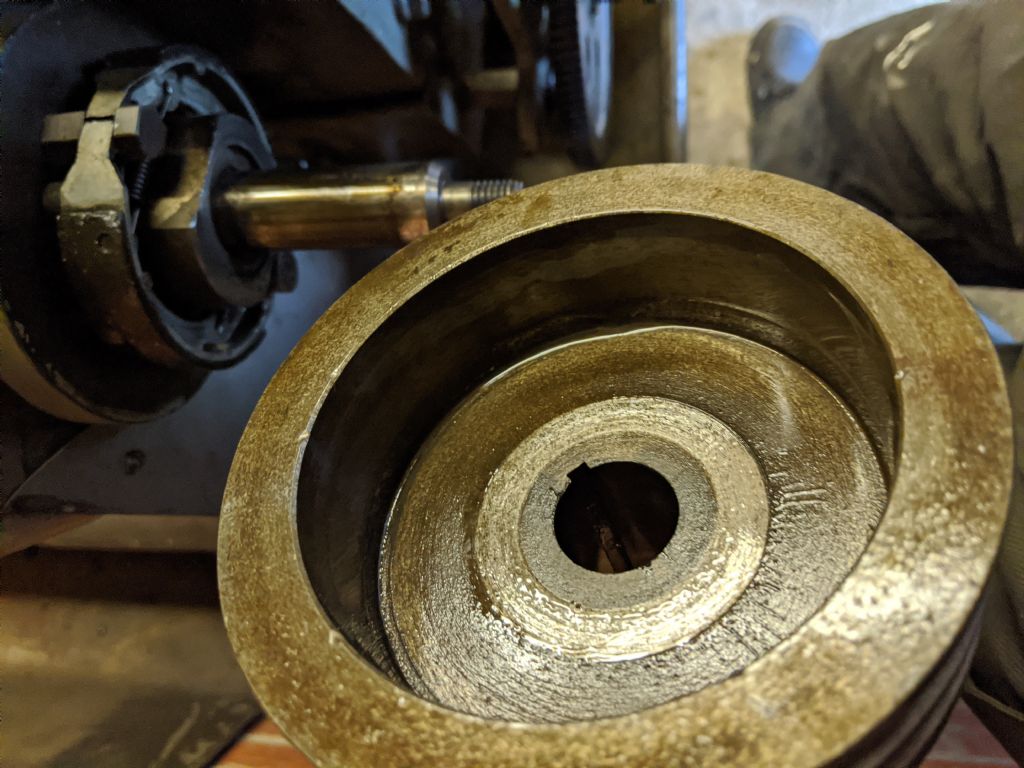

When I was tidying up the machine after, I decided to stick my hand in one of the holes under the headstock. Turned out it was absolutely full of old swarf and grime. It's made me really want to take the headstock off and clean in there, but it seems a bit excessive. Anyway, it's interesting to see all the old chips, completely steel, no aluminium, and some of the swarf must have been at least 10mm depth of cut on the radius. So more clues that the machine has been used plenty. Surprisingly I didn't find any bolts in the hole, but I did pull out loads of shavings, I can't quite reach the bottom, but the machine is probably 1kg lighter

I'll get those videos this afternoon Herman

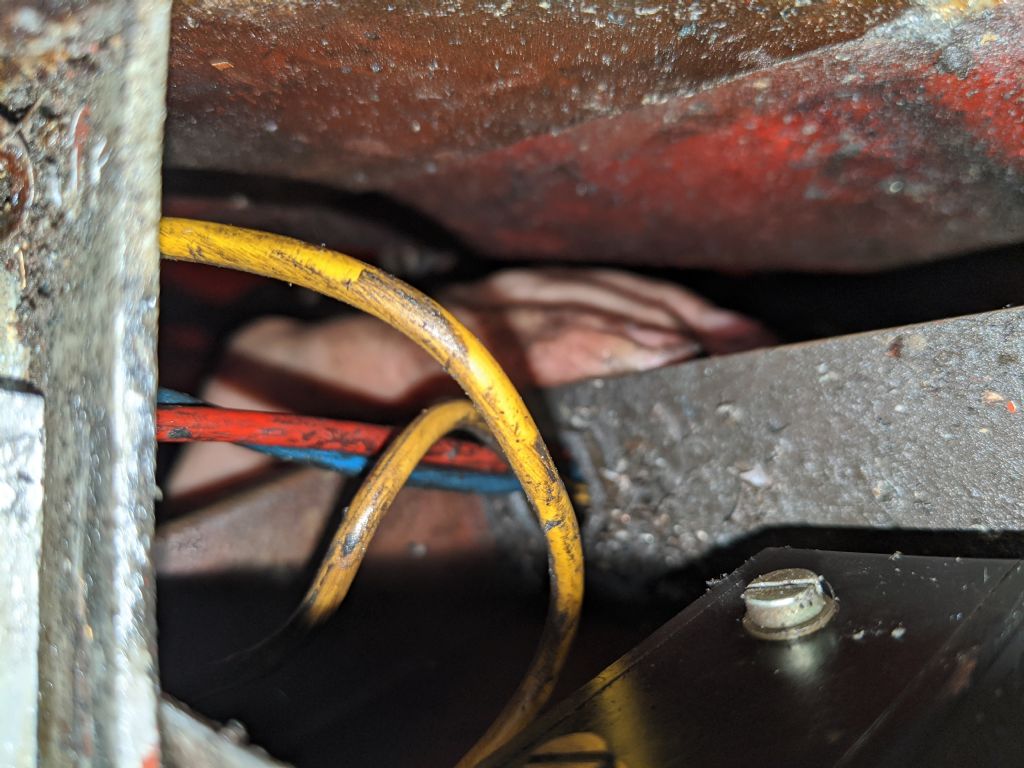

With regards to your last post on the Colchester forum, My wires are not free, they go through a pipe that goes all the way through the base of the lathe.

Edited By Richard Kirkman 1 on 08/05/2020 11:58:44

Phil Whitley.