Posted by Colin Heseltine on 10/12/2018 15:00:44:

…

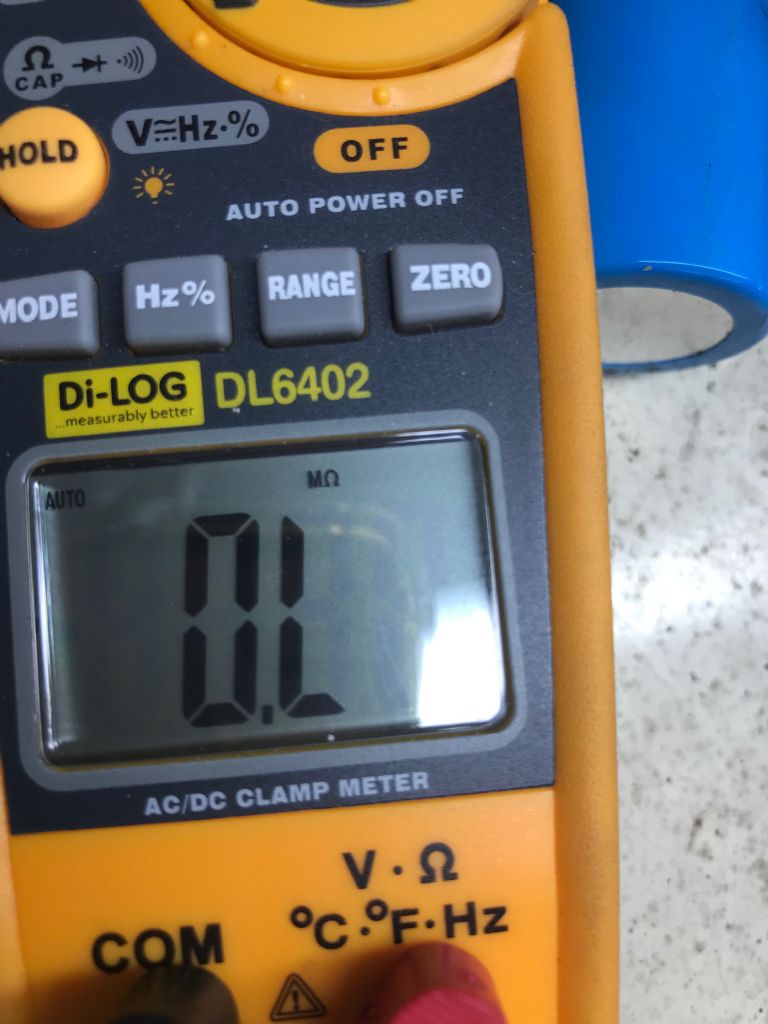

One of my testers it appears can check capacitors. The readings appear to vary. Get values from 0.18nf through to 8.16nf The display then appears to microF then shows a value of 0.

I have no idea how a nf compares to a microF

…

Probably doesn't help with your main problem but there are:

- 1000 picofarads in a nanofarad

- 1000 nanofarads in a microfarad.

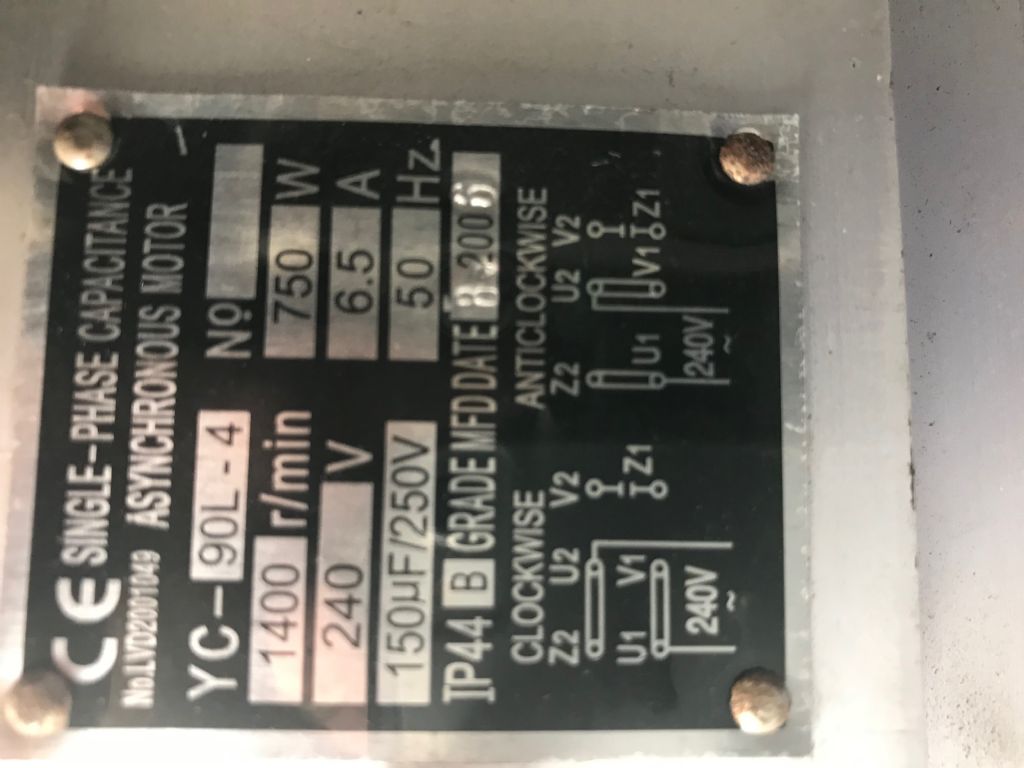

Your meter is trying to display the measurement in the scale providing best accuracy. 900nF is more meaningful than 1uF. Unfortunately capacitors are tricky beasts to measure with a multimeter. Being a low voltage device a multimeter can't test for high voltage breakdown, which is a common capacitor fault. Also the test leads have to make a good sustained contact with the terminals. Any wobble or dirt and you will get duff readings. And, because of the simple way the test is done by the meter a faulty capacitor can thoroughly confuse it. The scale jumping about and/or getting different answers is typical of bad tests as well as a sick capacitor.

The other major problem is that it's very difficult to measure a capacitor if it's wired into a circuit. At least one terminal has to be disconnected to get a meaningful reading, ideally both. If you don't take a clean reading then the meter is likely to be completely discombobulated by whatever else is wired to the capacitor. As there's so much opportunity for being misled. I believe motor repairers are more likely to instantly replace an even slightly suspicious capacitor than to mess around trying to measure it.

Given all these shortcomings you might wonder if capacitance ranges on a multimeter are worth having at all! Mine is mostly used to check brand-new components, not because I suspect they're faulty, more as a quick way of confirming they're the right value – the printing is tiny.

Dave

Edited By SillyOldDuffer on 10/12/2018 17:46:41

Jon.

f:0″>https://www.ebay.co.uk/itm/Motor-Start-Starting-Capacitor-150uf-150mfd-microfarads-230V-250V-300V/122735905448?hash=item1c93a14aa8:g

f:0″>https://www.ebay.co.uk/itm/Motor-Start-Starting-Capacitor-150uf-150mfd-microfarads-230V-250V-300V/122735905448?hash=item1c93a14aa8:g asAAOSwlHBZ0hn1:rk:3

asAAOSwlHBZ0hn1:rk:3