John M,

Few points:

– the first and last time your machine was probably 'trammed' was just before it left the factory.

– Tramming is a skill in itself. If you are not sure, leave it alone and get on with milling (and I know that this is against popular advice). In the old days, a machine tool fitter would have been sent with the machine to do the necessary, before the user got on with using a mill. This is out of question for a lovely cheap machine. Also, as far as I am concerned, most of the great machine tool fitters have progresses into heavenly pastures. Handful exist, rest of us have to experiment, and very few are gifted with perfecting this area, especially when it comes to scraping or shimming. YouTube is full of good, bad and ugly.

– If you are intending to shim, it should be between the columns base, and the base casting. Keep in mind, if you shim in one location, it will effect other positions – i.e. left/right, front/back. If you are lucky, all will go well until the next time you tilt the column. Best to never tilt the column, if and once you have set it. Forget about scraping at the moment.

– If you do not want to shim the column to the base, and if your work is critical, consider shimming the work piece onto the milling table, as many do, especially in the U.S.. Some on here consider that option to be sacrilege.

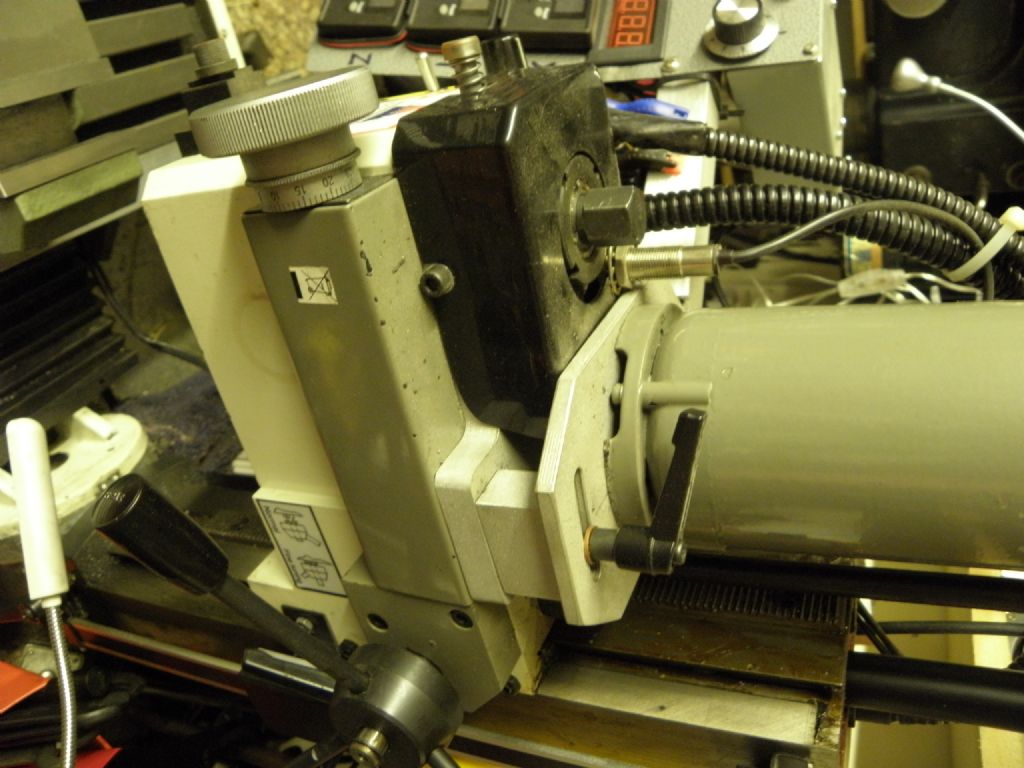

– Flexing of the column/head: You said that you have locked the Z axis gib. That's good. I presume that the big locking nut at the back of the column is locked too – i.e. well tight. Leaning/pulling of head will bring about a certain level of flex, especially with the type of column you have. Note: before anyone tells you otherwise, you will find this if you lean on a Bridgeport head too.. be it less, due to more rigidity. Solutions exist from doing what Neil Wyatt did to various others – be they good or bad, to changing the column to a fixed column. All such options will reduce the flex, but not remove them completely. As I said, you can lean on a Bridgeport head too and there will be a small degree of movement, and I don't care if someone tells you otherwise.

Keeping above in mind, 'zero' everything the best you can without addition of shims or anything, and start using the machine. Next, keep the flexing in mind, and avoid 'forcing' anything during the milling process, keeping within the limitations of the machine. Note: as originally supplied – with the tilting column, there are hundreds of thousands of such mini-mills around the world, doing the same job, since 1986 (around the time they were born I think), with good, bad and ugly results, depending on many factors, including how good/bad/ugly/heavy handed the users is.

Once you start using the machine, You will start getting a real idea of niggles. When dealing with niggles, deal with one niggle at a time. Avoid dealing with all of them at the same time. Identifying and dealing with a niggle will only come with experience over time…. for your particular requirement. Sometimes, a niggle is not really a niggle/issue, but usually blown out of all proportions…. especially on You Tube… by those blessed with low or no mechanical knowledge, or idea of limitations of the machine. There are still a few on You Tube who do have a clear understanding, and they do do things to the machine to meet their particular needs.

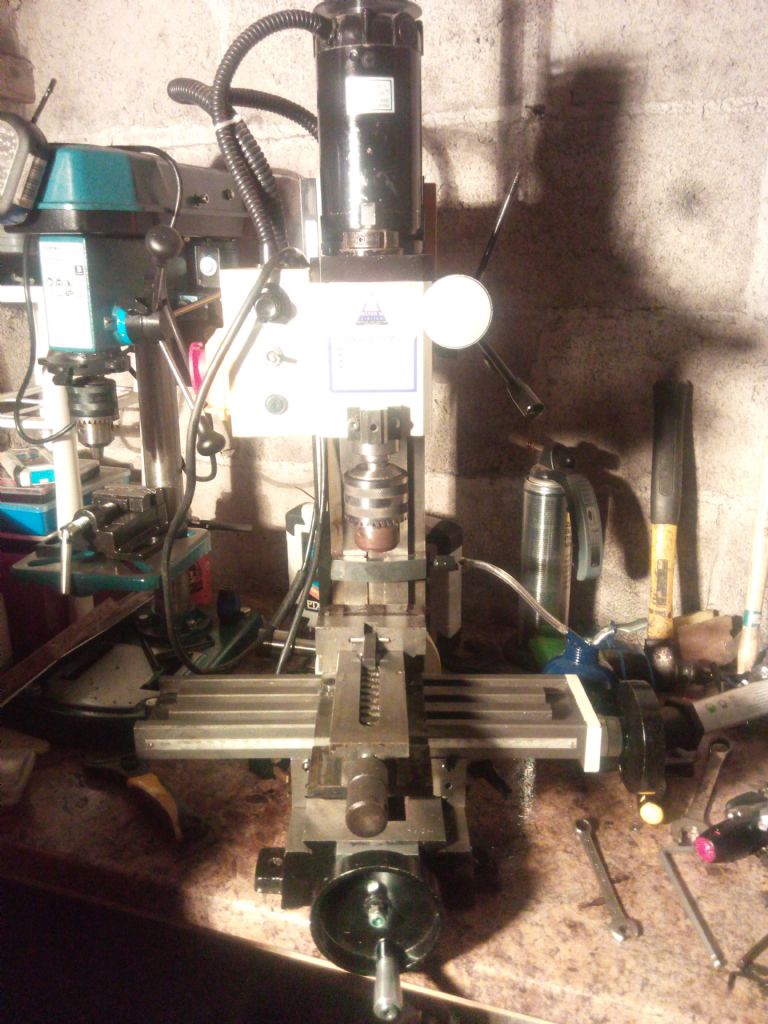

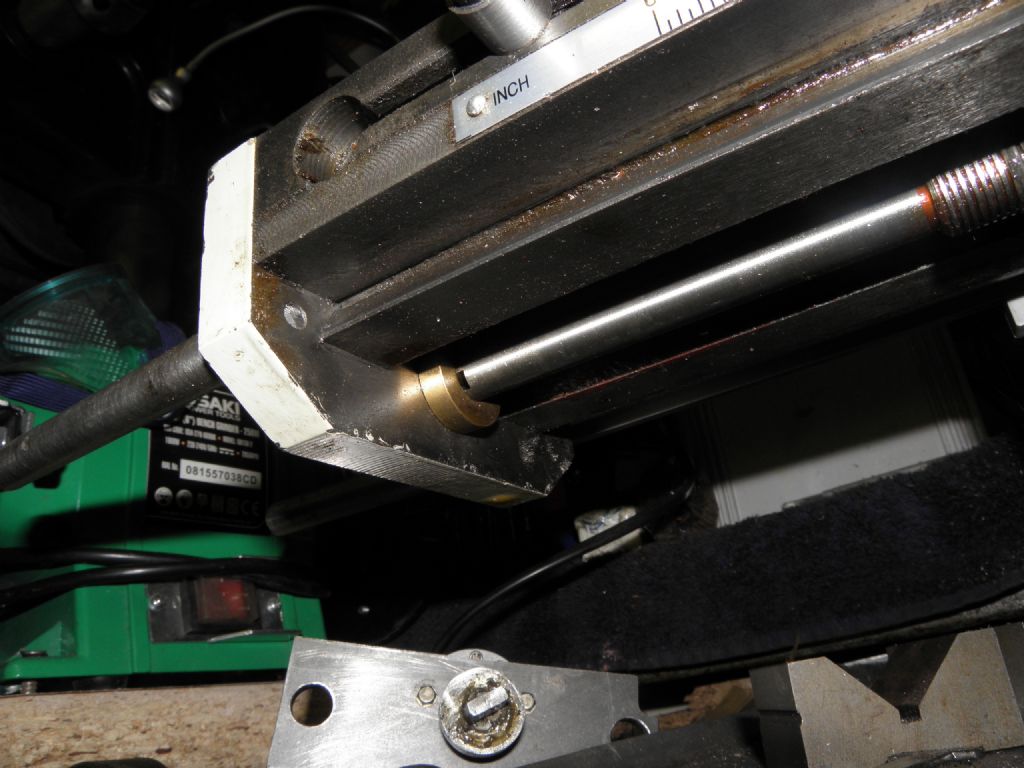

Anyway, do consider getting or making the left hand table bracket/mount. Looking at some of the pictures, it would seem that it is important to support the X axis screw in the case of your machines table.

Ketan at ARC.

John Murphy 3.