Thanks for the lowdown fellas, not that I’ve managed to find any of these screws yet but at least I now know what they are called.

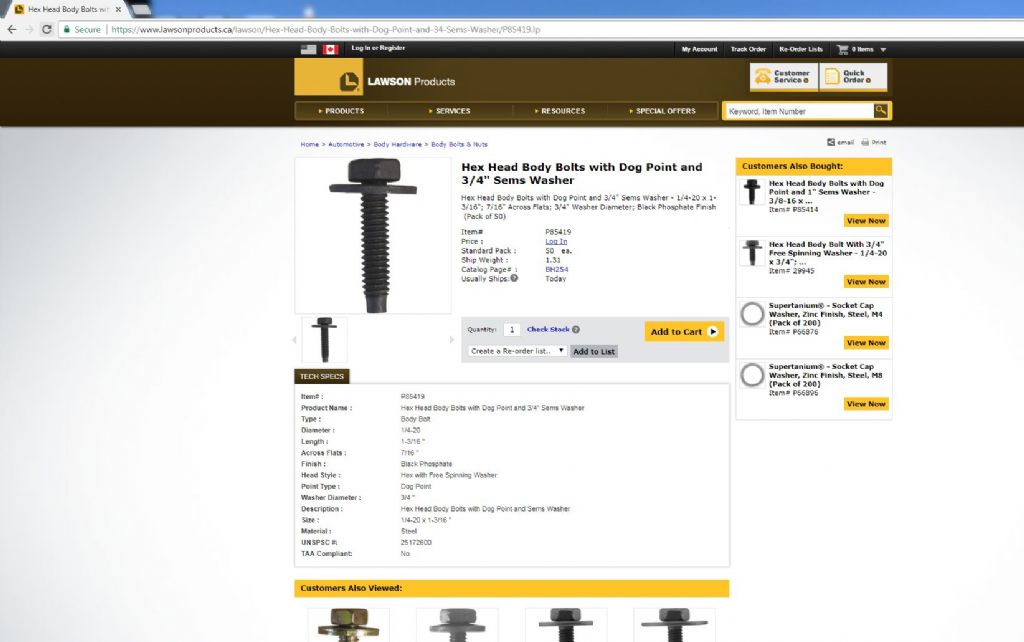

Just to put you in the picture not exactly model engineering I know, I’ve just removed a 3.5mm thick steel plate from under my car, the plate protects the front axle and it’s bolted to the chassis using hexagon head screws which have a very short shank with a plain and spring washer encapsuled on them and as I’ve just found out from yourselves a dogpoint at the end of the thread.

The car chassis is a rectangular box type section with nuts which are welded to the inside of the boxing, they are not caged nuts but welded on as I say.

I don’t suppose the world would come to an end if I used ordinary setscrews of which the thread size is metric fine M10 x 1.25 pitch.

I don’t have a metal turning lathe but I guess I could put a couple of nuts on the screws using them as a register and file a dogpoint on them if I had to.

I had to use a blowlamp and keep heating the screws up in order to screw them out and even then the creaked like hell coming out, but If I hadn't have heated them I guess they would have sheared off.

What is the opinion on using ordinary setscrews, obviously with the correct size thread? and Jeff you blew me away with what you have said, so I sure would like to hear what you have to say concerning my application.

Thanks again fellas

Clive B 1.