In a former life of suffering endless report writing to which I was never fully tuned, we were encouraged to create a title that more than adequately posed the issue.

With a prompt from earlier, (good onya Michael) here’s my effort …

In clock making, how does the sweet-spot equate to the theory of cycloidal gear-meshing?

Before I reply to the above responses while risking repetition and appearing smug, my experience of clock building is a one-off skeleton clock designed by Mr John Stevens. I drilled the pivot holes into the plates before I made the wheels and pinions. Although I eventually owned a copy of ‘Watch and clock making and repairing’, by Mr W J Gazeley it was already too late to apply the recommended method of depthing.

Well may you shudder at the ugly tooth shapes I generated. Here’s the evidence …

… but it worked and they are not even cycloidal or involute.

Well, the clock ticked unaided first time around.

John, Jumping ahead, I would have been in deep poo had I been fitting ball bearings, and the clock didn’t work.

Thanks Michael on at least two counts. I forgot to mention that I had returned to applying the theory to the 290-8 wheel/pinion pair in the Wilding large wheel design, while continuing blindly to follow the BS 978 data. This latter item along with the Swiss Standard NHS 56702, 3, and 4 was presumably, developed with a great deal of cerebral input with an eye on economy. The A, B, C of tooth addenda you highlighted just adds further to the complexity of surpassing practical depthing with a theoretical solution. Also, your observations put succinctly as always, address what I’m getting at.

Roy, I fully align with your comments, if only I had more than CAD.

Martin, At a theoretical level, cos that’s all I’ve got, I imagine ‘ideal meshing’ to be a sort of sweet spot where, subjectively, the transfer of energy is both smooth and efficient. How it’s achieved at a theoretical level, I can only imagine the requirement of a high degree of complexity.

Doesn’t the variable level of friction (from [tooth] entry to exit), further complicate a definitive solution?

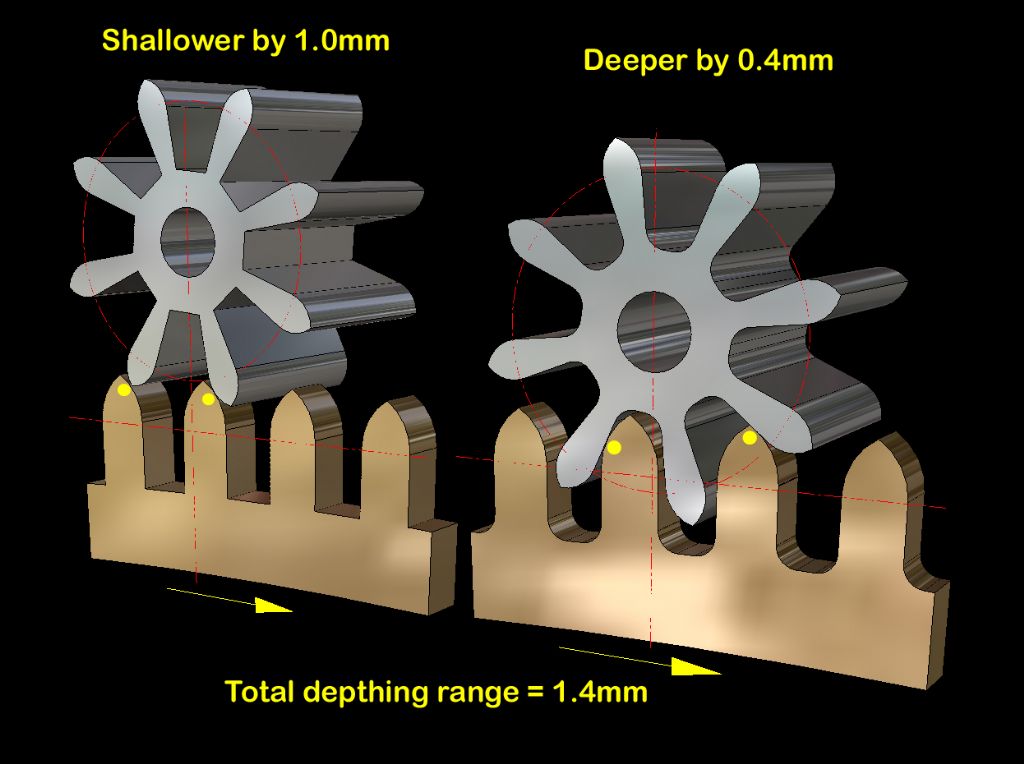

This, to some extent, repeats the questions – Is there (likely to be) much of a detectable difference between the theoretical pivot centres as per the standards and those for the sweet spot, wherever the latter may be?

What allowance for tooth wear is necessary? I’m really out of my depth (pun?) here.

Finally, an apology is required in that I failed to notice that the Swiss standards actually show a full (semicircular) root radius.

Sam

Sam Stones.