No-one has mentioned decent dust extraction as being a solution to most of the problems of dust and debris. A powerful extractor designed for wood dust transforms the experience by removing much (but not quite all) of the dust. The challenge is in arranging the nozzel near enought eh surface of the work, and making it traverse with the toolpost/carriage. I use an 2HP Axminster unit which operates on the "vacuum" principle. I have also used an earlier unit based on lower suction at the nozzle, but intaking larger volumes of air. The vacuum does the job for my kind of work, but must have a small nozzle positioned close to the work surface. That just leaves a bit of dust, which, while requiring clean up is not a great problem. Cleaning the bed of the usual oily film before turning wood is essential. Cleanu up of chuck etc is important, but no worse than when turning cast iron etc.

The comments on speed etc are valid, especially for small diameter work.

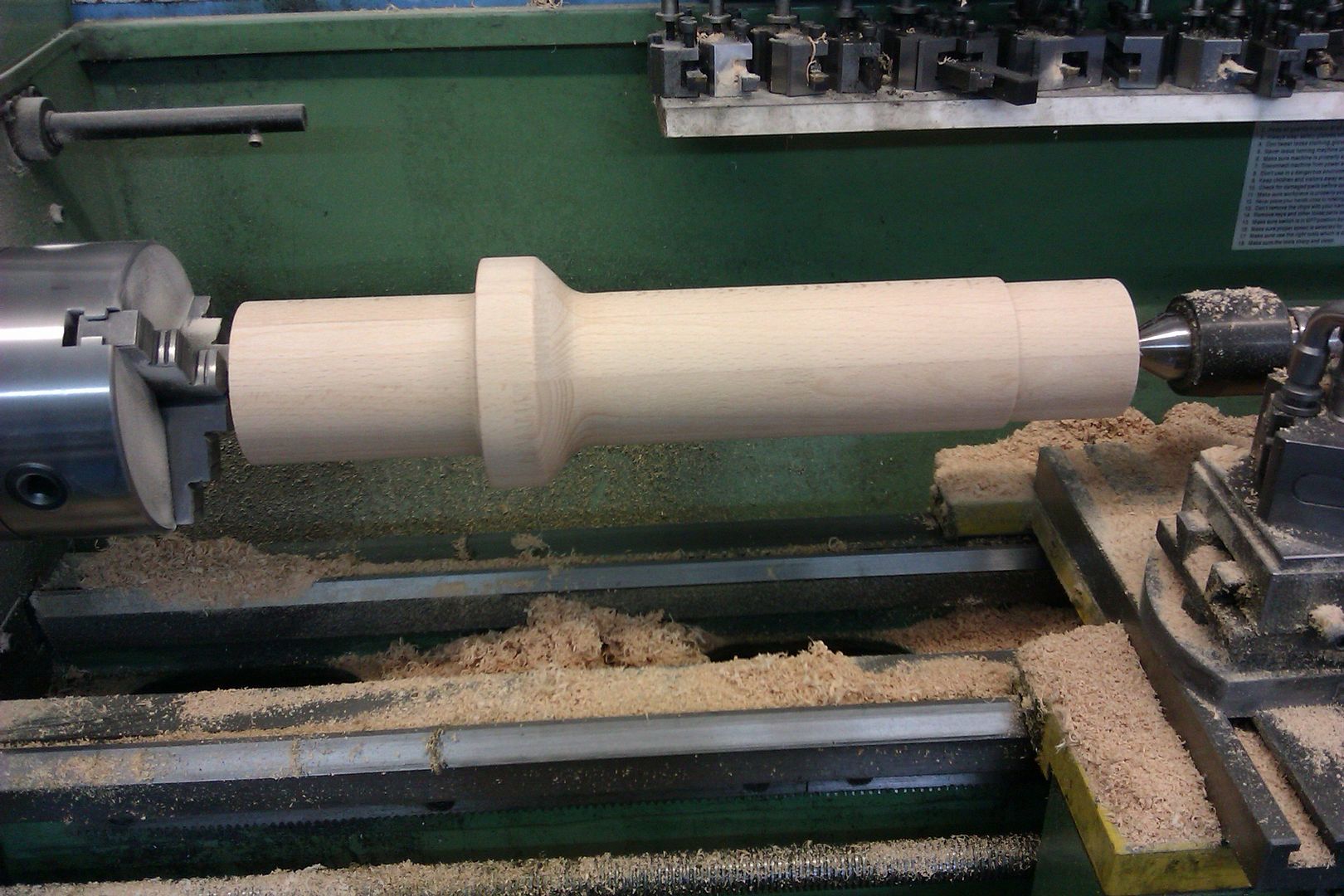

A lathe is a lathe, and I never could really understand how a woodturner could claim a wood lathe was better for tunring wood. To me (and I own a wood turning lathe too) the engineer's lathe has proper precise control of carriage and cross-slide, meaning one can turn wood precisely parallel and to size. Sure; it shrinks and moves later, but that's the wood, not the lathe. My wood lathe says under the bench, out of the way.

Boxford made two wood turning tool rests(short one and long one) to fit the old bench lathes (AUD, BUD etc) but ther are designed to fit the old-style rest-holding arrangements which use a tapered plug. It is easy to make a simple adapter to allow those rests to fit onto a plain surface or a tee slot etc. I suggest second-hand dealers (see G & M Tools, for example). It is also relatively easy to adapt other rests, and I often use a rest from a Record wood lathe to give me an extended rest which sits out a distance from the normal rest position, for larger jobs.

One other word of caution. It is worth pointing out the dangers of wood dust from some species of trees, as well as the general danger to the respiratory system from small wood dust particles. I have found this is not to be underestimated. The same is true for other materials, of course, but the species-related dangers are both real and well documented. Real woodworkers cheerfully ignore dust masks, goggles and ear muffs – but they are all dead, blind or deaf, so I guess they knew best.

Marcus

John McNamara.

exceeded my bed length so I drilled two holes in the end of the bed and bracketed out a ball bearing centre. I also had to conjure up a fixed steady that did not mark the wood. It all worked very well.

exceeded my bed length so I drilled two holes in the end of the bed and bracketed out a ball bearing centre. I also had to conjure up a fixed steady that did not mark the wood. It all worked very well.